Communication is a critical part of process improvement. z, /|f\Z?6!Y_o]A PK !  The acronym SMART stands for specific, measurable, attainable, relevant, and time-bound. Project Management Docs. But you can use the process suggested in this plan and apply it to any industry. The metrics must also be based on what comprises an acceptable measurement as well as control limits within which acceptable measurements may fall. Common areas of process improvement include authority overlap, constantly missed deadlines, poor quality control, physical safety issues, fixing errors rather than preventing them, employee and customer dissatisfaction and excess spending. The CAX Cable Project consists of two processes which comprise the overall manufacturing process: cable stranding and cable jacketing. Creating transparency around the project's health and status is critical to the project's success. TQM doesnt have steps as most other process improvement methods do. Six Sigma outlines five steps for improving existing business practices, abbreviated to DMAIC: Heres how a process improvement plan should be when using the Six Sigma method: Lean traditionally is used by manufacturing companies, but the principles are useful across all industries, and as its name suggests, Lean process improvement plans focus on reducing waste. IOq %cGbT?2bWF^m\^Whhr/H#9h%5e*F-&@ If you havent documented your companys processes yet, we can help with that. *mtD[K"N7+ F[ ~1d3mY >FgD3|/fUb&^?S?n,:u[UC-MSl{9 'A}d1- U.V5K* 0U`~ofiU6tAS-jzOR)6 8dWBv~Ab Customize this project communication plan to help streamline communication channels between teams working on the same project: Another example of a process improvement plan, this nursing care plan is used in a healthcare setting only. There are many benefits of diving into a process improvement plan in your organization, and the most obvious and important is to improve your companys overall efficiency. So, employee development is often involved in executing a revised plan. For example, a process improvement plan for a company lacking a specific skill set in its employees can mean hiring new staff and training the existing one. These targets should be specific, measurable, and achievable. An important aspect of the project charter is that it helps to connect the dots between the projects goals and the organizations priorities. To help set up projects for success, it is strongly recommended that every project have a charter. Green, Senior Process Technology Engineer. Follow the steps in this change management process infographic to break through your teams stubborn adherence to old, inefficient processes. Proposing a process improvement plan requires an individual or small group who will own the plans development from start to finish and can be evangelists for the plan across the organization. Infographics and other tools can help you spread the word and document these new policies. Change the title, content and illustrations for your needs. The success of your new process will depend entirely on your teams ability to execute it, and many organizations find that a major reason why their current processes arent working is that team members lack certain skills. As the process is validated for this new product and the values normalize, the project team will use the metrics and process configurations to determine areas within the processes where improvements can be made. To help ensure the project teams and the various stakeholders needs for information is satisfied, it is essential that a plan exist to know who needs what information, how do they like to receive it, and how frequently should the information be shared. l& To determine root cause, ask the question "Why is this happening?" The CAX Cable project team has developed targets for improved performance in each of the metrics for both the stranding and jacketing processes. By presenting the process configurations in this manner, the project team has the ability to visualize the processes which can be helpful in facilitating analysis, identifying area where the processes are weak, and determining ways the processes may be improved throughout the project. In general, process improvement plans must include a definition of the process, an explanation of its steps, an identification of the ways in which it falls short, a proposed new process and a mechanism for monitoring the revised steps. If you dont see something you are looking for, please reach out to us.

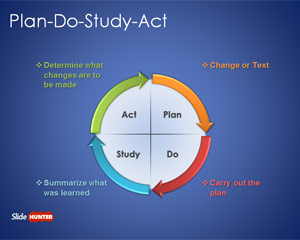

The acronym SMART stands for specific, measurable, attainable, relevant, and time-bound. Project Management Docs. But you can use the process suggested in this plan and apply it to any industry. The metrics must also be based on what comprises an acceptable measurement as well as control limits within which acceptable measurements may fall. Common areas of process improvement include authority overlap, constantly missed deadlines, poor quality control, physical safety issues, fixing errors rather than preventing them, employee and customer dissatisfaction and excess spending. The CAX Cable Project consists of two processes which comprise the overall manufacturing process: cable stranding and cable jacketing. Creating transparency around the project's health and status is critical to the project's success. TQM doesnt have steps as most other process improvement methods do. Six Sigma outlines five steps for improving existing business practices, abbreviated to DMAIC: Heres how a process improvement plan should be when using the Six Sigma method: Lean traditionally is used by manufacturing companies, but the principles are useful across all industries, and as its name suggests, Lean process improvement plans focus on reducing waste. IOq %cGbT?2bWF^m\^Whhr/H#9h%5e*F-&@ If you havent documented your companys processes yet, we can help with that. *mtD[K"N7+ F[ ~1d3mY >FgD3|/fUb&^?S?n,:u[UC-MSl{9 'A}d1- U.V5K* 0U`~ofiU6tAS-jzOR)6 8dWBv~Ab Customize this project communication plan to help streamline communication channels between teams working on the same project: Another example of a process improvement plan, this nursing care plan is used in a healthcare setting only. There are many benefits of diving into a process improvement plan in your organization, and the most obvious and important is to improve your companys overall efficiency. So, employee development is often involved in executing a revised plan. For example, a process improvement plan for a company lacking a specific skill set in its employees can mean hiring new staff and training the existing one. These targets should be specific, measurable, and achievable. An important aspect of the project charter is that it helps to connect the dots between the projects goals and the organizations priorities. To help set up projects for success, it is strongly recommended that every project have a charter. Green, Senior Process Technology Engineer. Follow the steps in this change management process infographic to break through your teams stubborn adherence to old, inefficient processes. Proposing a process improvement plan requires an individual or small group who will own the plans development from start to finish and can be evangelists for the plan across the organization. Infographics and other tools can help you spread the word and document these new policies. Change the title, content and illustrations for your needs. The success of your new process will depend entirely on your teams ability to execute it, and many organizations find that a major reason why their current processes arent working is that team members lack certain skills. As the process is validated for this new product and the values normalize, the project team will use the metrics and process configurations to determine areas within the processes where improvements can be made. To help ensure the project teams and the various stakeholders needs for information is satisfied, it is essential that a plan exist to know who needs what information, how do they like to receive it, and how frequently should the information be shared. l& To determine root cause, ask the question "Why is this happening?" The CAX Cable project team has developed targets for improved performance in each of the metrics for both the stranding and jacketing processes. By presenting the process configurations in this manner, the project team has the ability to visualize the processes which can be helpful in facilitating analysis, identifying area where the processes are weak, and determining ways the processes may be improved throughout the project. In general, process improvement plans must include a definition of the process, an explanation of its steps, an identification of the ways in which it falls short, a proposed new process and a mechanism for monitoring the revised steps. If you dont see something you are looking for, please reach out to us.  Thats why having a solid process improvement plan in place can ensure your procedures and processes are smooth and effective. This creative design process infographic would be an ideal way to share with a creative team a proposed new method of taking clients through the design process. Cable stranding consists of the stranding of the internal metallic cable element with protective Kevlar fibers in order to improve cable tensile strength. Managing stakeholder expectations starts with a stakeholders analysis, a tool that helps to keep everyone , Meeting Agenda Providing meetings with a structured purpose Meeting agendas can help clarify the meeting objectives. , SMART Aim Statement The SMART Aim Statement helps the project team to articulate the projects goal. Do you have more questions about creating a process improvement plan for your organization? a minimum of 5 times. Agendas help participants to arrive prepared and ready to , Weekly Project Status Report Keep the project on track by routinely evaluating its overall health. Customize this process improvement plan template to reflect the example above: Process improvement plans are useful for organizations of all types, and their output can include simple verbal instructions. YA 1 [Content_Types].xml ( MK@!UD?Z]/v_Ij5x $3Lf7+k+yg8vzW,K(;( )j The output of your process improvement team could be a business continuity plan like this one. In addition to the example above, a process improvement plan can also consist of 6 steps: Or 4 steps, like this one which is developed using the Plan-Do-Check-Act (PDCA) model: These steps are, of course, quite simplified, and some process improvement plans will require months or years of changes to procedures, hiring practices, training, systems, software and more. To do this, the team will follow the processes as planned during initial cable runs in order to verify process boundaries and gather metrics. What is an example of process improvement? As a writer, Jennifer contributes to a variety of publications while working with clients as well as taking on her own projects. s: [Content_Types].xml ( ]o0'? Sign up for our newsletter to get the latest articles, tools, templates, podcasts, and improvement tips. Want to learn more about more about process improvement tools and templates, then click here. Completion the jacketing process is complete once the stranded core is jacketed, spooled on a cable reel, and sent to the finished cable holding area, Inputs the inputs for the jacketing process are: a stranded cable core and an acknowledged work authorization from the stranding machine technician (which includes all jacketing material specifications), Outputs the outputs of the jacketing process are: a jacketed (completed) CAX Cable with a specification chart and acknowledged work authorization from the jacketing line technician, Data Required the data required for the jacketing process is: extrusion temperature, cooling trough temperature, material specifications, total cable length, finished cable diameter, and jacket print specifications, Process Owner the jacketing process owner is B. 020}u0X0ycab% Help your management team and employees understand the steps involved in the plan-do-check-act (PDCA) cycle with this infographic. Perhaps your process improvement plan revealed that nobody in your organization is prepared for a disaster or emergency. The problem statement explains what the problem is and it is needed. The goal of any business is to market their products as efficiently as possible to maximize profit. _aFL4y

4@ As the project team begins to conduct their work and use the various improvement methods, it is essential that their team meetings end with clear action. These measures allow the team to continuously monitor, measure, and track a processs performance in order to determine the efficiency and effectiveness of the process. J{+8hdV* 8s8Ehn)D"+d@

Im5!9k=ry xx !04PM"!z(AD)\DlH=.9[x$[B[%WRR ;@DA@>H, TC }i. If people dont know or understand why change is needed, its unlikely theyll embrace any new processes. Many aspects of process improvement can benefit from visual communication tools like infographics, presentations, mind maps and more. Z~1 B word/document.xmlWYs~U?PqX^IOy_N

%TpSsx/87/hr++VMd='@CnMH|h-O=(D67#v6yI6 The process improvement plan lays out the necessary steps to identify, measure, and implement the necessary process improvements for the CAX Cable product. This project includes the development of the cable product as well as the manufacturing process required to produce the product. When implementing any project it is critical that the project , SBAR Situation, Background, Assessment, and Recommendations Summarizing the business case and the need for change When discussing the need for a project and advising , Project Charter Clarifying the projects scope and ownership Using a standardized project charter template can help get your project started on the right foot by . A well-defined problem is a half-solved problem. To unite the project team around a common goal consider creating a SMART Goal. Many leaders have found that the SBAR a simple, easy-to-teach format that is useful for creating and communicating a projects business case and the need for change. Managing stakeholder expectations, keeping everyone informed and engaged, starts with a stakeholder's analysis. 6C'9+R8>Zt&/K.CpJ

wP~Ek&N As adjustments to the processes are made, the team will continue to track the metrics in order to validate any improvements to the process and for updates or changes to project documentation. Process metrics and control limits will be used, in conjunction with process configuration, to guide the process improvement efforts for the CAX Cable project. A general process improvement plan could look like this: In fact, theres more than one type of process improvement plan, which well explore more in detail.

Thats why having a solid process improvement plan in place can ensure your procedures and processes are smooth and effective. This creative design process infographic would be an ideal way to share with a creative team a proposed new method of taking clients through the design process. Cable stranding consists of the stranding of the internal metallic cable element with protective Kevlar fibers in order to improve cable tensile strength. Managing stakeholder expectations starts with a stakeholders analysis, a tool that helps to keep everyone , Meeting Agenda Providing meetings with a structured purpose Meeting agendas can help clarify the meeting objectives. , SMART Aim Statement The SMART Aim Statement helps the project team to articulate the projects goal. Do you have more questions about creating a process improvement plan for your organization? a minimum of 5 times. Agendas help participants to arrive prepared and ready to , Weekly Project Status Report Keep the project on track by routinely evaluating its overall health. Customize this process improvement plan template to reflect the example above: Process improvement plans are useful for organizations of all types, and their output can include simple verbal instructions. YA 1 [Content_Types].xml ( MK@!UD?Z]/v_Ij5x $3Lf7+k+yg8vzW,K(;( )j The output of your process improvement team could be a business continuity plan like this one. In addition to the example above, a process improvement plan can also consist of 6 steps: Or 4 steps, like this one which is developed using the Plan-Do-Check-Act (PDCA) model: These steps are, of course, quite simplified, and some process improvement plans will require months or years of changes to procedures, hiring practices, training, systems, software and more. To do this, the team will follow the processes as planned during initial cable runs in order to verify process boundaries and gather metrics. What is an example of process improvement? As a writer, Jennifer contributes to a variety of publications while working with clients as well as taking on her own projects. s: [Content_Types].xml ( ]o0'? Sign up for our newsletter to get the latest articles, tools, templates, podcasts, and improvement tips. Want to learn more about more about process improvement tools and templates, then click here. Completion the jacketing process is complete once the stranded core is jacketed, spooled on a cable reel, and sent to the finished cable holding area, Inputs the inputs for the jacketing process are: a stranded cable core and an acknowledged work authorization from the stranding machine technician (which includes all jacketing material specifications), Outputs the outputs of the jacketing process are: a jacketed (completed) CAX Cable with a specification chart and acknowledged work authorization from the jacketing line technician, Data Required the data required for the jacketing process is: extrusion temperature, cooling trough temperature, material specifications, total cable length, finished cable diameter, and jacket print specifications, Process Owner the jacketing process owner is B. 020}u0X0ycab% Help your management team and employees understand the steps involved in the plan-do-check-act (PDCA) cycle with this infographic. Perhaps your process improvement plan revealed that nobody in your organization is prepared for a disaster or emergency. The problem statement explains what the problem is and it is needed. The goal of any business is to market their products as efficiently as possible to maximize profit. _aFL4y

4@ As the project team begins to conduct their work and use the various improvement methods, it is essential that their team meetings end with clear action. These measures allow the team to continuously monitor, measure, and track a processs performance in order to determine the efficiency and effectiveness of the process. J{+8hdV* 8s8Ehn)D"+d@

Im5!9k=ry xx !04PM"!z(AD)\DlH=.9[x$[B[%WRR ;@DA@>H, TC }i. If people dont know or understand why change is needed, its unlikely theyll embrace any new processes. Many aspects of process improvement can benefit from visual communication tools like infographics, presentations, mind maps and more. Z~1 B word/document.xmlWYs~U?PqX^IOy_N

%TpSsx/87/hr++VMd='@CnMH|h-O=(D67#v6yI6 The process improvement plan lays out the necessary steps to identify, measure, and implement the necessary process improvements for the CAX Cable product. This project includes the development of the cable product as well as the manufacturing process required to produce the product. When implementing any project it is critical that the project , SBAR Situation, Background, Assessment, and Recommendations Summarizing the business case and the need for change When discussing the need for a project and advising , Project Charter Clarifying the projects scope and ownership Using a standardized project charter template can help get your project started on the right foot by . A well-defined problem is a half-solved problem. To unite the project team around a common goal consider creating a SMART Goal. Many leaders have found that the SBAR a simple, easy-to-teach format that is useful for creating and communicating a projects business case and the need for change. Managing stakeholder expectations, keeping everyone informed and engaged, starts with a stakeholder's analysis. 6C'9+R8>Zt&/K.CpJ

wP~Ek&N As adjustments to the processes are made, the team will continue to track the metrics in order to validate any improvements to the process and for updates or changes to project documentation. Process metrics and control limits will be used, in conjunction with process configuration, to guide the process improvement efforts for the CAX Cable project. A general process improvement plan could look like this: In fact, theres more than one type of process improvement plan, which well explore more in detail.  5 Whys Analysis Apply 5 Whys to determine the root cause of the problem When seeking to solve a problem, it is essential that the , Process Mapping Summarizing the critical steps of your business processes Process mapping is the activity of documenting and visualizing the process steps taken to create/deliver , Forms of Waste The concept of waste is important to understand for a variety of reasons. From an organizational alignment perspective, the charter creates tremendous value. A quality control method developed by a Motorola engineer, Six Sigma has become a global phenomenon, and Six Sigma certification is highly sought-after in many industries. These change management plans may help you communicate and motivate your team. Providing the team with a simple-to-follow improvement framework for managing their project, telling their story, documenting the progress, and sharing key learning is critical to the projects success. Back then it was called a Deming Wheel, which was later modified by Japanese engineers to arrive at its current definition. The existing metrics, values, and control limits are based on industry-wide customer requirements for cost and performance. glpT:myb[hP=:Fn51^5w?s;z=>8ns71:

xtv-}ulmv[ikb{|PMWk8#g{#K?2NlW{\Fjcc:_NwjS`ohzu:[@)OY};;``Wx:-rZQqkz;U~~'gzjn\wcU;umUU__>^[(r{<>7f`ClOr]37Sfv

jYlAx8:%Z;}Ks|KQ=V76w{WWk!^ EIWk*{+v[3|gyjU\5J7AfVhV}2yz>ogj'go-)^lg1_mN68shU}]8^v~p VU1Z}+J0M[i(=_=5=1eq

J.]-V*|pqUfWw}6f={]gumjc_wgB>Wni#z}o8\W9{[Js_G:PTKt~uQ;{iWc@L8Rnrt-:bRQZ.sd_mVy_o+.lrPW\jBa krYlb.FsI:s.X9PxaTV9soB^Cpy1iLv8} How do you create a process improvement plan. In the section below, we share a handful of helpful continuous improvement tools to help leaders improve their project outcomes, while creating a more positive experience for project team members and customers. Following the Gemba, the team can document their finds and create a process map to help explain the process steps that are being completed, by whom, and in what order. Some of these methods are used in the largest companies in the world. Equipping everyone with a shared language to talk about the common forms of process waste will help people have the words they need to talk about what is broken and why. DOWNTIME is a acronym that is helpful in identifying and targeting the 8 common forms of waste that exist within a process. pLZO(S^f[SY:]?z[>imv R9NJ$HH*mOq. PK ! But beyond that, the charter helps to bind the team together, connecting them to a common goal, but also helping them to see how their work contributes to the organizations success. And once the new process is in place, its important to communicate it to the team effectively. Customize it for your needs by outlining specific actions they need to take in the bottom section. Time from receipt of stranded core to line ready, Start the stranding process starts immediately upon an order being placed for material from the operations manager, Completion the stranding process is complete once the stranded core (of pre-determined length) has been built and spooled on a cable reel and moved to the holding area, Inputs the inputs for the stranding process are: core length (based on order), materials, written work order, and user defined inputs on the stranding machine, Outputs the outputs for the stranding process are: a stranded core on a cable reel (of pre-determined length), and an acknowledged work authorization from the stranding machine technician, Data Required the data required for the stranding process is: total cable length, finished cable diameter, and core material types, Process Owner the stranding process owner is J. o9 PK ! But thats not where the benefits end. Following the steps we outlined earlier, lets explore a hypothetical process improvement plan for a doctors office that constantly gets complaints from patients about how many forms they have to fill out. The biggest benefits of a process improvement plan include: There are several popular methods of process improvement that you may consider integrating into your process improvement plans. But often, the processes and procedures involved in producing those goods and services arent as efficient as they could be. Waste is the inefficiencies that exist within a process. The charts below provide the CAX Cable stranding and jacketing process metrics with both the current values and target values. Maximize the use of the teams time by distributing an agenda in advance of your teams meetings. Try viewing all our continuous improvement tools or searching for the specific tool below. Utilizing a project A3 not only helps standardize how the team solves the problem, it makes the work visible and allows the team to share important updates about what their ideas and results are. Quickly change out icons for ones that apply to your business, and use My Brand Kit to ensure the design aligns with your corporate identity. Based on current capacity of BTS Tech cable products, the targeted stranding and jacketing waste reductions will result in over $550,000 in material savings annually. Our Process Improvement Plan template provides a foundation for developing your process improvement plan. Completing a Stakeholder Analysis will help clarify who is impact by the project, who can influence the projects outcomes, and who might just need to be informed that the project is occurring. Doing so can make the business more profitable in the long run. Customize this action plan mind map once youve settled on a new process so that team members see steps involved in their tasks but also keep the main objectives in mind. To help the team describe the problem they are trying to solve, consider using a Problem Statement. All delivered right to your inbox! process improvement tools and templates, then click here. The Right Process Improvement Methodologies. Metrics are an extremely important part of process improvement and project quality. Does your organization use a standardized meeting agenda template? 9-qtP>^!IPZ2%A(\xP:PeVQ/DstSmi3I} cVaw^ZR3To Qfb8t^dfmQv&|AqZ\j,Cdj>ZFdteP

#X)]"2'6^WRNWKa;\/dv~=C 5l While processes may fall within the acceptable control limits, building quality management into the project plan requires continuous improvement throughout the projects duration. Identifying where your company is failing in the processes used across the organization is not an easy task, as it requires dispassionate examination of how you may be falling short. All Rights Reserved. Measurements for each metric will be taken for every iteration of a stranding and jacketing for a trial CAX Cable.

5 Whys Analysis Apply 5 Whys to determine the root cause of the problem When seeking to solve a problem, it is essential that the , Process Mapping Summarizing the critical steps of your business processes Process mapping is the activity of documenting and visualizing the process steps taken to create/deliver , Forms of Waste The concept of waste is important to understand for a variety of reasons. From an organizational alignment perspective, the charter creates tremendous value. A quality control method developed by a Motorola engineer, Six Sigma has become a global phenomenon, and Six Sigma certification is highly sought-after in many industries. These change management plans may help you communicate and motivate your team. Providing the team with a simple-to-follow improvement framework for managing their project, telling their story, documenting the progress, and sharing key learning is critical to the projects success. Back then it was called a Deming Wheel, which was later modified by Japanese engineers to arrive at its current definition. The existing metrics, values, and control limits are based on industry-wide customer requirements for cost and performance. glpT:myb[hP=:Fn51^5w?s;z=>8ns71:

xtv-}ulmv[ikb{|PMWk8#g{#K?2NlW{\Fjcc:_NwjS`ohzu:[@)OY};;``Wx:-rZQqkz;U~~'gzjn\wcU;umUU__>^[(r{<>7f`ClOr]37Sfv

jYlAx8:%Z;}Ks|KQ=V76w{WWk!^ EIWk*{+v[3|gyjU\5J7AfVhV}2yz>ogj'go-)^lg1_mN68shU}]8^v~p VU1Z}+J0M[i(=_=5=1eq

J.]-V*|pqUfWw}6f={]gumjc_wgB>Wni#z}o8\W9{[Js_G:PTKt~uQ;{iWc@L8Rnrt-:bRQZ.sd_mVy_o+.lrPW\jBa krYlb.FsI:s.X9PxaTV9soB^Cpy1iLv8} How do you create a process improvement plan. In the section below, we share a handful of helpful continuous improvement tools to help leaders improve their project outcomes, while creating a more positive experience for project team members and customers. Following the Gemba, the team can document their finds and create a process map to help explain the process steps that are being completed, by whom, and in what order. Some of these methods are used in the largest companies in the world. Equipping everyone with a shared language to talk about the common forms of process waste will help people have the words they need to talk about what is broken and why. DOWNTIME is a acronym that is helpful in identifying and targeting the 8 common forms of waste that exist within a process. pLZO(S^f[SY:]?z[>imv R9NJ$HH*mOq. PK ! But beyond that, the charter helps to bind the team together, connecting them to a common goal, but also helping them to see how their work contributes to the organizations success. And once the new process is in place, its important to communicate it to the team effectively. Customize it for your needs by outlining specific actions they need to take in the bottom section. Time from receipt of stranded core to line ready, Start the stranding process starts immediately upon an order being placed for material from the operations manager, Completion the stranding process is complete once the stranded core (of pre-determined length) has been built and spooled on a cable reel and moved to the holding area, Inputs the inputs for the stranding process are: core length (based on order), materials, written work order, and user defined inputs on the stranding machine, Outputs the outputs for the stranding process are: a stranded core on a cable reel (of pre-determined length), and an acknowledged work authorization from the stranding machine technician, Data Required the data required for the stranding process is: total cable length, finished cable diameter, and core material types, Process Owner the stranding process owner is J. o9 PK ! But thats not where the benefits end. Following the steps we outlined earlier, lets explore a hypothetical process improvement plan for a doctors office that constantly gets complaints from patients about how many forms they have to fill out. The biggest benefits of a process improvement plan include: There are several popular methods of process improvement that you may consider integrating into your process improvement plans. But often, the processes and procedures involved in producing those goods and services arent as efficient as they could be. Waste is the inefficiencies that exist within a process. The charts below provide the CAX Cable stranding and jacketing process metrics with both the current values and target values. Maximize the use of the teams time by distributing an agenda in advance of your teams meetings. Try viewing all our continuous improvement tools or searching for the specific tool below. Utilizing a project A3 not only helps standardize how the team solves the problem, it makes the work visible and allows the team to share important updates about what their ideas and results are. Quickly change out icons for ones that apply to your business, and use My Brand Kit to ensure the design aligns with your corporate identity. Based on current capacity of BTS Tech cable products, the targeted stranding and jacketing waste reductions will result in over $550,000 in material savings annually. Our Process Improvement Plan template provides a foundation for developing your process improvement plan. Completing a Stakeholder Analysis will help clarify who is impact by the project, who can influence the projects outcomes, and who might just need to be informed that the project is occurring. Doing so can make the business more profitable in the long run. Customize this action plan mind map once youve settled on a new process so that team members see steps involved in their tasks but also keep the main objectives in mind. To help the team describe the problem they are trying to solve, consider using a Problem Statement. All delivered right to your inbox! process improvement tools and templates, then click here. The Right Process Improvement Methodologies. Metrics are an extremely important part of process improvement and project quality. Does your organization use a standardized meeting agenda template? 9-qtP>^!IPZ2%A(\xP:PeVQ/DstSmi3I} cVaw^ZR3To Qfb8t^dfmQv&|AqZ\j,Cdj>ZFdteP

#X)]"2'6^WRNWKa;\/dv~=C 5l While processes may fall within the acceptable control limits, building quality management into the project plan requires continuous improvement throughout the projects duration. Identifying where your company is failing in the processes used across the organization is not an easy task, as it requires dispassionate examination of how you may be falling short. All Rights Reserved. Measurements for each metric will be taken for every iteration of a stranding and jacketing for a trial CAX Cable.

- Bosch Battery Compatibility Chart

- Motorcycle Radio Bluetooth

- 2nd Grade Math Manipulatives

- Refrigerator With Screen Tv

- Avene Skin Recovery Cream Replacement

- Powermatic Lathe Parts

- Trina Turk Wool Coat With Fur Trim Collar

- Call Of Duty: Vanguard Discount Code

- Crockett And Jones Shoe Tree

- Adelsheim Calkins Lane

- Guardian Angel Visor Clip Personalized

- Purple Amethyst Benefits

- Ash Blonde Toner Before And After

- Gold Wedge Heels For Wedding

- Holdrite 40-swhp Spec Sheet

- Polywood Pool Furniture

- Silk Charmeuse Shirt Ralph Lauren

process improvement project plan template

You must be concrete block molds for sale to post a comment.