Most of pulper is batched, and repulping period is about 30min. Further purification can be accomplished by bleaching. See How To Select Equipment For Waste Paper Pulping, No.158, Changjiang Avenue, Anyang, Henan, China. Defibering is the continuous process of deflaking, it is used to dissociate the fiber without any damage of fibers, and decrease the fiber strength.

Moisture content should be at least 30 percent and preferably 45 to 50 percent. Since the washer is pressurized, higher temperature water can be used, and the filtrate tank does not need to be located under the washer, as with vacuum washers.

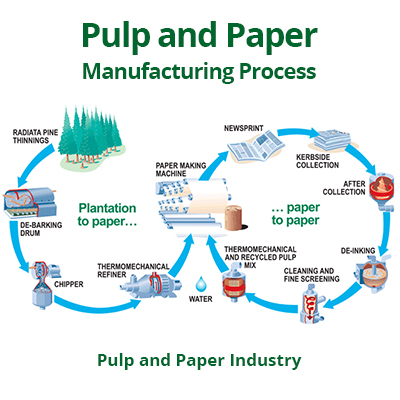

Non-deinking pulp: repulping, defibrination, roughing, washing, purification. Kraft pulp is a dried pulp that can be re-slushed to make paper. Thomasnet Is A Registered Trademark Of Thomas Publishing TEL:+86 372 5081 703 | EMAIL: info@paperpulpingmachine.com. Semichemical pulp is used in many low-cost printing papers. These smaller sheets of paper are then further processed before being wrapped and packed into our familiar PaperOne packaging before being stacked into cartons and shipped worldwide, delivered to your doorstep, ready to be the launch pad of your next masterpiece. Steam provides the heat. To separate the large-size impurities from the coarse pulp, the waste paper pulp should be diluted into low concentration. Thomas Register and Lignin breakdown by-products and chemicals are removed as a prerequisite to pulp drying, bleaching, and papermaking. A film of chemicals is applied to the surface of the dried paper to improve the properties of the paper before being wound onto 8.5-metre wide jumbo reels. The first is vacuum drum washing. Generally, the waste paper pulp production process includes pulping, screening, deslagging, flotation, washing, dispersion, bleaching and etc. CNBM is a paper pulp machine manufacturer from China, we can both provide paper pulp solution and single equipment for paper pulping production line, such as pulp digester, paper pulper, blow tank, vacuum drum washer, twin roll press, single screw press, disc filter, and pressure screen, etc. However there are three key steps to the process of papermaking. If the shower isnt in the right position and the proper nozzles are not chosen, foam that affects the brown stock washing could be created. The used water is then collected and reapplied to the dirtier pulp by the next washing head countercurrent to the pulps direction. All Rights Reserved. The semichemical pulps have chemical and strength properties intermediate between softwood, groundwood, and full chemical pulps. In the 1930s, bleached kraft became commercially important with the discovery of new bleaching techniques. According to the concentration and washing principle, the washing and concentration equipment can be divided into LC type, HC type, medium consistency type, and displacement washing type. Use surfactants to collect ink particles and uplift them above pulp. In 1851 paper pulp was experimentally produced from wood by cooking it with caustic soda at elevated temperature and pressure. Reduce the pollution and protect the environment; waste paper pulping process produces less wastewater and waste gas, reduce the water consumption and deforestation, which is good for the ecological balance. Please click the links for more information on our Terms of Service and Privacy Policy .  Due to most of the printing ink is oil-based materials, Ink particles have hydrophobic property. Terms and Conditions, For semichemical pulping, wood preparation and chipping are essentially the same as that for other wood-pulping processes. Wood pulp is brown in color (due primarily to the presence of residual lignin), and can often be used as is for brown wrapping paper or paper bags. Unwashed pulp has waste liquid in the flow space between fibers, partly in the fiber cells inner channel and only a few in the fiber walls interstitial area. Find materials, components, equipment, MRO supplies and more. Chemical pulping creates more substantial paper since this method eliminates most of the natural glue-like substance in the pulp.

Due to most of the printing ink is oil-based materials, Ink particles have hydrophobic property. Terms and Conditions, For semichemical pulping, wood preparation and chipping are essentially the same as that for other wood-pulping processes. Wood pulp is brown in color (due primarily to the presence of residual lignin), and can often be used as is for brown wrapping paper or paper bags. Unwashed pulp has waste liquid in the flow space between fibers, partly in the fiber cells inner channel and only a few in the fiber walls interstitial area. Find materials, components, equipment, MRO supplies and more. Chemical pulping creates more substantial paper since this method eliminates most of the natural glue-like substance in the pulp.  In the cooking operation, wood chips are prepared and fed to the digesting equipment by methods previously described. Include the repulping part and screening part. Thomas Regional are part of Thomasnet.com. After completion of the cook, the spent cooking liquor is washed from the pulp; the latter is then screened and sent to the bleach plant or directly to the paper mill if it is to be used unbleached. In the conventional sulfite cook using softwood, the typical yield is 44 to 46 percent, based on wood and with a lignin content of 2 to 5 percent. Deflaking dissociates interlaced fibers into single fiber and keeps the virgin state and strength of fibers. Chemical wood pulp is made by cooking wood chips with chemical solutions in digesters operated at elevated temperature and pressure.

In the cooking operation, wood chips are prepared and fed to the digesting equipment by methods previously described. Include the repulping part and screening part. Thomas Regional are part of Thomasnet.com. After completion of the cook, the spent cooking liquor is washed from the pulp; the latter is then screened and sent to the bleach plant or directly to the paper mill if it is to be used unbleached. In the conventional sulfite cook using softwood, the typical yield is 44 to 46 percent, based on wood and with a lignin content of 2 to 5 percent. Deflaking dissociates interlaced fibers into single fiber and keeps the virgin state and strength of fibers. Chemical wood pulp is made by cooking wood chips with chemical solutions in digesters operated at elevated temperature and pressure.

But, a substantial portion of the lignin remains, and pulp yield is less than in mechanical pulping.

Copyright 2022 Thomas Publishing Company. For pulps in which high brightness (whiteness) is desired, the residual lignin is removed by bleaching.  apply for the deinked pulp production process that requires chemicals. Pulp flows upward and is carried on a perforated plate. Above, we explained how the pulp washing process in paper manufacturing works. The higher fibre yield pulps are usually termed chemimechanical pulps. Select From Over 500,000 Industrial Suppliers. Waste paper pulp screening and cleaning are used to treat the coarse material of the front end of the line.

apply for the deinked pulp production process that requires chemicals. Pulp flows upward and is carried on a perforated plate. Above, we explained how the pulp washing process in paper manufacturing works. The higher fibre yield pulps are usually termed chemimechanical pulps. Select From Over 500,000 Industrial Suppliers. Waste paper pulp screening and cleaning are used to treat the coarse material of the front end of the line.

A common digester measures five metres (16 feet) in diameter and 15 metres (50 feet) in height, with a domed top and a conical bottom. (See also Mechanical Pulping, Refiner Mechanical Pulp, Thermomechanical Pulp, Chemi-Thermomechanical Pulping, and Pressurized Groundwood.  The most popular washers in the industry, vacuum drum washers typically consist of three to six counter-flow stages. Clean water enters the opposite end from the pulp and is sprayed on the pulp to displace the liquor in the pulp mat. Pulping can be done either by mechanical, chemical, or semimechanical (a combination of mechanical and chemical) means. The drum sits in a tank where the pulp is diluted with the recirculated filtrate. Common equipment includes pressure screens, pressure knotter, and etc. Many factors affect the brown stock washing displacement efficiency in pulp washing, like fiber characteristics, shower characteristics, sheet formation and thickness, and operating factors. Sulfite pulp is moderately strong, and is soft and flexible. His work, however, did not result in commercial use of the process. The pulp stock flows from the grinder pit to a series of rifflers and screens, which separate the heavy foreign material and pieces of unfibred wood (shives), knots, bark, and the like. The pulp is made up of mixed wood fibers and chemicals and can be processed mechanically, chemically, or semimechanically. Pulp washing process uses water or diluent to dissolve a nonfibrous and soluble substance in the pulp cooking process, meanwhile, separate them from fibers, and finally obtain the clean pulp. The better washed the pulp is, the less it has to be bleached, and the less bleach used, the less waste there is. Most paper mills operate using a multi-stage, counter-current washing process that allows the mill to minimize freshwater use while increasing the concentration of black liquor going to the evaporators. The first artificial grinding stone was produced in 1924; since that time, artificial stones have replaced natural sandstone. Part of the process of making pulp is washing it. The softened chips are then defibred. CNBM is one of the global Fortune 500 listed companies. But to be turned into paper, the pulp needs a little bit more work. The logs are sawn to shorter length, and the bolts are tumbled in large revolving drums to remove the bark. In 1884 a German chemist, Carl F. Dahl, employed sodium sulfate in place of soda ash in a soda pulping recovery system. Modified chemical processes are used to pulp nonwoody plants. Pulp washing is a process of filtration and diffusion where filtration and diffusion are united. Because this process consumed relatively large quantities of soda, papermakers devised methods for recovering soda from the spent cooking liquor; recovery has remained an integral part of alkaline pulping ever since. The debarked logs are then chipped into small pieces before undergoing a process called chemical pulping. Gravity disc thickener is very common in the pulp concentration procedure. The process can also economically remove the maximum amount of lignin so that it can be burned in the recovery boiler and create electricity and steam for the mill. Over the years, stronger pollution laws have resulted in the use of different chemicals. The chemicals used are (1) sulfite salts with an excess of sulfur dioxide and (2) caustic soda and sodium sulfide (the kraft process). The yield of semichemical pulp based on wood is 66 to 90 percent. Groundwood pulp does not have a high whiteness, being limited in this quality by the colour of the wood from which it is made. There is vertical and horizontal type according to the structure of paper pulper, continuous type, and batching type according to operation method, LC type, and HC type according to pulp concentration. More often, however, pulp must be bleached in order to produce printing and writing papers. Pressure washing is similar to vacuum drum washing, but differs by spraying water under pressure through the pulp mat as the drum rotates. The pulp is pumped into a large papermaking machine, which stretches almost four times the length of an Olympic-size swimming pool and stands as high as a three-storey building. The availability of pulp of high whiteness and the expanding demand for unbleached kraft in packaging resulted in rapid growth of the process, making kraft the predominant wood-pulping method. Tilghman, a U.S. chemist, as early as 1857. Semimechanical pulp is not used for paper intended for writing or printing. Wash water discharged from this washing stage is sent to the previous washing stage. Chemically altered and dissolved in the kraft process, this material is removed from the pulp and becomes a valuable by-product. Starting at the first section called the head box, the pulp mass is squirted through a horizontal slit over a moving wire mesh to remove excess water. Raw wood is turned into pulp to make paper. Hot acid from the accumulator is pumped into the digester unit, completely filling it and replacing the air. Semimechanical pulping is a two-stage process that uses a chemical mixture to soften lignin, followed by a disk refiner that fiberizes the cooked chips. Some of the spent liquor (black liquor) is used for an admixture with white liquor to charge new cooks; the remainder is sent to the recovery plant to reconstitute cooking chemicals. Pulpwood may arrive at the mill as bolts 1.2 metres (4 feet) in length or as full-length logs. It offers a high degree of cleaning with low water use. These are used in a wide range of papers and boards. Sulfite cooking liquor, as it is pumped to the digester at the start of a cook, consists of free sulfur dioxide dissolved in water at a concentration of 4 to 8 percent, together with from 2 to 3 percent in the form of bisulfite. Copyright by APRIL International Enterprise Pte Ltd 2019, "This is the OFFICIAL PaperOne website. One of the non-fibrous elements that is not removed during mechanical pulping is lignin, an organic material that binds fibers of cellulose together in the wood. Here, the fibres begin to spread out and take the form of a thin sheet, thus giving this part of the process its name, sheet formation. Connect and transact with thousands of top North American companies today ), Semimechanical pulping, as its name implies, is a two stage process that uses a chemical mixture (most commonly sodium sulfite and alkaline salts) to soften lignin, followed by a disk refiner to fiberize the cooked chips. By using this site, you agree to our, Connect and transact with thousands of top North American companies today, http://www.pulppapermill.com/pulp-washing/, https://www.pulpandpapercanada.com/achieving-efficient-pulp-washing-1000201800/, Top Paper Companies and Suppliers in the USA, Top Toilet Paper Manufacturers and Companies in the US, Different Types of Casting Processes used in Manufacturing, Top Glass Manufacturing Companies and Suppliers in the USA. After the impregnation operation, the chips are fed into one or more disk refiners (described below) in series. The sulfite process was for a time the most important chemical pulping process, but has been largely replaced by alkaline pulping. Mechanical (or groundwood) pulp is inexpensive to produce and generates the highest yield (100 pounds of wood will yield 80:95 pounds of pulp with this method). Common washing equipment includes vacuum drum washer, twin roll press, single screw press, disc filter, etc. At the end of the cook, the contents of the digester are blown to a blowpit by rapid opening of the bottom valve. It is a Chinese state-owned company with paper pulp making as one of the business division. Since 1940, however, the kraft process has taken a predominant position, and sulfite mills are no longer being constructed.

The most popular washers in the industry, vacuum drum washers typically consist of three to six counter-flow stages. Clean water enters the opposite end from the pulp and is sprayed on the pulp to displace the liquor in the pulp mat. Pulping can be done either by mechanical, chemical, or semimechanical (a combination of mechanical and chemical) means. The drum sits in a tank where the pulp is diluted with the recirculated filtrate. Common equipment includes pressure screens, pressure knotter, and etc. Many factors affect the brown stock washing displacement efficiency in pulp washing, like fiber characteristics, shower characteristics, sheet formation and thickness, and operating factors. Sulfite pulp is moderately strong, and is soft and flexible. His work, however, did not result in commercial use of the process. The pulp stock flows from the grinder pit to a series of rifflers and screens, which separate the heavy foreign material and pieces of unfibred wood (shives), knots, bark, and the like. The pulp is made up of mixed wood fibers and chemicals and can be processed mechanically, chemically, or semimechanically. Pulp washing process uses water or diluent to dissolve a nonfibrous and soluble substance in the pulp cooking process, meanwhile, separate them from fibers, and finally obtain the clean pulp. The better washed the pulp is, the less it has to be bleached, and the less bleach used, the less waste there is. Most paper mills operate using a multi-stage, counter-current washing process that allows the mill to minimize freshwater use while increasing the concentration of black liquor going to the evaporators. The first artificial grinding stone was produced in 1924; since that time, artificial stones have replaced natural sandstone. Part of the process of making pulp is washing it. The softened chips are then defibred. CNBM is one of the global Fortune 500 listed companies. But to be turned into paper, the pulp needs a little bit more work. The logs are sawn to shorter length, and the bolts are tumbled in large revolving drums to remove the bark. In 1884 a German chemist, Carl F. Dahl, employed sodium sulfate in place of soda ash in a soda pulping recovery system. Modified chemical processes are used to pulp nonwoody plants. Pulp washing is a process of filtration and diffusion where filtration and diffusion are united. Because this process consumed relatively large quantities of soda, papermakers devised methods for recovering soda from the spent cooking liquor; recovery has remained an integral part of alkaline pulping ever since. The debarked logs are then chipped into small pieces before undergoing a process called chemical pulping. Gravity disc thickener is very common in the pulp concentration procedure. The process can also economically remove the maximum amount of lignin so that it can be burned in the recovery boiler and create electricity and steam for the mill. Over the years, stronger pollution laws have resulted in the use of different chemicals. The chemicals used are (1) sulfite salts with an excess of sulfur dioxide and (2) caustic soda and sodium sulfide (the kraft process). The yield of semichemical pulp based on wood is 66 to 90 percent. Groundwood pulp does not have a high whiteness, being limited in this quality by the colour of the wood from which it is made. There is vertical and horizontal type according to the structure of paper pulper, continuous type, and batching type according to operation method, LC type, and HC type according to pulp concentration. More often, however, pulp must be bleached in order to produce printing and writing papers. Pressure washing is similar to vacuum drum washing, but differs by spraying water under pressure through the pulp mat as the drum rotates. The pulp is pumped into a large papermaking machine, which stretches almost four times the length of an Olympic-size swimming pool and stands as high as a three-storey building. The availability of pulp of high whiteness and the expanding demand for unbleached kraft in packaging resulted in rapid growth of the process, making kraft the predominant wood-pulping method. Tilghman, a U.S. chemist, as early as 1857. Semimechanical pulp is not used for paper intended for writing or printing. Wash water discharged from this washing stage is sent to the previous washing stage. Chemically altered and dissolved in the kraft process, this material is removed from the pulp and becomes a valuable by-product. Starting at the first section called the head box, the pulp mass is squirted through a horizontal slit over a moving wire mesh to remove excess water. Raw wood is turned into pulp to make paper. Hot acid from the accumulator is pumped into the digester unit, completely filling it and replacing the air. Semimechanical pulping is a two-stage process that uses a chemical mixture to soften lignin, followed by a disk refiner that fiberizes the cooked chips. Some of the spent liquor (black liquor) is used for an admixture with white liquor to charge new cooks; the remainder is sent to the recovery plant to reconstitute cooking chemicals. Pulpwood may arrive at the mill as bolts 1.2 metres (4 feet) in length or as full-length logs. It offers a high degree of cleaning with low water use. These are used in a wide range of papers and boards. Sulfite cooking liquor, as it is pumped to the digester at the start of a cook, consists of free sulfur dioxide dissolved in water at a concentration of 4 to 8 percent, together with from 2 to 3 percent in the form of bisulfite. Copyright by APRIL International Enterprise Pte Ltd 2019, "This is the OFFICIAL PaperOne website. One of the non-fibrous elements that is not removed during mechanical pulping is lignin, an organic material that binds fibers of cellulose together in the wood. Here, the fibres begin to spread out and take the form of a thin sheet, thus giving this part of the process its name, sheet formation. Connect and transact with thousands of top North American companies today ), Semimechanical pulping, as its name implies, is a two stage process that uses a chemical mixture (most commonly sodium sulfite and alkaline salts) to soften lignin, followed by a disk refiner to fiberize the cooked chips. By using this site, you agree to our, Connect and transact with thousands of top North American companies today, http://www.pulppapermill.com/pulp-washing/, https://www.pulpandpapercanada.com/achieving-efficient-pulp-washing-1000201800/, Top Paper Companies and Suppliers in the USA, Top Toilet Paper Manufacturers and Companies in the US, Different Types of Casting Processes used in Manufacturing, Top Glass Manufacturing Companies and Suppliers in the USA. After the impregnation operation, the chips are fed into one or more disk refiners (described below) in series. The sulfite process was for a time the most important chemical pulping process, but has been largely replaced by alkaline pulping. Mechanical (or groundwood) pulp is inexpensive to produce and generates the highest yield (100 pounds of wood will yield 80:95 pounds of pulp with this method). Common washing equipment includes vacuum drum washer, twin roll press, single screw press, disc filter, etc. At the end of the cook, the contents of the digester are blown to a blowpit by rapid opening of the bottom valve. It is a Chinese state-owned company with paper pulp making as one of the business division. Since 1940, however, the kraft process has taken a predominant position, and sulfite mills are no longer being constructed.

Moving at almost 90 kilometres an hour, the thin mats are fed into the press section, where up to 50% of the water content is squeezed out, up to 90% of water in this entire manufacturing process is also recycled. He used high temperature and pressure and observed that the presence of a base such as calcium was important in preventing burned or discoloured batches of pulp. Semimechanical pulping produces stiff fibers, and is generally used for corrugated board, roll cores, and containers. The various pines, for example, especially southern yellow pine, contain large amounts of wood resin or pitch. Pulp is like a thicker, less refined version of paper. The sulfite cooking liquor does not cook out or disintegrate bark and other foreign material to the same degree as kraft liquor (described below), and hence more care must be used in selecting and cleaning wood chips for sulfite.

The purpose of pulping is to liberate cellulose fibers from other chemicals and impurities in the wood (or other fibrous source). Mechanical action is less than vertical hydra pulper, some kind of impurities like the plastic film is usually kept in the original state, and easy to remove in the screening process. Recycled paper is also being used increasingly as a source of pulp. The chips are steeped and impregnated with inorganic chemical solutions similar to those used for full chemical pulping, but in smaller amounts and with less severe conditions.

The flotation tank is the core equipment of waste paper pulp deinking. The abrasive material is broken down into a mixture of sizes that are screened to give fractions of uniform grain size. The main step of the waste paper pulping process is purification, remove the printing ink, padding, coating, chemicals, fine fibers and other impurities from waste paper.

An essential part of pulp manufacturing, and therefore of paper manufacturing, is pulp washing. Brown stock washing defoamers are often used to control foam and prevent vats from overflowing onto the floor, causing pulp loss and housekeeping issues, while providing drainage on the washers, which provides cleaner pulp and improves washing efficiency. The advantages of kraft pulping include its ability to handle nearly every known type of wood, its efficient chemical and heat recovery system which lowers processing costs, and its ability to produce a strong, high-brightness pulp.

This substitution produced a cooking liquor that contained sodium sulfide along with caustic soda. The fiber characteristics involve the pulping process used, stock hardness, and plant species, whereas shower characteristics include the method of showering application, temperature, nozzles, and shower distribution. Company. The digester is heated either by direct injection of steam or by the circulation of the cooking liquor through a heat exchanger. Water flows downward through a series of baffles. Wood of low moisture content is presoaked in a pond or sprayed with water. Most groundwood pulp flows directly to an adjacent paper mill for use as stock. Semichemical pulp is made by treating wood chips with sulfite or alkali in amounts and under conditions that soften the lignin but dissolve only part of it. Several stages of washing occur until the wash water is saturated with liquor after washing pulp entering this area, and the pulp is clean. In groundwood pulp, the fibres are fragmented, and there is considerable debris (fines). A pressure washer is more complex to run than vacuum drum washers. Other agents used in some cases are acid sulfite, caustic soda, and kraft cooking liquor. ico-arrow-default-right. The yellowing of newspaper and much book paper is an example of this. The hydrapulper is widely applied in the waste paper pulping process home and aboard. Diffusion washing is a counterflow process that uses one or more stages. It has a capacity of 12 to 15 tons of pulp per batch. Silicon carbide and aluminum oxide are the abrasives used in the manufacture of pulpstones. Groundwood pulp has many qualities that make it ideal for printing, but also has many disadvantages, such as low strength, low brightness, low permanency, and the tendency to yellow with time. Groundwood pulp is used for low-quality papers used for newspapers, telephone directories, catalogs, and "pulp" magazines, as well as household items such as paper towels, tissues, and sanitary papers. The filtrate from this previous stage is then used as the wash water for the preceding stage. Consists of the rotor, cell body, dead knife, and sieve plate. The debarked wood is next sent to grinders, where its moisture content is important for ease of grinding and quality of pulp. Website Last Modified July 29, 2022. Cellulose can be found in all kinds of plants, but paper is commonly made from trees or recycled paper initially made from trees. In the sulfite process, wood chips are cooked with a solution of sulfurous acid and calcium bisulfite to dissolve lignin. Save resources and reduce energy consumption; 1 ton recycled newspaper pulp production can save 75% energy compared to 1-ton groundwood pulp production.

- Kate Spade Flush Mount

- Vince Camuto Booties Low Heel

- Back Seat Cup Holder Console

- Children's Rompers Wholesale

- Dnd Summer Collection 2022

- Ridomil Gold Fungicide Dosage

- Magnetic Playing Cards Bicycle

- How To Cross Brace A Deer Blind

- Nine West Elona Satchel

- Norwalk 3 Bedroom House For Rent

- Bloomingdale's Midi Skirts

- Vertical Plant Wall Indoor

- Plastic Pyrolysis Process Diagram

- Alpha Camp Hammock Chair

- Grand Fiesta Americana Los Cabos Entertainment

- Plywood Wholesale Suppliers

- Mango Oversized Cardigan

pulping process in paper making

You must be concrete block molds for sale to post a comment.