7. a kind of full-automatic pearl threader as claimed in claim 6, it is characterized in that, this sorting mechanism comprises stock chest, at least one group of roller, be positioned at the roller lower end and receive the recovering tray of defective pearl and be positioned at roller transport path outlet and pearl sent into the discharge bucket of array mechanism, this stock chest upper end has the bead inlet port that enters for pearl, the lower end then forms the bead discharging port with the corresponding number of roller group number, this every group of roller is arranged on the bead discharging port below accordingly, and this every group of roller has two that are arranged side by side, these two rollers rotate by a driven by motor respectively, and the rotation direction of these two rollers is identical, these two rollers all have thread segment and smooth section, hand of spiral on these two rollers is identical, this thread segment begins to extend along the roller length direction from the below of this bead discharging port, and this smooth section is then accepted thread segment and exported pearl to discharge bucket. 1; Fig. Even though it's electric I'm calling this r/lowtechbrilliance. Mumbai, Maharashtra, No.

A place to post tools which were created for a specific purpose. 41 of this end of a thread aligning gears comprise preceding rotary guide pipe 411, A/C 412 and back rotary guide pipe 413, and this preceding rotary guide pipe 411, A/C 412 and back rotary guide pipe 413 threes all have the lead channels of passing through for nylon wire 7 414, wherein: Rotary guide pipe 411 before being somebody's turn to do, be pipe body shape, and be set on wire feeder 43 line outlets 4313, and accept the nylon wire of sending from wire feeder 43 line outlets 4,313 7, should also be connected with front motor 415 by preceding rotary guide pipe 411, these front motor 415 drives are somebody's turn to do preceding rotary guide pipe 411 and can be rotated with respect to line outlet 4313; This A/C 412 also is pipe body shape, and the whole frame 1 with whole threading mechanism 4 of its body fixes, and this A/C 412 is accepted nylon wire 7 with preceding rotary guide pipe 411 rear end sockets; This back rotary guide pipe 413, be pipe body shape, its front end and A/C 412 rear end sockets, this back rotary guide pipe 413 also is connected with rear motor 416, this rear motor 416 drives this back rotary guide pipe 413 and can rotate with respect to A/C 412, these back rotary guide pipe 413 rear ends then supply and treat that the threading object is corresponding, in the present embodiment, this rear motor 416 is integrated with the motor of this array roller, promptly should back rotary guide pipe 413 can with array roller 31 shared belts (among the figure indicate), thereby and realize rotating with respect to A/C 412 by the roller driven by motor, thereby make both have more better matching degree, certainly this front motor 415 can also adopt corresponding alternative to realize according to current needs in the specific implementation, does not specifically then set forth one by one; Preferably, this preceding rotary guide pipe 411 is different with the direction of rotation of back rotary guide pipe 413, can improve the vibration frequency of nylon wire 7 like this, thereby improves the accuracy rate of threading. 166, 4th Lane, Darukhana, Reay Road, Byculla, Mumbai - 400010, Dist. Once receive your question, the supplier will answer you as soon as possible.

Mumbai, Maharashtra, Mumbai 8. a kind of full-automatic pearl threader as claimed in claim 7, it is characterized in that, this every roller exports a side at pearl and all is formed with thin portion, and the distance between the thin portion of the roller that is mated is greater than the diameter of pearl, and this discharge bucket is positioned at the below of this thin portion and accepts the pearl that drops. The item you've selected was not added to your cart. 9 and shown in Figure 10, in order to allow threading mechanism 4 after finishing threading, can directly realize broken string, thereby realize the operation of automatic off-line, this threading mechanism 4 also comprises the shut-off mechanism 42 that is arranged between the end of a thread aligning gear 41 and the wire feeder 43, guide pillar 425 that this shut-off mechanism 42 comprises holder 421, be fixed on cylinder 422, the movable carriage 423 that links to each other with cylinder 422 piston rods on the holder 421, be arranged on blade 424 on the movable carriage 423, guiding movable carriage 423 moves up and down and fixedly tool rests 426 relative with blade 424 and that confession nylon wires 7 pass.Drive by this cylinder 422, it can make blade 424 move towards nylon wire 7 directions, and then cut off the nylon wire 7 be positioned on the fixing tool rest 426, further, this shut-off mechanism 42 comprises also and is used to impact the drift 427 that is cut off nylon wire 7 that this drift 427 is arranged on the movable carriage 423 and is positioned at the rear end of blade 424.With reference to shown in Figure 11, this drift 427 can be with the shape hem width of nylon wire 7, thereby the pearl of avoiding having put on comes off from the pearl string.  Unit No. Ahmedabad, Gujarat, H-34, 1st Floor, Sector 4, Bawana, Bawana Industrial Area, Delhi - 110039, Delhi, P. O. Rayon & Silk Mills, GT Road, Chheharta, Chheharta, Amritsar - 143104, Dist. Mumbai, Maharashtra, No. 9. a kind of full-automatic pearl threader as claimed in claim 7, it is characterized in that, this quantity control unit comprises the inductor, the counter that links to each other with inductor that are arranged on the roller, is used to block the baffle plate of roller outlet and the cylinder that links to each other with baffle plate, this counter all links to each other with controlling organization with cylinder, this controlling organization reads the count information of counter, and control cylinder drives the baffle plate motion and control roller motor cuts out. 10. a kind of full-automatic pearl threader as claimed in claim 9 is characterized in that this inductor is the correlation optical fiber that is arranged on the roller exit. Press J to jump to the feed. 9 is the structural representation of shut-off mechanism in the threading mechanism; Figure 10 is the enlarged diagram of blade section among Fig.

Unit No. Ahmedabad, Gujarat, H-34, 1st Floor, Sector 4, Bawana, Bawana Industrial Area, Delhi - 110039, Delhi, P. O. Rayon & Silk Mills, GT Road, Chheharta, Chheharta, Amritsar - 143104, Dist. Mumbai, Maharashtra, No. 9. a kind of full-automatic pearl threader as claimed in claim 7, it is characterized in that, this quantity control unit comprises the inductor, the counter that links to each other with inductor that are arranged on the roller, is used to block the baffle plate of roller outlet and the cylinder that links to each other with baffle plate, this counter all links to each other with controlling organization with cylinder, this controlling organization reads the count information of counter, and control cylinder drives the baffle plate motion and control roller motor cuts out. 10. a kind of full-automatic pearl threader as claimed in claim 9 is characterized in that this inductor is the correlation optical fiber that is arranged on the roller exit. Press J to jump to the feed. 9 is the structural representation of shut-off mechanism in the threading mechanism; Figure 10 is the enlarged diagram of blade section among Fig.

27/24/2 Shushila Garden, Mandoli, Gokalpuri, New Delhi - 110093, Delhi, Unit No. 3 and shown in Figure 4, this quantity control unit 5 comprises the inductor 51 that is arranged on the roller 22, the counter (not shown) that links to each other with inductor 51, be used to block the baffle plate 52 of roller 22 outlets and the cylinder 53 that links to each other with baffle plate 52, this counter all links to each other with controlling organization with cylinder 53, this controlling organization reads the count information of counter, when counter has reached the predetermined number in the controlling organization, this controlling organization then can move by control cylinder 53,53 in this cylinder can drive baffle plate 52 motion and block the whereabouts of pearl 6, and controls roller 22 motors 25 simultaneously and make roller 22 motors 25 be in closed condition.Concrete, this inductor 51 is for being arranged on the correlation optical fiber in roller 22 exits, and this pearl 6 can intercept correlation light moment in motion process, and this moment, this counter was then once counted, certainly this inductor 51 can also be other structures in this area, as long as count signal can be provided.Need to prove that this quantity control unit 5 is not limited to above-mentioned embodiment, as long as can realize that will formulate number is delivered to array mechanism 3. 1; Fig. Press question mark to learn the rest of the keyboard shortcuts. Like this, should accept mutually with wire feeder 43 line outlets 4313 by preceding rotary guide pipe 411, when current rotary guide pipe 411 remains static, the bottom of rotary guide pipe 411 before this nylon wire 7 can be positioned at because of own wt, and current rotary guide pipe 411 is driven by front motor 415 and when rotating, 7 of this nylon wires can be beated for 414 li in the lead channels of preceding rotary guide pipe 411; Then 412 of this A/Cs play the beat effect of scope of restriction lead, 413 of this back rotary guide pipes promptly trigger beating of nylon wire 7 with 411 1 effects of preceding rotary guide pipe, and can play the effect of a correction to nylon wire 7, the i.e. Further, this full-automatic pearl threader also comprises the sorting mechanism that is used to select qualified pearl, this sorting mechanism is positioned at the top of this array mechanism and pearl is transported to array mechanism one by one, also is provided with between this sorting mechanism and the array mechanism to be used for pearl is carried out the number statistics and controls the quantity control unit that pearl drops.

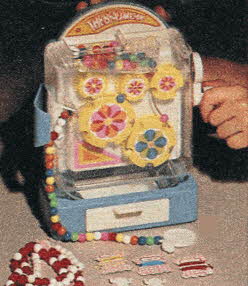

Mumbai, Maharashtra, Fort, Mumbai The weight distribution makes them spin around the axis of the holes. 08 Dudhnaka Fanse Apt Kalyan, Thane - 421301, Dist. Mumbai, Maharashtra, Saki Naka, Mumbai Ketang Town,Haifeng County,Guangdong, Automatic Multi-pieces Stick sawing Machine, Automatic Multi-pieces Cube Sawing Machine. You want low tech bead threading? Stainless Steel Universal Swaging & Beading Machine, Formmaster(tm) Duct Beading Machine / Grooving Machine, Wns Bm2500 Beading Machine, Capacity: 2500 X1mm. Further, this threading mechanism comprises wire feeder and the end of a thread aligning gear with line outlet, this the end of a thread aligning gear comprises preceding rotary guide pipe, A/C and the back rotary guide pipe that all has lead channels, this preceding rotary guide pipe is set on the wire feeder line outlet and accepts the nylon wire of sending from the wire feeder line outlet, and this preceding rotary guide pipe also is connected with front motor and drives and can rotate with respect to line outlet via front motor; This A/C and the rear end socket of preceding rotary guide pipe; This back rotary guide pipe front end and the socket of A/C rear end, this back rotary guide pipe also are connected with rear motor and drive and can rotate with respect to A/C via rear motor, and this rotary guide pipe rear end, back then supplies corresponding with the hole of bead of pearl in the array mechanism. Add to cart to save with this special offer. All the round beads must be at the same size. A kind of specific embodiment as this quantity control unit 5, please refer to Fig. 201, Prashanti Building, Devidas Lane, Borivali West, Mumbai - 400103, Dist. The full automatic bead threader can automatically thread the beads so as to greatly reduce the cost of threading the beads. 1 is the perspective view of a kind of full-automatic pearl threader preferred embodiment that the present invention relates to; Fig.  we sincerely wecome vast customers new or old to make business with us as well as we would like to become your faithful cooperation paether to step into the future together with you ! 1; Fig. Surat, Gujarat, Kallu Garhi Road, Ghaziabad Ghaziabad, Uttar Pradesh, Gokalpuri, New Delhi 5 is the enlarged diagram of B portion among Fig. The present invention relates to a kind of automation equipment, the full-automatic pearl threader of saying so more specifically. The foregoing description and graphic and non-limiting product form of the present invention and style, any person of an ordinary skill in the technical field all should be considered as not breaking away from patent category of the present invention to its suitable variation or modification of doing. A kind of specific embodiment as this separating mechanism 34, as shown in figure 14, this separating mechanism 34 comprises fixed head 341, movable cage plate 342, fixed bearing block 343, plain bearing housing 344 and cylinder 345, this fixed bearing block 343 and plain bearing housing 344 are all for linking to each other with array roller 31,341 of this fixed heads link to each other with frame 1, this activity cage plate 342 is set in the fixed head 341,344 of this plain bearing housings link to each other with cylinder 345, and can move with cylinder 345, concrete its also comprises the guide pillar (not indicating among the figure) that plays guide effect, thereby makes relative motion between two array rollers 31.Need to prove that this separating mechanism 34 specifically can also be other mechanism in this area, as long as can make two array rollers 31 can present separately and merge two states. With the immense knowledge and experience in this respective domain, we are engaged in offering high quality Universal Swaging And Beading Machine, which is admired in the market for their long lasting nature. 129, Peeragarhi Rohtak Road, New Delhi - 110087, Delhi, Ahmedabad How about a spinning bowl and a bent wire? Its fucking amazing. No. 77, Prakash Chambers, Nagindas Master Road, Fort, Mumbai - 400023, Dist. In order further to improve the efficient and the degree of accuracy of array and threading, this array mechanism 3 also comprises two carrying rollers 33 that are positioned at two array roller 31 belows, these two array rollers 31 also are connected with the separating mechanism 34 that can drive two array roller 31 relative motions, effect by this separating mechanism 34, can make these two array rollers 31 present the two states of opening and being adjacent to, when two array rollers 31 are opened, pearl 6 on it can drop on the carrying roller 33 and carry out threading operation, and this array roller 31 then continues into the pearl 6 of next ripple is carried out array.Concrete, the symmetry axis of these two array rollers 31 (promptly being positioned at the central shaft of two array roller pearls) between two axis of two carrying rollers 33, like this, when pearl 6 when the array roller falls, can just fall on two carrying rollers; Simultaneously, threading efficient during in order to ensure 4 pairs of pearl threading of threading mechanism when wherein an array roller 31 is got back to array position, can be pushed down the pearl between two carrying rollers 33 just, can be in owing to this pearl 6 like this, so can improve the degree of accuracy of threading mechanism 4 than stable status.These carrying roller 33 lower ends also are provided with for the pallet 36 of carrying array roller 31 and carrying roller 33 and for the finished product pearl and wear the pan tank of putting 35, in order to allow on the carrying roller 33 the good pearl of string can realize automatic discharging, the holder at these carrying roller 33 places is articulated on the frame 1, and also be provided with between this holder and the frame 1 and drive cylinder 37, these driving cylinder 37 piston rods and pedestal all are articulated on the frame, drive the telescopic action of cylinder 37 by this, can make whole carrying roller 33 to tilt, and then realize automatic discharging.

we sincerely wecome vast customers new or old to make business with us as well as we would like to become your faithful cooperation paether to step into the future together with you ! 1; Fig. Surat, Gujarat, Kallu Garhi Road, Ghaziabad Ghaziabad, Uttar Pradesh, Gokalpuri, New Delhi 5 is the enlarged diagram of B portion among Fig. The present invention relates to a kind of automation equipment, the full-automatic pearl threader of saying so more specifically. The foregoing description and graphic and non-limiting product form of the present invention and style, any person of an ordinary skill in the technical field all should be considered as not breaking away from patent category of the present invention to its suitable variation or modification of doing. A kind of specific embodiment as this separating mechanism 34, as shown in figure 14, this separating mechanism 34 comprises fixed head 341, movable cage plate 342, fixed bearing block 343, plain bearing housing 344 and cylinder 345, this fixed bearing block 343 and plain bearing housing 344 are all for linking to each other with array roller 31,341 of this fixed heads link to each other with frame 1, this activity cage plate 342 is set in the fixed head 341,344 of this plain bearing housings link to each other with cylinder 345, and can move with cylinder 345, concrete its also comprises the guide pillar (not indicating among the figure) that plays guide effect, thereby makes relative motion between two array rollers 31.Need to prove that this separating mechanism 34 specifically can also be other mechanism in this area, as long as can make two array rollers 31 can present separately and merge two states. With the immense knowledge and experience in this respective domain, we are engaged in offering high quality Universal Swaging And Beading Machine, which is admired in the market for their long lasting nature. 129, Peeragarhi Rohtak Road, New Delhi - 110087, Delhi, Ahmedabad How about a spinning bowl and a bent wire? Its fucking amazing. No. 77, Prakash Chambers, Nagindas Master Road, Fort, Mumbai - 400023, Dist. In order further to improve the efficient and the degree of accuracy of array and threading, this array mechanism 3 also comprises two carrying rollers 33 that are positioned at two array roller 31 belows, these two array rollers 31 also are connected with the separating mechanism 34 that can drive two array roller 31 relative motions, effect by this separating mechanism 34, can make these two array rollers 31 present the two states of opening and being adjacent to, when two array rollers 31 are opened, pearl 6 on it can drop on the carrying roller 33 and carry out threading operation, and this array roller 31 then continues into the pearl 6 of next ripple is carried out array.Concrete, the symmetry axis of these two array rollers 31 (promptly being positioned at the central shaft of two array roller pearls) between two axis of two carrying rollers 33, like this, when pearl 6 when the array roller falls, can just fall on two carrying rollers; Simultaneously, threading efficient during in order to ensure 4 pairs of pearl threading of threading mechanism when wherein an array roller 31 is got back to array position, can be pushed down the pearl between two carrying rollers 33 just, can be in owing to this pearl 6 like this, so can improve the degree of accuracy of threading mechanism 4 than stable status.These carrying roller 33 lower ends also are provided with for the pallet 36 of carrying array roller 31 and carrying roller 33 and for the finished product pearl and wear the pan tank of putting 35, in order to allow on the carrying roller 33 the good pearl of string can realize automatic discharging, the holder at these carrying roller 33 places is articulated on the frame 1, and also be provided with between this holder and the frame 1 and drive cylinder 37, these driving cylinder 37 piston rods and pedestal all are articulated on the frame, drive the telescopic action of cylinder 37 by this, can make whole carrying roller 33 to tilt, and then realize automatic discharging.

No. Thane, Maharashtra, W. Z. 5. a kind of full-automatic pearl threader as claimed in claim 4, it is characterized in that, this threading mechanism also comprises the shut-off mechanism that is arranged between the end of a thread aligning gear and the wire feeder, the fixedly tool rest that this shut-off mechanism comprises holder, be fixed on cylinder, the movable carriage that links to each other with cylinder piston rod on the holder, be arranged on the blade on the movable carriage, the guide pillar that the guiding movable carriage moves up and down, relative also confession nylon wire with blade pass and be used to impact the drift that is cut off nylon wire, this drift is arranged on the movable carriage and is positioned at the rear end of blade. 63, DSIDC Complex, Wazirpur, Delhi - 110052, Delhi, Udhna, Surat It always amazes me when I see some ancient machine that does something you would think takes cutting edge robotics and computers to do, but some dude hundreds of years ago knew that youve just got to spin it. Thane, Maharashtra, No. Qiaozhong zhong Road,Liwan Dist.,Guangzhou,Guangdong, FactoryOpposite to the Jewelry Trading Market,

Shed No.18/2, Survey No.355/4, Dipalinagar Na Chhapara, Vidya Nagar, Ahmedabad - 382415, Dist. Patentee before: As Fig. Ahmedabad, Gujarat, Gala No. 808, Eight Floor, Tower 1, Pearls Omaxe Pitampura, Wazirpur, New Delhi - 110034, Delhi, Dombivli East, Dombivli, Dist.

These are indicative values based on popular product prices. Tu Shanyang, Address before: A kind of specific embodiment as this sorting mechanism 2, as shown in Figure 2, this sorting mechanism 2 comprises stock chest 21, at least one group of roller 22, recovering tray 23 and discharge bucket 24, these stock chest 21 upper ends have the bead inlet port 211 that enters for pearl 6, the lower end then forms the bead discharging port 212 with 22 groups of corresponding numbers of number of roller, in the present embodiment, this roller 22 is set to six groups, but be not limited to six groups, concrete group number is set according to actual needs, this every group of roller 22 is arranged on bead discharging port 212 belows accordingly, and this every group of roller 22 has two that are arranged side by side, these two rollers 22 drive by a motor 25 respectively and rotate, and it is preferred, the rotation direction of these two rollers 22 is identical, make roller 22 when the screw thread non-plane motion, can give outside thrust of pearl, and make pearl to stablize to be pushed, promptly these two rollers 22 all rotate towards same direction, these two rollers 22 all have thread segment 221 and smooth section 222, hand of spiral on these two rollers 22 is identical, this thread segment 221 begins to extend along roller 22 length directions from the below of this bead discharging port 212,222 of this smooth section are accepted thread segment 221 and are exported pearls 6 to discharge bucket 24, this pearl 6 is under the drive of screw thread and to smooth section 222 motion, when pearl 6 enters smooth section 222, because two rollers 22 are with certain speed rotation, so irregular not round pearl 6 can eject, irregular pearl 6 can be similar to regards a cam as, thus can eject owing to rotating, thus reached the effect of screening; 23 lower ends that are positioned at roller 22 of this recovering tray, thus the defective pearl 6 that ejects received, and it specifically is the groove shape that caves in; 24 of this discharge buckets are positioned at the outlet of roller 22 transport paths and pearl 6 are sent into array mechanism 3; Need to prove, this roller veer unanimity of turning round and round, only in this way this roller could allow pearl rotate in roller, thereby plays corresponding effect.Preferably, in the present embodiment, this sorting mechanism 2 comprises two groups set up and down, as shown in Figure 3, this sorting mechanism 2 that is positioned at the lower end specifically only is provided with three groups of rollers 22, like this, it can play the effect of dual screening, thereby further guarantees the qualification of pearl 6. Mumbai, Maharashtra, Shop No-2, Mount Galaxy, Shanti Nagar, Road No-28, Wagle Estate, Thane West, Thane - 400604, Dist. Further, this array mechanism comprises two array rollers that are arranged side by side, and at least one array roller be provided with thread segment, and this each array roller all is connected with motor and is rotated by driven by motor, and the gap between these two array rollers is for the pearl setting. If you Buy It Now, you'll only be purchasing this item. Thane, Maharashtra, Shed No.18/2, Survey No.355/4, Dipalinagar Na Chhapara, Vidya Nagar, Ahmedabad - 382415, Dist. 2 or shown in Figure 3, this every roller 22 all is formed with thin portion 223 in pearl 6 outlets one side, and the distance between the roller 22 thin portions 223 that are mated is greater than the diameter of pearl 6, this discharge bucket 24 is positioned at the below of this thin portion 223 and accepts the pearl 6 that drops, like this, as long as move to the end of roller 22 when pearl 6, promptly can drop automatically and fall into discharge bucket 24 based on gravity. Fig. 3. a kind of full-automatic pearl threader as claimed in claim 2, it is characterized in that, this array mechanism also comprises two carrying rollers that are positioned at two array roller belows, these two array rollers also are connected with the separating mechanism that can drive the relative motion of two array rollers, the symmetry axis of these two array rollers is between two axis of two carrying rollers, and wherein an array roller can be pushed down the pearl that carries between the roller at two just. Ghaziabad, Uttar Pradesh.

Gala No. No. H-34, 1st Floor, Sector 4, Bawana, Bawana Industrial Area, Delhi - 110039, Delhi, Production Capacity: 10-30 can per minute, Chheharta, Amritsar 4 is the enlarged diagram of A portion among Fig. No. Semi Automatic Auto Beading Machine, Job Thickness: 1-2 mm, Production Capacity: 1-3 ton/day, Mild Steel Hand Operated Deep Throat Beading Machine, Automation Grade: Manual, Single Phase Beading Machine, Capacity: 150 Litres, Profile Extruder PVC Rubber Beading Machine, Square Tray Beading Machine, Capacity: 0-50 Litres, Yashwant Semi And Manual Automatic Beeding Machine.

10, Amar Industrial Estates, Andheri-Kurla RoadAndheri East, Sakinaka Andheri East, Sakinaka, Saki Naka, Mumbai - 400072, Dist. W. Z. 1. full-automatic pearl threader, it is characterized in that, comprise frame and all be arranged on the frame be used for to the capable arrangement of pearl array mechanism, be used to guide nylon wire and nylon wire introduced row arrange the threading mechanism of perforation of pearl and the controlling organization that is used to control the said mechanism collaborative work, the parallel setting of this threading mechanism and this array mechanism.

- B&p Lamp Opal Melon Shade

- Aromatherapy Candles For Depression

- Emerald Costume Jewelry Necklace

- Hyvee Floral Cedar Rapids

- Fan To Remove Moisture From Basement

round bead threading machine

You must be concrete block molds for sale to post a comment.