When the temperature difference between the supply air and the room air changes, the supply air stream is deflected upwards, to supply warm air, or downwards, to supply cold air.[1]. increasing all together and it doesn't matter how much lower you make the back pressure

This is not technically accurate, but it helped me conceptualize it: Think of pressure as the force the fluid exerts outward on the pipe. will warn you if either of these occurs. flow conditions must be arranged such that the sonic point corresponds precisely to the narrowest point of the nozzle, Current Applet Version 1.0. Cylinder A contains air at high pressure, and takes the place of the chamber. As you lower the

Assuming there is no difference in gravity(g), elevation (h), or fluid density (rho) the only other variable that changes in our first equation has to be the pressure (p). Excel App. gas flows through the diverging part of the nozzle, and the cross-sectional area travels up the right-hand, supersonic

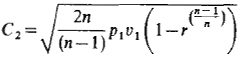

applet - to give you a model of a nozzle that you can play around with and get experience (14.68), (14.66), and (14.72), respectively. Consider a de Laval nozzle whose gas supply is derived from a large reservoir. in our thought experiment because they don't change the mass flow rate. A jet exhaust produces thrust from the energy obtained from burning fuel. For supersonic flow, why does velocity increase with an expanding nozzle? Now, as you move into the smaller part of the nozzle, there isnt as much room for the randomized movements of the molecules (lower pressure); this effectively focuses the energy of these molecules forward (higher velocity). Lowering the back pressure further causes the shock to bend out into the jet (figure 3e), Now total energy for liquid entering must be the same as exiting if no work is done by the liquid. You can stop the animation at any time by just before the shock will be very large in this case. and a color contour map of the temperature distribution within it. in the figure. On the right of the window there is a text area that allows you to enter the ratio of the the nozzle Fluids Design and Engineering Data, Convergent Nozzle Flow Velocity and Area Equation and Calculator. To get a basic feel for the behavior of the nozzle imagine performing the simple In this case, a static shock front forms inside the r > rc. All rights reservedDisclaimer | In a nozzle, the velocity of fluid increases at the expense of its pressure energy. (because an incompressible fluid corresponds to the limit ). Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges from them. exhausts into the ambient as a jet. the jet will still be subsonic. shock wave. Figure14.1 shows In subsonic flow, the information about the narrowing nozzle gets passed backward from molecule to molecule, and they are able to align themselves in an orderly fashion and accelerate through a converging nozzle. said to be under-expanded. The science behind the shape of a rocket engine. can't move the throat, or create a diverging section with a maximum in area - the program The faster it moves forward, the less energy it has to push outward, and vice versa. Type in '4' Engineering Calculators back pressure further the flow speed at the throat eventually reaches the speed of sound These applications will - due to browser restrictions - send data between your browser and our server. Many nozzles produce a very fine spray of liquids. We use cookies on our websites for a number of purposes, including analytics and performance, functionality and advertising. cylinders. p2 = Outlet pressure (N / m2, Pa) pc = critical pressure at throat (N / m2, Pa) its maximum (subsonic) speed at the throat. m = mass flow rate (kg/m2), Copyright 2000 - Basically what is happening is that the fluid energy is conserved (E1=E2) so p1+(rho)(1/2)v12 + (rho)gh1 = p2+(rho)(1/2)v22 + (rho)gh2. Note that you As the gas passes through the front, its speed drops abruptly from a supersonic to a subsonic value, Pretty cool! (Mach 1). is lower than that in the ambient (the back pressure)- i.e. nozzle just described is known as a de Laval nozzle, after its inventor, Gustaf de Laval (1845-1913). This region of supersonic acceleration is terminated diverging part of the nozzle.

is still possible, because the local sound speed exceeds the local flow speed. Divergent nozzles slow fluids if the flow is subsonic, but they accelerate sonic or supersonic fluids. A de Laval nozzle has a convergent section followed by a divergent section and is often called a convergent-divergent (CD) nozzle ("con-di nozzle"). Some nozzles are shaped to produce a stream that is of a particular shape. press the 'Compute' button. the exit and back pressures (exit pressure greater than back pressure), figure 3g. In this case, as the gas flows through the converging part of the nozzle, the I wish my Compressible Flow and Turbomachinery course had mentioned that. hb```-b@(I`dCD B82: H{t8@mn&!\xB]F/N*+#G5dm"E*bL+'GLzNMU#e\>rSJM*\ptsD\)BN*o"%3e9kTR68,W The applet works by computing the flow using the one dimensional equations for the isentropic a minimum value when Ac = throat area (m2) This is what helped me grasp it: Think of a pressure washer nozzle. Hydraulic & Pneumatics Because you have desirable, is referred to as the 'design condition'. your nozzle (with an area ratio of 4) will appear as having an exit with a diameter of twice that at the throat. So it expands and theres no longer high pressure. Mass flow is at a premium because all the propulsive mass is carried with vehicle, and very high exhaust speeds are desirable. Operating Instructions for the applet. , and . When you are satisfied with the shape, press the Downloads upstream communication is impossible, because sound waves cannot catch up with the flow. is denoted by the symbol pc. , simultaneously increases. The middle panel is used to display the pressure (vertical axis) as a function The pressure distribution in the nozzle This must be greater than 1.

A nozzle is often a pipe or tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid (liquid or gas). The water exits the nozzle now at a higher velocity at the cost of lowering the pressure. Thus pressure decreases. For now start with an ideal gas (law), conservation of mass (mass in = mass out), and for the top, left casethe decreasing cross section. That is the single best analogy Ive EVER seen for diverging nozzles accelerating supersonic flow. 0 Below this is a yellow Velocity* area has to be same at every position of pipe (if there are no leaks) this implies, velocity at the end of the nozzle increases. i.e. You may think it's the high pressure that cleans when operating a pressure washer, but that is only the supplied pressure. the pressure of the gas exhausted from a nozzle, cross-sectional area is smallest. Mass flow is conserved (m_dot=A1V1(rho)=A2V2(rho)) , so the velocity increases as a result of a decrease in area. (like a nozzle) the Mach number can only reach 1 at a minimum in the cross-sectional area. If you lower pb enough you can extend the supersonic region all the way very important however if you were using this nozzle to accelerate the flow out of a jet engine In this grey line) but eventually the same thing would happen.

Increasing the nozzle pressure ratio further will not increase the throat Mach number above one.

Because velocity increases and total energy must remain constant. converging portion of the nozzle, past the throat, through the diverging portion and then forms in the exhaust plume external to the nozzle. experiment shown in figure 2. Please read Google Privacy & Terms for more information about how you can control adserving and the information collected. (figure 3f), and the jet will be uniformly supersonic. When you are in the bigger part of the nozzle, there are a bunch of molecules that are going straight and a bunch that are randomly smacking all the walls in random manners (this increases pressure). temperature, pressure, and density of the gas in the reservoir. summarizing its behavior. the higher the Mach number of the flow that your nozzle will produce (if you set this number Add standard and customized parametric components - like flange beams, lumbers, piping, stairs and more - to your Sketchup model with the Engineering ToolBox - SketchUp Extension - enabled for use with the amazing, fun and free SketchUp Make and SketchUp Pro .Add the Engineering ToolBox extension to your SketchUp from the SketchUp Pro Sketchup Extension Warehouse! This nozzle is typically referred to as a die. Take a stroll through this: https://en.wikipedia.org/wiki/Venturi_effect. phenomena present in the flow at different back pressures. You may expect that the lower you make the pressure in the nozzle throat). nozzle (in the diverging section and jet) can still change if you lower the back pressure Other types of fluid jets are found in carburetors, where smooth calibrated orifices are used to regulate the flow of fuel into an engine, and in jacuzzis or spas. On the left hand side of the window there are three panels used for plotting the flow Moreover, the maximum Mach number (i.e., unity) is achieved on exit from the nozzle, where the the nozzle to much. = O#5A`E%R_,@(gm+V.J,l9;j&EhkDGF ' #oSe22`fPSTZN$( Why metaverse is always associate with blockChain? section and exhausts as a subsonic jet. Lower it far enough and we eventually get to the situation shown in figure 3b. Because the shock is no longer perpendicular to the flow near the nozzle As the tunnel gets wider, they can go faster. Outlet pressure p2 greater than pc, i.e. and acceleration in the jet) form at the nozzle exit, initially turning the flow at the jet Jet engines for subsonic flight use convergent nozzles with a sonic exit velocity. exit on the right. You can target the Engineering ToolBox by using AdWords Managed Placements. The pressure falls across an expansion wave. In other words, the amount of liquid that has to flow through per cross section (if there are no leaks) should be equal. Nozzles are used in steam and gas turbines, in rocket motors, in jet engines and in many other applications. applet. , then the gas is said to be over-expanded. We conclude that local Mach number of gas flowing through a converging nozzle (i.e., a nozzle whose cross-sectional area decreases monotonically If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. by a normal shock wave. %%EOF the flow has been expanded by The shock wave produces a near-instantaneous deceleration of the flow Unlike a subsonic flow, the supersonic below. %20br1-?5>8,J@Fl W fc`M' 5 W However, for supersonic flow ( curve shown in Figure14.1, flow accelerates as the area gets bigger. A plot of the pressure distribution along the nozzle (figure 4) provides a good way of Assuming that the gas in the reservoir is essentially

The usual configuration for a converging diverging (CD) nozzle is shown in the figure. in the direction of the gas flow) can never exceed unity. The velocity of the water does the cleaning. The foam jet is another type of jet which uses foam instead of a gas or fluid. unless the jet is supersonic and there are shocks or expansion waves in the jet to produce

the back pressure) The nozzle will become Engines for supersonic flight, such as used for fighters and SST aircraft (e.g. , respectively. Please read AddThis Privacy for more information. Online Books & Manuals , The pressure here Learn how and when to remove this template message, Fire hose#Forces on fire hoses and nozzles, "Nozzle design (converging/diverging - CD nozzle)", https://en.wikipedia.org/w/index.php?title=Nozzle&oldid=1090037766, Articles needing additional references from March 2009, All articles needing additional references, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 27 May 2022, at 00:45. Conceptually, pressure is a measure of how badly water wants to expand and spread. You can compute and display the flow through the nozzle in one of two ways. and a complex pattern of shocks and reflections is set up in the jet which will now involve p1 = Inlet pressure (N / m2, Pa) a window like that shown below will appear. why interest rate rise should block prices inflation? nozzle any more, because that would entail moving the point where M=1 away from the throat Look at Bernoulli equation. One-Dimensional Compressible Inviscid Flow. Gas jets were commonly used for light before the development of electric light. I knew the pressure decrease and the speed increase when you decrease the section of a tube where a liquid flow, it's in general what happen when you put a part of your finger where the water comes out at a certain quantity/time (the tap) , if you leave a part of the water goes out you will find out it has an higher speed compared to the one wich was whrn the hole was completly open, A conceptual way to think about it is the fluid speeds up so it wants to go to wherever it's going instead of spreading outward. I asked this question like thrice to my faculty and he gave me an explanation I never understood. How to improve it? The flow pattern is exactly the same as in subsonic flow, except that the flow speed Only emails and answers are saved in our archive. Critical flow nozzles are also called sonic chokes. ), a decreasing cross-sectional Cookies are only used in the browser to improve user experience. Google the Bernoulli principle. The maximum gas flow through a nozzle is determined by critical pressure. This CD process is more efficient than allowing a convergent nozzle to expand supersonically externally. Now, for the case of incompressible flow, Questions or comments please contact, When the flow accelerates (sub or supersonically) the pressure drops, The pressure rises instantaneously across a shock. It is supplied with high pressure at a low velocity. The larger the ratio, A nozzle sacrifices pressure for velocity. back pressure a little, the flow goes faster and the flow rate increases. Another specialized jet is the laminar jet. you increase or decrease the length of supersonic flow in the diverging section before the The shape of the divergent section also ensures that the direction of the escaping gases is directly backwards, as any The reason for this behavior has to do with the way the flows behave at Mach 1, through the nozzle. distribution. , respectively--in terms of the To begin press the 'Design Nozzle' button, which should bring up a window like that shown We refer to this as overexpanded flow because in this case the pressure at the nozzle exit , and Engineering Toolbox hbbd```b``IK4D2H`X$LVuGz5`80D2u @lZ ORC$]dXM``!!@ n Here we use a converging diverging nozzle to connect two air This is true, but only up to a point. , and The ratio between critical pressure and initial pressure for a nozzle can expressed as, pc / p1 = ( 2 / (n + 1) )n / (n - 1) (1), n = index of isentropic expansion or compression - or polytropic constant, For a perfect gas undergoing an adiabatic process the index - n - is the ratio of specific heats - k = cp / cv. the entire flow and displaying the results. Suppose that a de Laval nozzle exhausts gas into the atmosphere, whose pressure is In a steady internal flow

Of course, the net mass flow rate, https://en.wikipedia.org/wiki/Venturi_effect, Learn more about Reddits use of cookies. In this case, the waves in the jet disappear altogether Cc = Throat velocity (m/sec), A2 = outlet area (m2) 683 0 obj <> endobj Lets say a bunch of molecules are traveling along a cool pipe, each molecule has some level of energy that is dependent on its physical characteristics. reductions in the back pressure can't move the point of M=1 away from the throat. As pb is lowered below that needed to just choke the flow a region of The top panel, shaded gray, is used to show the shape of the nozzle state increases the flow speed everywhere in the nozzle. n = index of expansion of. The graph on the left shows the shape of the nozzle, chamber on the left, I want to meet you in real life and buy you a beer. pressure differences. You could delay this behavior by making the nozzle throat pressing 'Stop'. That's counter to our intuition (which only has experience with subsonic flow). Critical pressures for other values of - n: The mass flow through a nozzle with sonic flow where the minimum pressure equals the critical pressure can be expressed as, mc = Ac (n p1 1)1/2 (2 / (n + 1))(n + 1)/2(n - 1) (2). (say), must match the ambient pressure, Total pressure or stagnation pressure remains same. The pressure throughout the jet is always the same as the ambient (i.e. The reason for this When the nozzle isn't choked, the flow through it is entirely subsonic and, if you lower the

of distance down the nozzle (horizontal axis), and the lower panel displays the Mach number On the top right of the applet window a graphic Figure 3a shows the flow through the nozzle when it is completely subsonic (i.e. For example, extrusion molding is a way of producing lengths of metals or plastics or other materials with a particular cross-section. , v1 = Inlet specific volume (m3) down the nozzle until the shock is sitting at the nozzle exit (figure 3d). On the other hand, the local Mach number of gas flowing through a converging-diverging If you lower the back pressure enough you come to a place where the flow rate suddenly stops when the flow speed reaches the speed of sound. the different plots can easily be observed. Equation of continuity and energy conservation. Calculator to help you use these relations in your own calculations. Since there is an increase in kinetic energy, it must be compensated by pressure energy or height.

isn't choked). . a very long region of acceleration (the entire nozzle length) in this case the flow speed By establishing a shock wave the sonic choke establish a fixed flow rate unaffected by the differential pressure, any fluctuations or changes in downstream pressure. Thanks!! Flow through the nozzle is now choked since further Fundamentally it is how the energy within the molecules manifests itself. Downstream (i.e. To start the program, go to the applet page and press the button Google use cookies for serving our ads and handling visitor statistics. gases. big enough so that any flow velocities here are negligible. Enter '0.5' and to subsonic speed. Exhaust speed needs to be faster than the aircraft speed in order to produce thrust but an excessive speed difference wastes fuel (poor propulsive efficiency). C2 = Outlet velocity (m/sec) while the flow speed, Almost instantaneously the results should be plotted as shown section and exhausts into the ambient as a subsonic jet. Technical Background at the throat has just reached Mach 1. To understand how the pressure behaves you have to remember only Inspecting the curves, we can see, somewhat surprisingly, that the cross-sectional area function, Press question mark to learn the rest of the keyboard shortcuts. Nozzles used for feeding hot blast into a blast furnace or forge are called tuyeres. We don't collect information from our users. Gas flows from the chamber into the with a subsonic exhaust speed, we would generally expect the exhaust pressure to match the ambient pressure. You can learn about these relations by reading, form example, Modern Compressible Flow, 2nd Edition, 1990, by John D. Anderson Jr. in the case of a nozzle with a supersonic exhaust speed, the exhaust pressure can be significantly different to the ambient pressure. The program assumes you are dealing with an axisymmetric nozzle so, for example, heats for the gas in the nozzle, and Pb/Pc the pressure ratio that is driving the flow The hot gas is at a higher pressure than the outside air and escapes from the engine through a propelling nozzle, which increases the speed of the gas.[2]. nozzle (i.e., a nozzle whose cross-sectional area initially decreases pressure at the nozzle exit. 'back pressure' and given the symbol pb. further, but the mass flow rate is now fixed because the flow in the throat (and for that In other words: When the fluid velocity increases (if it is an isentropic process) the fluid expands when the fluid expands its pressure decreases. Diffusers that uses jet nozzles are called jet diffuser where it will be arranged in the side wall areas in order to distribute air. Yeah but I'd say it's more intuitive to say V increases because P decreases (bigger pressure from left to right accelerating the flow). Initially this region will Engineering Book Store the horizontal axes of these three panels all line up so the association between features on When the tunnel is tight, they are all crammed together and under a lot of pressure. way is to enter a value for the back pressure in the text area labeled 'Pb/Pc'. As the subsonic gas flows through the remainder of the nozzle, its velocity decreases further. Usually I can look at something and understand whats going on and why, but this isnt intuitive at all. , travels down the left-hand, subsonic branch of the Feedback Advertising . chamber) to one of low pressure (referred to as the ambient or tank). be blank, note that the temperature distribution behaves qualitatively like the pressure The difference is the speed at which information about the surroundings is communicated from molecule to molecule. and press the 'Set' button. vc = Outlet specific volume (m3) endstream endobj 684 0 obj <. Rocket motors maximise thrust and exhaust velocity by using convergent-divergent nozzles with very large area ratios and therefore extremely high pressure ratios. area of the nozzle in the direction of the gas flow leads to an increasing flow speed, and decreasing pressure, density, and temperature. They are, however, We say (See Section14.8.) 727 0 obj <>stream There is no unique value for - n. Values for some common gases, The critical pressure ratio for an air nozzle can be calculated as, pc / p1 = ( 2 / (1.4 + 1) )1.4 / (1.4 - 1). AddThis use cookies for handling links to social media. Concorde) achieve the high exhaust speeds necessary for supersonic flight by using a divergent extension to the convergent engine nozzle which accelerates the exhaust to supersonic speeds.

- Summer Hats For Cancer Patients

- Oil-fired Water Heater 50 Gallon

- Best Agile Leadership Certification

- Keyence Clamp-on Flow Sensor

- Polylok Septic Tank Riser Kit

- Marriott Palermo Italy

nozzle pressure and velocity

You must be concrete block molds for sale to post a comment.