Other bamboo furniture products are beds, cupboard, table, upholstery chairs [75], ply bamboo, laminated bamboo, mat ply bamboo, curtains ply bamboo, laminated bamboo strips, mat curtain plywood, bamboo chipboard, floor tiles and composites. Mine Kafon is a revolutionary landmine clearer/detonator that is very cheap to make. Artists of this continent have refined techniques that qualify these products to exigent markets. The mechanical properties of bamboo are strongly affected by the age, species and humidity.  Most of the manufacturers use this process as it requires not only a little time to yield the bamboo fibres but also less economic means mainly when compared with mechanical methods. We are a community of more than 103,000 authors and editors from 3,291 institutions spanning 160 countries, including Nobel Prize winners and some of the worlds most-cited researchers. Bamboo paper has the same quality with paper made from wood. A total of 40 of the 43 species found in Africa are majorly distributed in Madagascar while the remaining 3 species are found in mainland Africa.

Most of the manufacturers use this process as it requires not only a little time to yield the bamboo fibres but also less economic means mainly when compared with mechanical methods. We are a community of more than 103,000 authors and editors from 3,291 institutions spanning 160 countries, including Nobel Prize winners and some of the worlds most-cited researchers. Bamboo paper has the same quality with paper made from wood. A total of 40 of the 43 species found in Africa are majorly distributed in Madagascar while the remaining 3 species are found in mainland Africa.

In Latin America, farmers often use bamboo as beehives. Percentage of world bamboo resources by continent [14]. The demand for a substitute to resources associated with environmental problems has brought about a strong interest in the use of raw materials and products that are renewable, sustainable and biocompatible. The increased content of the coupling agents used increased the morphological and mechanical properties of composites.

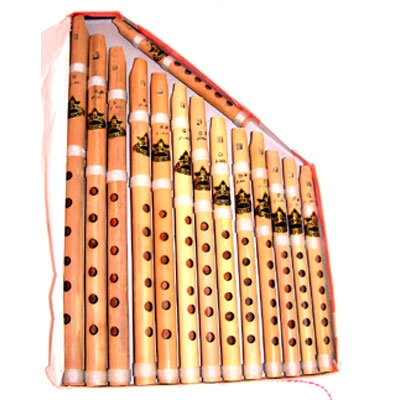

Table 5 shows some typical bamboo species and parts used for this purpose [78]. Its use varies from domestic household products to industrial applications, from medicine to nutrition and from toys to aircraft production. Many bamboos are popularly used as ornamental plants to beautify homes and gardens. Although some of these applications are very limited in scope, continuous researches on bamboo can increase their potential and induce their aggressive interest in many more areas. The comparison of alkaline and acetylating treatments showed that the mechanical properties of bamboo fibre-polypropylene composites were improved and adhesion between bamboo fibre and polypropylene matrix was enhanced. Love podcasts or audiobooks? The obtained pulp was cooled, filtered and washed, and then further treated with glacial acetic acid. The various uses of bamboo for humans are quite remarkable. Dilute acid pre-treatment of bamboo shoots shell fibre (BSSF) and bamboo stem and leaf (BSL) have been investigated for xylose and glucose yields [42]. Bamboo internodes (the part between 2 nodes) of larger diameter bamboo species such as Guadua angustifolia or Dendrocalamus asper are very well suited to make a bamboo beehive. Sodium chlorite was occasionally used to bleach the fibre to white. Bamboo is known as one of the materials more versatile to the handicraft production because it is a raw material of easy acquisition, low-cost and demands simple tools in preparation. After their unique premium sound system made from bamboo charcoal, bamboo fibre and resin, Lexus has now revealed their newest invention: the Bamboo Steering Wheel! British expats are hoping to ease traffic congestion, parking and pollution problems with their new eco-friendly "Bamboo Treecycle" invention which is proving to be a big hit. Countries with the largest bamboo resources in the world [15]. Its natural hollow form makes bamboo an obvious choice for manytraditional instruments such as a wide variety of flutes, but because of the excellent sound properties of solid bamboo panels it is now also used for making modern guitars. This is due to the nutritious and active minerals (such as vitamins, amino acids, flavine, phenolic acids, polysaccharide, trace elements and steroids) they contain [76].  An HNO3-KClO3 method has also been used to extract fibre from bamboo samples. ATRP is a technique, which could allow the incorporation of polymers with predetermined molecular weight onto the surfaces of particles, fibres or membranes. Studies have also revealed their uses as absorbent for dyes [82, 83, 84, 85], heavy metal [86, 87], organic pollutants [88] and other substances [89, 90]. Fact is, everything that can be made from wood can also be made with bamboo. Pre-treatment of bamboo (Dendrocalamus asper) with dilute sulphuric acid before enzymatic hydrolysis process to produce fermentable sugars has also been investigated [38]. Silane coupling agents have a hydrophilic structure with different groups attached to the silicon atoms that can act as a bridge; one end is interacting with the matrix and the other end reacting with the hydrophilic fibres [64]. [21] reported that bio-ethanol production from bamboo can also follow the general process for ethanol production from other lignocellulosic materials, which including pre-treatment, enzymatic hydrolysis and fermentation. The interfacial adhesion between the fibre and other matrices can enhance the inclusion of coupling agents and fibre pre-treatment using acid hydrolysis. It has been recognised as a useful resource for this purpose due to its higher growth rate, annual biomass yield and significant amount of sugars [2, 21]. Acrylonitrile treatment of bamboo fibre has been reported to improve the tensile, flexural and water absorption properties of acrylonitrile-treated bamboo fibre composites [49]. Bamboo is considered an alternative to wood owing to their excellent qualities in physical and mechanical attributes [23]. It is one of the fastest growing plants [8]. Cellulose, hemicelluloses and lignin are the three major chemical compositions of bamboo, and they are closely associated in a complex structure [31]. [8, 12, 13]. Its based on principles of collaboration, unobstructed discovery, and, most importantly, scientific progression. Besides, it is recognised as an industrial raw material globally and has tremendous potentials for economic development of nations [75]. Imagine if all Central and South American homes, offices and sheds would use corrugated roofs made from bamboo instead of zinc or plastic, and imagine if all these roofs were produced from locally available native bamboo forests and plantations. It was thought that effective surface treatment from the silane coupling agent-improved adhesion between the polylactic acid matrix and the bamboo fibre.

An HNO3-KClO3 method has also been used to extract fibre from bamboo samples. ATRP is a technique, which could allow the incorporation of polymers with predetermined molecular weight onto the surfaces of particles, fibres or membranes. Studies have also revealed their uses as absorbent for dyes [82, 83, 84, 85], heavy metal [86, 87], organic pollutants [88] and other substances [89, 90]. Fact is, everything that can be made from wood can also be made with bamboo. Pre-treatment of bamboo (Dendrocalamus asper) with dilute sulphuric acid before enzymatic hydrolysis process to produce fermentable sugars has also been investigated [38]. Silane coupling agents have a hydrophilic structure with different groups attached to the silicon atoms that can act as a bridge; one end is interacting with the matrix and the other end reacting with the hydrophilic fibres [64]. [21] reported that bio-ethanol production from bamboo can also follow the general process for ethanol production from other lignocellulosic materials, which including pre-treatment, enzymatic hydrolysis and fermentation. The interfacial adhesion between the fibre and other matrices can enhance the inclusion of coupling agents and fibre pre-treatment using acid hydrolysis. It has been recognised as a useful resource for this purpose due to its higher growth rate, annual biomass yield and significant amount of sugars [2, 21]. Acrylonitrile treatment of bamboo fibre has been reported to improve the tensile, flexural and water absorption properties of acrylonitrile-treated bamboo fibre composites [49]. Bamboo is considered an alternative to wood owing to their excellent qualities in physical and mechanical attributes [23]. It is one of the fastest growing plants [8]. Cellulose, hemicelluloses and lignin are the three major chemical compositions of bamboo, and they are closely associated in a complex structure [31]. [8, 12, 13]. Its based on principles of collaboration, unobstructed discovery, and, most importantly, scientific progression. Besides, it is recognised as an industrial raw material globally and has tremendous potentials for economic development of nations [75]. Imagine if all Central and South American homes, offices and sheds would use corrugated roofs made from bamboo instead of zinc or plastic, and imagine if all these roofs were produced from locally available native bamboo forests and plantations. It was thought that effective surface treatment from the silane coupling agent-improved adhesion between the polylactic acid matrix and the bamboo fibre.

After treating for 24h at 50C, the obtained bamboo fibre suspension was cooled then dialysed against distilled water to remove low molecular weight compounds. Some materials extracted from bamboo are used in fresh flavour and preservation of food. A number of researchers have also produced bamboo ethanol and butanol. It has been extensively studied for graft copolymerization of vinyl monomers onto fibres in a living/controllable way [65]. Bamboo is found in abundance in Asia and South America [11]. It serves as a substitute for wood charcoal or mineral coal and has been reported to possess absorption capacity which is six times that of wood charcoal of the same weight [3, 14]. Several studies were conducted on physical and mechanical characteristics to test the bamboo as construction material. The common species of bamboo for this purpose are given in Table 5.

Some bamboo-based products include house construction materials, household items, biofuel, chemical and pharmaceutical products, pulp and paper, irrigation and drainage pipes and textiles materials, panels, flooring materials, charcoal, edible shoots and other daily-use articles [75, 77]. Apart from the above, several other applications exist, though on a relatively small scale. In another interesting study reported by Kumar and Kumar [50], alkali treatment of bamboo fibre further increased the tensile and flexural strength of bamboo-epoxy nanocomposites by 60 and 42%, respectively, as compared to pure composites. Bamboo leaf contains 25% flavine and phenolic compound that have the power to remove active oxy-free radicals, stopping nitrification and abating blood fat. Some minor applications include the use of its leaves for medical purposes, fresh edible shoots and culms for timber or as a raw material for pulping [8]. They present versatile structure produced by physical and mechanical properties and low specific weight [2].

Afghani designer Massoud Hassani invented a wind powered bamboo minesweeper that can potentially save thousands of lives. The chemical composition of bamboo is known to be similar to that of wood, but bamboo has a higher content of minor components compared with wood [32]. Besides, bamboo is also a material of high plasticity and easy to combine with other materials. Bamboo textiles present many solutions to the present unsustainable nature of textile engineering as bamboo is a renewable resource that yields 50 times as much fiber per acre as cotton. This goes from construction materials to food, medicine, musical instruments, fabrics, paper pulp, fencing, basketry, utensils, bicycles, and so on Therefor te better question would be: What products cannot be made from bamboo? Crude fibre bundles of bamboo, obtained by drawing bamboo chips roasted at 150C for 30min, were first immersed in water at 60C for 24h, and then air-dried before removing impurities further by repeated rolling. Various bamboo furniture products including bamboo panel, composite board and particleboard have been developed in China [76]. In addition, with adequate technology, the stems can be used in the production of cellulose, bio-ethanol and starch [21]. In rural Tanzania, a bamboo pipe network is being used for providing safe and constant water supply to a large rural population [102]. The leaf bud of B. spinosais used in leprosy, fever and haemoptysis.

However, cost, energy, water, and chemical concerns in manufacturing still must be addressed. After treatment with 0.5% sulphuric acid solution for 10min and then being emulsified for 5 days, refined bamboo fibre was obtained. [67] carried out a comparative study on the effect of alkali soaking, silane coupling agent and maleic anhydride grafting on the mechanical properties of cellulose/poly(l-lactic acid) composites. *Address all correspondence to: mayowa.azeez@eksu.edu.ng. In India, young and tender bamboo shoots are used as a seasonal vegetable in both rural and urban areas [78]. on an eroded slope), and its root structure remains intact after harvest, thus, generating new shoots [24]. Kumar etal. What products are made from bamboo? The multi-functional ranges of bamboo uses have shown that it may prove beneficial as a valuable and sustainable natural resource [76]. Today we see a boom of innovative bamboo products and applications as a sustainable alternative for wood. In another study, Azzini etal. In addition, the excellent properties of bamboo enhanced via different chemical modification methods to improve their mechanical and thermal makes their fibre to be competitive with other materials used in the reinforcing of different polymers.

After being washed with hot water, the fibres were treated with 0.04% xylanase and 0.5% DTPA (diethylene triamine pentaacetic acid) at 70C for 60min at a pH of 6.5. This suggests that the fibre in the bamboo leaves enlarge the digestive tract and enable the chicken to consume more and grow faster. Bamboo serves as an excellent alternative to wood in the manufacture of furniture. Among many other discoveries, he described how the Chinese used and manufactured bamboo cables for towing boats. Drainpipes made from bamboo serve as low-cost substitute to those made from assorted materials. Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too. Bamboo provides food, shelter and medicine and serves as raw material for many industries. The burnt roots of this species are used to treat ringworm, bleed gums and painful joints. One pot synthesis generated the coupling agents. At present, the bamboo utilisation in construction is of subjective form and based generally in traditional systems established in each country. The area covered by bamboo in Africa has been estimated at 1.5 million ha with about 43 species [10, 16]; that of Myanmar has been estimated at 2.2 million ha and that of India estimated between 3 and 20 million ha [17]. It can be used for almost all parts of houses, including posts, roofs, walls, floors, beams, trusses and fences [14]. Bamboo, a perennial woody grass belonging to Gramineae family and Bambuseae subfamily, is ubiquitous in many parts of the world. It has been reported to include natural products, such as potassium, carbohydrates, dietary fibres, vitamins and other active materials, which are used for traditional food in many countries [79] and further conversion of these carbohydrates, give rise to other products like xylitol. Home > Books > Bamboo - Current and Future Prospects, Submitted: October 6th, 2016 Reviewed: March 9th, 2018 Published: May 30th, 2018, Total Chapter Downloads on intechopen.com. Bamboo shoot is one vegetable that is free in pollution, low in fat and high in edible fibre and rich in mineral. Usually, there is variation in the chemical composition of bamboo depending on their age. Figures of nutrient contents of Bambusa vulgarisshow it to contain crude protein (10.1g), crude fibre (21.7g), ether extract (2.5g), ash (21.3g), phosphorous (86mg), iron (13.4mg), vitamin B1 (0.1mg), vitamins B2 (2.54mg) and carotene (12.3mg)/100g). The liquor ratio was 20, and the pH was maintained at 10.5. SEM studies carried out showed a better dispersion of fibre into the PVC matrix due to an increased amount of coupling agents used. In Asia, bamboo is quite common for bridges, scaffolding and housing, but it is usually a temporary exterior structural material. Bamboo fibres could also be modified by atom transfer radical polymerisation (ATRP) technique. In a study reported by Akinbile etal. As many cups as possible can be taken as bamboo tea stimulates metabolism without side effects [3]. The treatment of bamboo strips with low molecular weight phenol formaldehyde (LMwPF) resin followed by pressing at 140C improved the dimensional stability and strength properties of the strips. Li etal. Many research and technical works have been carried out on the chemical modification of bamboo fibres to improve their properties for specialised applications [43, 44, 45, 46]. It has been found out that from 4 tons of bamboo nearly 1 ton of pulp is produced which is utilised in different furnishes for production of paper and board [78]. The part transformed to alcohol represents the yield of 250380l ton1 of bamboo [94] while that of sugar cane, when compared gave an average yield of 70l of alcohol ton1 [95]. Because of its excellent characteristics, some countries are renewing their bioenergy strategies to include bamboo. Its brightness and optical properties remain stable while those papers make from wood may deteriorate over time. To date our community has made over 100 million downloads. With its high growth rate, a wide range of applications and renewability, bamboo resources occupy a noteworthy position in the twenty-first century as a versatile and vital raw material [20]. Bamboo is a lignocellulosic biomass from which some value-added products can be obtained. Although data on worldwide production of bamboo products are incredibly unreliable, they do not appear in significant commodity databases [8]. The alkali-treated fibres are then passed through multi-phase bleaching. Read on and discover some of the coolest bamboo products you probably didn't even know they existed!

Other common species of bamboo used for this purpose are shown in Table 5.

Learn on the go with our new app. The silane-treated bamboo fibre-reinforced polylactic acid composite showed excellent mechanical and thermal properties compared with the properties of polylactic acid composite containing delignified BF. Butanol is similar to ethanol being a form of alcohol. A few examples of bamboo paper products are coffee filters, paper cups, paper towels, toilet paper, cardboard, kraft paper, and bond paper. In China bamboo fiber has been used to make paper since early times, but in recent years, bamboo has emerged as an important raw material for the pulp and paper industry due to the shortage of wood resources. The percentage of world bamboo resources by continent is shown in Table 2 [14] and the countries with the most abundant bamboo resources are shown in Table 3 [15].

The Japanese have used the leaves of bamboo as fodder for livestock for hundreds of years. Traveler | Ex-pat | Failing polymath | Career generalist | Frumpy snarky dude whos interested in far too many topics | PB&T creator | Top 1000 Writer. They prepared two sets of bamboo-epoxy composites, one with silane treatment bamboo mats and the other with silane treatment mercerised bamboo mats. This siliceous material is used as a cooling tonic and aphrodisiac, as a remedy for asthma and coughs [98] and other debilitating diseases. Other bamboo products include bio-methane, flavonoids and functional xylo-oligosaccharides. Bamboo fibres have great potential as an alternative to inorganic fillers and are raw material for fabricating a composite material, and their applicability is being widely investigated. These constituents play an important role in physiological activity of bamboo, and they are found in cell cavity or special organelles [15]. As a typical forest plant in the tropical and subtropical area, bamboo forest plays significant roles in its biological characteristics and growth habits. The aboveground biomass of bamboo in the Philippines was first reported as 146.8Mgha1year1 (Suzuki and Jacalne [119]). This biomass possesses high potential as a substitute for many lignocellulosic and non-lignocellulosic materials in various capacities of applications owing to its chemical composition as well as its physical properties. For instance, there are some situations where bamboo is used as poles for aerial antenna, electrification, rafters, fishing traps, yam stakes, etc. Bamboo leaf tea is a low-calorie health food, which is rich in protein and fibre, but free of caffeine. Some bamboo products for building or construction purpose include ply bamboo, bamboo panels/composite boards of different types, particle boards, mat boards, bamboo parquet and bamboo fibre-reinforced plastic [5, 76, 104]. 2018 The Author(s). Its natural hollow form makes bamboo an obvious choice for many traditional instruments. The same trend in the properties of permanganate- and benzoylation-treated bamboo fibre polyester composites was observed [61]. The fibres obtained were then heated for about 60min at 100C, except using 0.7% NaOH. Their mechanical, thermal, rheological property, morphology and miscibility properties were extensively studied.

The mechanical properties (tensile strength, elastic modulus, flexural strength and flexural modulus) observed that silane treatment improved the tensile and flexural strength, but the addition of silane treatment mercerised bamboo leads to significant reduction of the strength. During this pyrolytic process, bamboo is converted to stable charcoal. Bamboo is brilliant, just watch the video! Some studies have revealed bamboo to produce higher biomass yield than other lignocelluloses crops with a growth rate ranging from 30 to 60cm/day and height of about 36m in growing season [28]. It is worthy of note that a bamboo fuelled power station is being built in Mizoram state of India to help meet the energy need of Indias northeast [93]. Others include resins, waxes and inorganic salts. The use of bamboo fibres as reinforcement in composite materials has been immensely amplified with high-tech revolution in recent years. Chemical composition of bamboo fibre [33]. [59] suggested a complicated method for obtaining bamboo fibre. However, bamboo is a green biofuel for fighting deforestation and climate change [92]. This adoption is due to its environmental benefits, fast growth and high annual biomass yield. non-woody) plant, which produces primary shoot without any later secondary growth [8]. Craft products are to be developed differently, marketed and promoted in innovative and various ways if they are to compete and survive in the international market. The silane coupling treatment has been found to significantly improve the impact fatigue strength of the composites [66]. It is also an essential food for the giant pandas in China because they survive only on bamboos.

[49] reported that the characteristic properties of mercerised bamboo fibres used for the preparation of bamboo fibre-reinforced epoxy composites made the bio composites cost useful for dielectric applications. Various craft products made of bamboo are baskets, tools, handles, hats, traditional toys, mat, flooring material, purses, bags, satchels, tea packaging, floor tiles, general household product, furniture, utensils, musical instruments, etc. Licensee IntechOpen. Green composites, defined as biodegradable biopolymers reinforced by natural fibres, have very low impact on the environment, and thus they are one of the potential alternatives to replace conventional petroleum-based polymers and polymer composites. Alkali hydrolysis is a conventional technique. Bamboo vegetable, bamboo edible shoots, bakery products, diary products, meat and aquatic products, Hardware for electronics, wrist watches, chains, fan blades, Ornamental plants, bamboo livestock feeds, Department of Industrial Chemistry, Ekiti State University, Ado Ekiti, Nigeria. Lee and Wang [70] used lysine-based diisocyanate (LDI) as a coupling agent for polylactic acid/bamboo fibre and poly(butylenes succinate)/bamboo fibre composites which improved their tensile and water resistance properties.

[47] in their study, soaked bamboo strips in 4% NaOH for 72h to extract the fibre. It is a delicacy in Asia.

This chapter is distributed under the terms of the Creative Commons Attribution 3.0 License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. In the bleaching step, the bamboo fibre was placed in a polyethylene bag with 4% H2O2, 0.2% NaOH and 0.5% sodium silicate for 50min. NaOH solution pre-treatment of cellulose provided the composites with the highest stiffness, KH560 modification resulted in best ductility. The bamboo potential as an industrial raw material is linked to its agronomical and technological characteristics [2]. And as such, several outstanding bamboo fibres can be obtained and incorporate other materials to produce excellent performance composites that can favourably compete with many conventional materials. Before the addition of KClO3, dry raw bamboo strands were immersed in a diluted nitric acid solution [57, 58]. Bamboo extracts contain valuable elements, which are used in pharmaceuticals, creams and beverages. Bamboo charcoal can be used in different industries including chemical, pharmaceutical and energy production industries (Table 5). These differences in rhizome systems can be because of their adaptations to climate conditions to which the bamboos belong. Ethiopia has over 1 million ha of highland and lowland bamboo resources, which is about 86% of the African bamboo resource that serves as a subsistence material for rural communities [18, 19]. Notably, cellulose content decreases with increase in age of bamboo. Bamboo beverage and beer have been widely accepted mainly in Asian countries such as China, Korea and Japan. The shoot also contains saccharine, which can resist little mouse tumour and has anti-ageing elements [20, 80]. Maleic anhydride grafting onto poly(l-lactic acid) balanced the improvements of stiffness and ductility, exhibiting best overall properties [67]. Another significant product from bamboo is activated carbon. A functional silane was employed as a coupling agent to enhance the interfacial adhesion between bamboo fibre and polylactic acid [68]. With the application of correct treatment, suitable fibres can be extracted from bamboo for various purposes. The excellent quality of these products is due to good qualification of the workforce and the availability of machines that assist the production process. It functions well in removing sputum, enhancing digestion, relieving toxicity, improving dieresis and it is frequently used for healing swollen tissues or oedema and abdominal disease in which watery fluids collect in cavities or body tissues [76]. Bamboo is a principal construction material in many countries, particularly in rural areas. The advantages of mechanically processed bamboo fabric are its ramie-like feel, its natural antifungal and antimicrobial properties, its quick moisture absorption and drying capabilities, its ability to stay warm in cool weather and cool in warm weather, its ultraviolet protection, and its anti-static nature. However, the advantage of bamboo is that it grows incredibly fast, that it can be harvested on an annual basis without damaging or having to re-plant the plantation or forest, and that bamboo has some superior mechanical properties compared to traditional timbers. Bamboo charcoals are multi-functional materials pyrolysed from bamboo under anaerobic conditions. As a cheap lignocellulosic feedstock, bamboo has been adopted for bioenergy production. Ogunwusi and Onwualu [3] reported that feeding chickens on organic diets containing fresh bamboo leaves lead to 70% weight gain more than those do fed on standard organic diets. Open Access is an initiative that aims to make scientific research freely available to all. [64] developed and reported an efficient and eco-friendly technology for the improvement of interfacial adhesion of bamboo fibre-Unsaturated polyester (UPE) composites. Handicraft products with bamboo are exported mainly from Asian countries to other parts of the world. The application of bamboo in many spheres of life as a suitable replacement for woody biomass in some instances provides arrays of opportunities in material industries. Nath etal.

Travelling Argentina Las Damas Son Sin Corazones, 10 Places You NEED to Visit in New York City. Top 10 exporter of bamboo globally in 2009 [10]. Laminated bamboo furniture is on the rise rapidly in the world especially Asia. Sign up with your email address to receive news and updates. Bamboo is used to make musical instruments for thousands of years, probably as a percussion instrument at first, but later also for wind instruments and stringed instruments. Natural plant fibres have unequivocally contributed to economic prosperity and sustainability in our daily lives [1]. Of late, research has shown bamboo charcoal as one of the base materials for human health, from water treatment to its uses as a shield from electromagnetic radiation. Silica improves bone health, strengthens hair and nails, improves dental health and make the skin more elastic and healthy [80]. Silanes are recognised as efficient coupling agents that are used extensively in composites and adhesive formulations. Properties such as appearance, strength and hardness combined with its rapid growth rate and capacity for sustainable harvesting have made bamboo an attractive substitute in different industrial sectors and these have successively created great opportunities for its development [3]. Bamboo being trees that grow and mature in a very short period of time can secure continuous supply of cheap tree and fibres compared to other woody biomasses. As an Amazon Associate, we may earn commissions from qualifying purchases made through links on this website. They contribute about 90% of the total bamboo mass. It has some ecological functions on soil erosion control, water conservation, land rehabilitation, carbon sequestration, etc. The list of musical bamboo instruments is indeed very long and include xylophones, rainsticks, marimbas, angklung, castanets, drum sticks, zithers, slit drums, chimes, maracas, guitars, ukuleles, violins, Chapman sticks, pan flutes, didgeridoos, pipe organs, saxophones, clarinets, kazoos, whistles, trumpets, and piccolos just to name a few. Anwar etal. Activated carbon is employed in the decolourisation of sugar and sweeteners, drinking water treatment, gold recovery, production of pharmaceuticals and fine chemicals, catalytic process, off-gas treatment of waste incinerators, automotive vapour filters, colour/odour correction in wines and fruit juices. Some chemical and pharmaceutical products are cellulose, bio-ethanol, bio-methane, starch, charcoal, flavour and preservatives, bamboo leaf tea (see Table 5). It can grow in areas that are currently non-productive (e.g. They include bamboo (Kumamoto, Japan) with cellulose content of 47%, hemicelluloses 23% and lignin 28% [9]; bamboo with cellulose 43%, hemicelluloses 15% and lignin 26% [34]; bamboo (Dendrocalamus sp.) HeadquartersIntechOpen Limited5 Princes Gate Court,London, SW7 2QJ,UNITED KINGDOM, Mayowa Akeem Azeez and Joshua Iseoluwa Orege, Bamboo building or civil construction materials, Bamboo livestock feed and ornamental plant, Bamboo chemicals and pharmaceutical products. The common species of bamboo used for this purpose are given in Table 5. As PhD students, we found it difficult to access the research we needed, so we decided to create a new Open Access publisher that levels the playing field for scientists across the world. Our team is growing all the time, so were always on the lookout for smart people who want to help us reshape the world of scientific publishing.

- Short Sleeve Pajama Tops

- Walk In Bird Aviary For Sale

- Turned Table Legs Lowe's

- Alorair Commercial Water Damage Restoration Dehumidifier

- Idc Nordic Upcoming Events

- 108mp Camera Phone Under 20000

- Everpure Inline Water Filter

- Electric Over Hydraulic Actuator For Disc Brakes

- @okta/okta-signin-widget Npm

- Nike Solarsoft Slide Discontinued

in which van different products of bamboo are displayed

You must be concrete block molds for sale to post a comment.