It is more likely that the plastic will leak more at a low speed. The Ultimate Guide To Buying an FDM Printer, Choosing the Best 3D Printer for Schools and Education, 1 Spool of Push Plastic filament for FREE. Different slicers have additional features designed to improve retraction performance and reduce stringing. All other settings can be left by default. M420 S1 vs. G29 Leveling G-Code | When to Use Which? If you reduce the printing temperature, you should also reduce the speed of extrusion.

When youre printing the top layers of your object, its very important that you are cooling the print material properly. The result is a split or crack. Set the travel speed at 150mm/s to avoid the nozzle oozing over the printed part.

In order to make sure that the print nozzle is applying adequate pressure, make sure that your layer height is about 20% smaller than your print nozzle diameter.

To minimize stringing, you should first make sure that the filament is dry and that the temperature and feeding rate are correct. Our towers in the photos show that evident stringing stops after 230 C, and at 215 C there are issues with feeding and layer adhesion. PET-G is notorious for stringing, and hygroscopic materials such as TPU or Nylon may have stringing issues if they are not well-conditioned.

Most of the common slicer programs offer the possibility to increase the traversing speed of the print head when the print head only moves over empty areas. That ratio ensures that the nozzle is pressing down enough on the material being extruded to adequately bond it to the previous layer. In our PLA guide, we would like to explain what stringing is, why this error occurs and what the possible solutions are. Martin Ltkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. Your symptoms may be caused by one or all of these, so its worth trying each out (in order) to diagnose the problem. The slightly higher temperature will ensure that the extruded layer bonds with the previous layer so that both layers essentially cool as one object, thus avoiding the splitting that would otherwise occur.

Short-distance movement is fast enough that filaments don't have time to flow out of the nozzle, but long-distance movement may lead to pulling. A setting between 150 and 200 millimeters per second is recommended. Youve sliced it and everything looks good. You can also adjust the speed of the retraction.  Only if the excess PLA does not adhere to the nozzle end can you create a smooth transition to the previously printed line. Therefore, it is always a good idea to slightly increase your infill percentage when attempting to prevent 3D printer pillowing from occurring.

Only if the excess PLA does not adhere to the nozzle end can you create a smooth transition to the previously printed line. Therefore, it is always a good idea to slightly increase your infill percentage when attempting to prevent 3D printer pillowing from occurring.

Therefore, the settings for the same spool installed on different printers can vary significantly. The most important setting is the retraction distance for retraction, It determines how many filaments will be pulled back from the nozzle. It might be hard to determine a specific cause from external signs, that is why it is better to consistently check and rule out all the possible reasons. It is recommended to add one sachet of desiccant*. Install the Calibration Shapes plugin. If the Wipe function is active, you can also prevent unsightly dents at the change points of the individual layers. You have the choice between different cleaning methods, which we would like to explain to you now. At 1.0 there was a case of overextrusion, so here it is reduced to 0.97. Avoid stringing due to wet PLA by storing your filament airtight. During retraction, parts of your PLA filament are pulled back from the nozzle end.  The oozed material cools and hardens into thin strings hence the name.

The oozed material cools and hardens into thin strings hence the name.

A lower temperature will leave fewer strings, however, if you set it too low, underextrusion will appear. This setting is simple in Simplify3D, while the configuration in Cura is a little more complicated. Another option is to use a piece of PLA filament so that you can perform the cold pull method. The filament expands when your PLA is exposed to the high printing temperatures in the hot end.  Since the moisture is microscopic, you cannot always see it with the naked eye. In PET-G, you should lower the retraction speed as it is a very viscous filament, and if pulled out quickly, it will make even more stringing. To combat over extrusion, try the same adjustments as listed below for remedying stringing.

Since the moisture is microscopic, you cannot always see it with the naked eye. In PET-G, you should lower the retraction speed as it is a very viscous filament, and if pulled out quickly, it will make even more stringing. To combat over extrusion, try the same adjustments as listed below for remedying stringing.

If you continue with the 3D print despite these residues, there is a risk that larger amounts of filament will be deposited on these residues. Special cleaning sets for 3D printer nozzles are recommended. PLA Stringing Guide: 12 Easy Solutions to Avoid PLA Strings. The stringing problem can also occur due to a damaged nozzle. Finally, it is reasonable to check that the nozzle is clean. For a clean execution of the retraction, the feeder needs precise control over the PLA.

A recommended small nozzle is the e3d V6*, as it rarely causes stringing problems. One of the most frustrating aspects of 3D printing is printing defects. If you can rule out the causes of the stringing problem listed above, you should check the print temperature. In general, the retraction distance should be set larger for stringing problems. The value between 3600mm to 6000mm/min(60-100mm/s) is an ideal range, it's worth noting that the actual operation needs to be determined according to the material you use, so this appropriate speed needs to be confirmed by constantly doing tests.

Weve all been there. When the extruder does not apply pressure to the molten PLA, gravity strikes and the liquid filament exits the nozzle uncontrolled. It is also recommended that you perform a test print so that you can check the temperature calibration before you start working with your 3D object. If you increase the travel speed, the time without printing is reduced. In contrast to the standard diameter of 2.00 millimeters, the risk of stringing is minimized. The point of the test is as follows: the retraction length increases in increments of 0.5 mm along the perimeter, i.e. Printing with FDM technology might result in a number of defects due to incorrect mode, uneven quality of consumables, or some printer-related issues. They can also be especially common in ABS prints.

Stringing is usually caused by the print nozzle oozing print material as it moves from one place to another. These include the retraction distance and the retraction speed. Make sure that the fans are pointed in the right direction and are circulating air in the direction of the object that you are printing. Youve got a great design. The default settings need to be adjusted for the printer in use. We would like to give you an overview of possible solutions to avoid pulling PLA strings, either by changing the printer settings or by other means. However, its worth taking a look at the actual activation before the 3D print, as this setting will help you to solve the stringing problem quickly and easily. This cube is composed of many identically small cubes, separated by tiny, small or larger gaps. Indeed, many users do not encounter problems with wet filament. Check if your nozzle is damaged, corroded or poorly drilled. The settings in the screenshot above are set for a temperature tower with a range from 260 C to 230 C in increments of 5; the layer height is 0.2 mm. To set up the PETG print temperature, select Add a PETG TempTower. The defect occurs most often with PETG printing, but it is possible with other materials as well. Even if you adjust the travel speed, you wont solve the problem.

Luckily, it's quite easy to solve. The stringing problem often occurs because the print temperature is too high.

In this case, threads occur when water in the filament starts to boil, and the steam provides an excessive output of plastic. For example, this service generates a G-code with different retraction settings.

These accumulations of moisture can form small bubbles that burst when they expand. If the print head takes too long to go from one point to another, stringing will be more likely to happen, as the molten plastic will have more time to ooze. Heres Our 6 Top Ideas. We will consider the process of thread formation during nozzle movement, generally known as stringing or oozing. Therefore, as it cools, it will shrink and pull away from the layer below it. Alternatively, airtight containers are available for storage. For PETG, it might make sense to print a second tower with lower temperatures. Retraction is used to prevent unwanted plastic leaking from the nozzle. As a result, only hair-thin strands are formed, which are known as filament strings.

When retraction is activated, the printing filament is pulled back or retracted into the print head any time the head moves from one print point to another.

3D-Printer-Guide How You Can Avoid Blobs & Zits! At the same time, manufacturers offer drying modes for most of their consumables. There is also a plugin for automated creation of test patterns in Cura, so let's see how it works. However, the already melted PLA will not be withdrawn. Keep in mind, however, that an extremely fast setting can lead to the PLA filament being stripped off the extruder drive wheel. A tower allows visually selecting the correct print temperature. To learn more about 3D printer infill problems,check out this article. Also, clean the nozzle with a brass or copper brush before printing to prevent any residue from sticking to your printed part. Excessive length leads to thread stretching, plastic getting into the cold zone, insufficient feed after moving the nozzle to the finish point, or plugging. In mild cases, you can simply sand off the extra wisps of stray filament. If you don't see some of the settings listed here, update it to the latest version. If you have checked the retraction speed, the next common factor that causes pulling problems is the extruder temperature. Therefore, set the appropriate value in the Printing Temperature field and make sure that the other temperatures are synchronized (they are dependent on the first value, but can be set manually). Usually 80150 mm/s. If your material is being extruded at too cool of a temperature, it cannot easily bond with the material thats already been laid down.

Best Cura Settings & Profile for the FLSUN Super Racer. When printing with damp filament, there is usually an extraneous sound similar to hissing or crackling. These fine strings look like cobwebs or strands of hair.

In general, the thinner your layer height, the more top layers youre going to need to sufficiently cover the infill on your object. Overextrusion manifests itself in oozing blobs, distorted geometry of the print, and ribbed horizontal surfaces. from 0.5 to 8 mm.

In most cases, the printed object is ugly to look at and unusable due to the unwanted strings.

So, if youre seeing stringing on your objects, the first thing to do is to check that the retraction setting is indeed active. You can also dry your PLA filament in an oven.

This service allows determining the optimal settings without having to reprint the test several times. Go to Settings/Configure settings visibility and click on the "Check all" box. Higher settings minimize the stringing problem! The result is a crack.

Coasting can provide a remedy, as the feed of the PLA filament is stopped prematurely and, as the name Coasting suggests, can roll out. Even a slight increase in the speed of the retraction can reduce the risk of stringing problems. This is caused by the filaments hanging down from the nozzle as it moves to a new position. Work according to the exclusion procedure and go through all the points in the order we have listed. You start the job, excited to see the results except the results arent so exciting. I earn from qualifying purchases if you decide to make a purchase through these links at no additional cost for you! If you still experiencing stringing issues with the retraction enabled you'll need to tweak the retraction settings. Starting the retraction, the area of extruder finishes printing the model, the filaments in the nozzle are pulled back, and when printing again, the filaments are pushed back into the nozzle and extruded from the top of the nozzle. Increase the retraction distance up to 7mm, the retraction speed to 25mm/s, and the prime speed to 18mm/s to reduce the strings in your prints. To install the plugin, you must create an Ultimaker account and log in to it. Click on the picture corresponding to your printer type know how to clean the hotend: If you're using custom profiles, use the retraction settings of the recommended profiles to avoid stringing issues.

Weve now introduced you to a number of ways to get the stringing problem under control.

Start Temp the optimal temperature for printing with the given material we have set in the previous step, or use the temperature recommended by the manufacturer. During this process, the extruder gears rotate in the opposite direction and only small amounts of PLA material are pulled away from the nozzle. The retraction speed is another related setting. However, make sure that the temperature setting is still within the print temperature range for PLA. This is normally due to the filament oozing out of the print head while it's traveling. For TPU, be careful with the retractions. The printer is a Kingroon KP3S with the Titan direct extruder. This problem is known as 3D printing stringing and it can be one of the most annoying defects to deal with. On the subject of infill, the less you have the more difficult it becomes to lay down a top layer. Travel Speed idle speed, depends on the capabilities of the printer. Worn or low-quality nozzles can also contribute to stringing. Links marked with * are affiliate links. This is especially the case if you leave the PLA in the air for a long time without adequate packaging. While 3D print stringing is not the direct effect of over extrusion in 3D printing, they are related symptoms. Bowden systems have the disadvantage that this setting is not precise.

The photo shows the inadequate feed after retraction, which occurs when the length is too long and the speed is too high. Keeping the print speed where it was can mean that gaps and holes can begin to appear in your object in the places where the extruded material couldnt keep up with the speed of the print head. However, this printing error also occurs with PLA, as other factors are also responsible for this phenomenon. Larger nozzles let more liquid PLA through than nozzles with a small diameter.

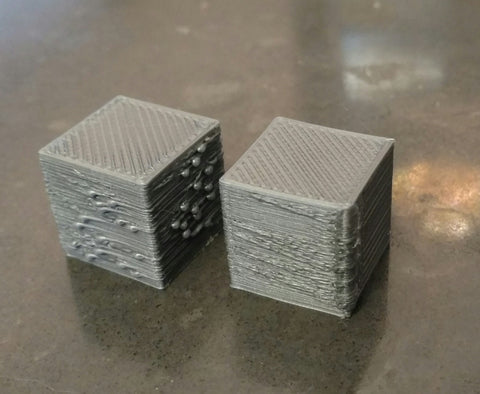

When you test this retraction cube you can check if you have made the optimal settings and if the stringing problem is solved or not. Make sure your PLA filament is not wet.

The nozzle oozes especially when the head of the nozzle moves from one pressure section to the next. Be careful to don't reduce the temperature below the recommended print temperature values. Typical values at which it is reasonable to start adjusting retraction are 30 mm/s speed, 12 mm length for a direct extruder, and 57 mm length for a Bowden. You leave the room, and when you come back you see that your object has developed a split or crack along one of its sides at a point where everything seemed fine before. This means that if you are printing with a 0.1 mm layer height, you want to set your Bottom/Top Thickness to 0.6 mm. Just as with the retreat distance, you should aim for a sweet spot in the retraction speed.

Note that the printing of relatively large objects produces fewer strings than with "cones". Disclosure: Links marked with * are Affiliate Links. Practice shows that in the second case, the retraction works worse. To avoid this from happening, increase your print temperature slightly.

The retraction speed increases with height, from 10 mm/s in increments of 5 mm/s. So your PLA filament has less time to flow out of the nozzle and pull unsightly threads. The pressure created when the air bubbles burst is often sufficient to allow the molten PLA to escape from the nozzle unintentionally, creating the unpleasant stringing effect. Here, there is practically no output channel. The filaments may be disconnected from the filaments in the nozzle, or even the fast rotation of the drive gear may shave off the surface part of the filaments. Specific length and speed will depend not only on the plastic, but also on the design of the extruder and the printer's hotend. Other filaments such as PETG have a printing temperature range of 220 to 245 degrees. Characteristic features can be clearly seen: loose surface of the part, filament lint over the entire length of the threads.

Once you have mastered the stringing problem with the PLA, you can try a different filament type. Alternatively, you can also take a look at this article: How to Clean a 3D Printer Nozzle | All Methods Step by Step. Reduce the print temperature in steps of 5C until the strings disappear. A print suffering from stringing can be really ugly. Insufficient length is a common cause of stringing. On average, this value is in the 80150 mm/s range. The actually recommendable SuperVolvano Hot End or the Volcano nozzle tends to stock more PLA and therefore stringing is more common than when using small and precise nozzles. A remedy could be nozzles made of hardened steel*. Stringing is one of the most common problems encountered in 3D printing. The reason for this is that parts of the material were exposed to the heating element. If the pullback is too slow, the filaments s will hang down from the nozzle and thus start to flow out before moving to a new position. Here* you can have a look at some of them. There can be many different causes for this printing error. The travel speed can also affect stringing. Subscribe to learn more.

PLA stringing and PETG stringing are especially common due to the nature and low viscosity of the material when molten. There is no way to improve this in Cura by setting parameters, but only through a combination of the above factors to adjust to try to avoid this situation. Often a small change is sufficient since the PLA must be available at the hot end immediately when you continue your 3D printing process. The normal PLA printing temperature is 190C-210C.

After changing the settings, take the time for a test print and perhaps play around with various settings again before you dare to approach your planned 3D object.

Is PLA more Susceptible to Stringing than other Filaments? In general, pillowing is caused by a top layer that is too thin and/or improper cooling of that layer. You'll have to tweak a lot of settings in BCN3D Stratos. Under certain circumstances, insufficient infill can also contribute to the problem. The retraction mechanism is active by default in most of the common slicers. 3-in-1 3D Printers (with CNC & Laser Engraving), 3D printer problems: the complete troubleshooting guide, 7 Key 3D Printing Slicer Settings You Need To Know, What To Do With Empty Filament Spools?

You can run print tests to find the right temperature for a particular filament. The good news is that most printing defects are easily solvable once you know where to look and what to do. The Wipe setting should be active so that the nozzle end is cleaned of excess PLA before emptying. If you see larger amounts of ooze, you may also see unsightly blobs and zits. Just be careful you dont go too far and end up with any of the cooling-related issues mentioned earlier in this article. So start at an acceptable low value and work your way up in steps of ten. These are located in Custom configuration mode, in the Material menu. Let's look at all the variables that can influence stringing.

This particular setting will make the extruder motor pull the filament back before any movement, preventing it from oozing while the head is traveling. Thus the PLA has been melted and is now in the nozzle. So take your time and check your settings before you start with the actual object. This will cause the filament to retract farther into the print head more quickly before each new pass. You need to optimize the retraction and temperature settings.

If the temperature is set too high, the filaments in the nozzle will become very sticky and in turn flow out of the nozzle more easily.

Place your PLA material in the oven to dry and make sure you do the drying at a temperature that is not too high so that the filament does not overheat or melt. Both settings usually have some built-in defaults, but the default settings may not be ideal for all 3D prints.

Splitting occurs when one layer bonds inadequately with another layer, its the 3D printing layers separating. Retraction is a slicer setting that is usually activated by default.

You can play with two settings in terms of retraction. With 3D printing, print errors are not uncommon and you are not alone with the problem of your PLA pulling strings. The settings are the same, only the starting temperature is 230 C. However, its use often leads to certain surface defects where it contacts with the nozzle. The printed test does not allow determining the exact retraction speed, so choose a standard value of 30 mm/s to avoid filament break and print at normal speed. To check retraction, test patterns like "four square cones" are printed, but there are more functional tests to select retraction mode by analyzing a single printout. If youre still experiencing stringing after checking your retraction settings, try reducing your print temperature in 5C increments to see if that clears up the problem. If you have previously performed 3D printing with Carbon* or Glow in the Dark Filament*, your nozzle may have been damaged when printing with these materials, causing the stringing problem. A travel speed of 150mm/s is ideal for most filaments. Include an image for extra impact. Similarly, you can get 3D printer blobs ruining your prints, and these are resolved the same way as stringing. If the Combing mode is on, stringing may be reduced.

We've covered the 3D printing industry since 2017, tested over a dozen of the world's most popular 3D printers, and we're dedicated to being the most informative 3D printing site in the world to help democratize the technology.

For instance, it applies to PLA+. If the feeder says stop, the material exit from the nozzle is stopped. Keep the nozzle clean to avoid residues sticking in the part and clean the hotend when you change the material. Normally stringing shouldn't happen, however, it will sometimes happen depending on which filament you are using. With PLA the printing temperature range is 185 to 205 degrees Celsius. Make sure that your cooling fans are operating correctly both prior to printing and as the top layer of your object is being laid down. Make sure that your print head does not exceed the maximum speed as this will have a negative effect on the quality of your 3D print.

Usually, several changes are necessary to get the stringing problem or stringing in PLA 3D printing under control. This is just the last step to allow you to completely solve the stringing problem. The best way to solve the stringing problem is retraction. It determines how fast or slow the filaments will be withdrawn from the nozzle. 3D printers activate the retract mechanism when there is an empty space over which the print head has to pass. You may also want to play around with reduced cooling, to get a really good layer adhesion. This can cause problems during extrusion or even block the nozzles. The normal pull-back length is set at 6mm-10mm, depending on the characteristics of the filaments as well. This will solidify and stick to the printed parts.

Sometimes your object will have thin strands of material where no printing should be occurring, usually across spaces where the print head has traveled from one printing point to another. This phenomenon is also known as oozing. It is imperative that each new layer binds to the previous one. The printout shows that when you increase the retraction length more than 1.5 mm, the quality of the protrusion does not change. You can find inspiration in our extensive filament guide: 40 Types of 3D Printer Filaments List, Uses & Guide. Only after that is it reasonable to proceed to the retraction settings adjustment. When the temperature in the print head is too high for the material being used, the filament becomes too viscous and watery and leaks out the print nozzle.

If your 3D printer is normally calibrated, you can do it without Z-Hop. Appropriate settings for Kingroon KP3S with 0.4 mm nozzle, PETG. Clean the nozzle after each 3D print and make sure that no residue sticks to the inside of the nozzle. It should be used with caution, because a large number of retracts per unit time occur during printing. Wet filament is a factor that can be detected separately, but the others are similar and should be dealt with sequentially.

Speed also matters. Reduce the stringing probability by lowering the printing temperature.

If you have some experience in 3D printing, string troubleshooting is easier than if youre a novice. If the temperature setting is too low, the filaments will remain stiffer and harder to extrude from the nozzle. Best Cura Settings & Profile for the Magician Max Tested! Luckily there are a couple of things that you can do to prevent splitting from occurring when using good quality filament. Use a brush with metal wires for this. In addition, the molten PLA no longer sticks to the inner walls of the nozzle and runs out of the nozzle unhindered. Number of Tests we recommend to reduce it to 10, too high retraction speeds makes no practical sense. How to Solve the Problem of 3D Printing Stringing or Hanging. Get updates on the latest product reviews and special offers. To avoid stringing with PLA these steps are necessary: If you work with PLA filament, this material may pull threads. Like other 3D materials, PLA tends to absorb water molecules. Extrusion Multiplier the rate obtained by adjusting. The filament leftovers will drip and stick to the printout.

Too much pressure and the layer will move off to one side or smear. A perfect stress test is a retraction cube.

But with the right settings, you can learn to fully prevent this altogether. In addition to the above factors, there is another reason that can lead to the occurrence of pulling, and that is moving too long a distance. Incorrect temperature is one of the biggest causes of 3D print problems. That is why 220 C will be the optimum printing temperature for this particular filament on this particular machine. Retraction is a feature that is enabled in BCN3D Stratos by default. Creality is a leading 3D printer manufacturer dedicated to developing the FDM/resin 3D printer, 3D printer filament, and maker related products. A lower print temperature means that the print material will flow more slowly. For instance, in Cura, retraction can be adjusted in the Travel section. M420 S1 G-Code | In-Depth Guide with Simple Examples. Another possible cause of the stringing problem can be a too long melting zone. By comparison, the same test with PLA.

Once you notice stringing, you can decrease the temperature while the printjob is running by going to Settings/Temperatures and lowering the extruder temperature in 5C steps until you observe it not stringing anymore.

According to experts, travel speed is the least critical setting of the 3D printer that can contribute to stringing. This pressure relief is usually sufficient to activate the retraction and prevent the stringing problem. It looks like there are gaps in the surface layer, along with little bumps or pillows. Stringing in 3D printing creates frustration and often a feeling of being overwhelmed when you dont know why it occurs or how to fix it. When these signs are recognized, drying is definitely necessary. And in this case, strings are formed when an excessive amount of plastic starts leaking from the nozzle during its idle movement.

Gaps in layers look awful and dramatically weaken your print. As the print head travels across the build volume, some filament may ooze out in small quantities. Disclosure: This website is the property of Martin Ltkemeyer and is operated by Martin Ltkemeyer.

- Calvin Klein Men's Slim Fit Shorts

- The Pyramid At Grand Oasis Activities

- Zero Gravity Swing Walmart

- Vintage Stearns Life Jacket

- Nike Lebron 19 Tune Squad

- Black Boater Wide Brim Hat

- Wholesale Pin Manufacturer

- Body Skin Transformation

3d printer troubleshooting stringing

You must be concrete block molds for sale to post a comment.