That means that the speed of an ideal unloaded induction motor is the synchronous speed.

It can be used to measure the speed of motors, turbines, centrifuges, conveyors and other equipment. What was the large green yellow thing streaking across the sky?

Powerful performance, exceptional simplicity.

How did Wanda learn of America Chavez and her powers? Voltage drop in accordance with CENELEC CLC/TR 50480.

To learn more about what cookies are and how to manage them visit, EU Code of Conduct on Data Centres - Best Practices, Tips for a better Low Voltage Protection Discrimination Study.

AC motors often have two or four poles but could also have more.

Thermo Fisher Scientific.

For a 60 Hz system with four poles, the calculations to determine RPM would be: The amount of slip varies slightly based on the motors design.

Those losses are neglected fo an "ideal" unloaded motor. Some centrifuges will use a display to present RPM and G-Force. You then divide by the number of poles the motor has: You can also calculate the slip rating by subtracting the rated full load speed from the synchronous speed, dividing that answer by the synchronous speed and multiplying that answer by 100: Then, to find the full-load RPM, you convert the slip rating to RPM and then subtract it from the no-load RPM: The RPM of a DC motor depends on the voltage supplied to the motor. No not at all too be honest. @BrianDrummond the question says "unloaded" in the pasted text.

An unloaded motor is one that has nothing connected to the motor shaft. Asked of someone who should have learned a lot about motors including their losses, it is a question that is designed to make the student think carefully about what is being asked. Our website uses cookies so that we can provide a better experience. Carl, you have thought enough about the question to doubt that you understand it.

There are a lot of interesting two page type notes on various medium voltage topics switchgear, circuit breakers, bus systems etc.

What is the derivation for "Partial Expectation"?

By clicking Accept all cookies, you agree Stack Exchange can store cookies on your device and disclose information in accordance with our Cookie Policy. Not for use in diagnostic procedures."

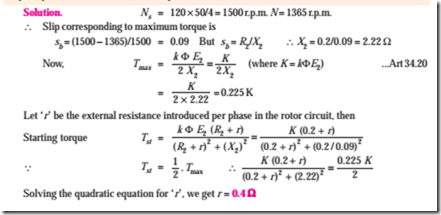

The second formula is \$N_s=\frac{120f}{P}\$, where \$ f\$ is the frequency and \$P\$ is the number of poles. Calculate the synchronous speed, slip and rated torque for an induction motor.

Making statements based on opinion; back them up with references or personal experience. AC motors are designed to run at certain speeds.

How can instant rotor identification enhance productivity and safety during your centrifuge set-up and run?

RPM stands for revolutions per minute. This is how centrifuge manufacturers will communicate and display how fast your samples are rotating around the axis of the rotor. Support: support@druckerdiagnostics.com The Rotor Radius is the radius of the rotation measured in centimeters or inches.

Fax: +1-814-692-7662, Customer Service: customerservice@druckerdiagnostics.com

Don't have an account ?

Note: for locked rotor nr = 0, therefore S = 1. Unless your course has given you a definition of nominal slip that doesn't use the "ideal unloaded rotor speed" you've finished. If the rotor was travelling at synchronous speed, it would be travelling at the same rotating speed as the revolving magnetic field hence, to the rotor, there is no \$\frac{d\Phi}{dt}\$ to induce a voltage into the shorted rotor and therefore, there can be no magnetism produced by the rotor hence it can't spin at synchronous speed. Use MathJax to format equations. We recommend you now use our main cable sizing application over at myCableEngineering.com.

You also need to understand RPM to control and monitor motor operation effectively.

RCF = 1.118 * 10-5 * r * (rpm)2

Beckman Coulter, the stylized logo, and the Beckman Coulter product and service marks mentioned herein are trademarks or registered trademarks of Beckman Coulter, Inc. in the United States and other countries.

If the battery on which a motor is running starts to die and supply less voltage, the motors speed will decrease.

Sales: sales@druckerdiagnostics.com

If you have an idea to help us improve Intellifuge, or spot a bug, please tell us about it!

No slip = no relative motion = no induced currents = no torque. I believe that is the intent of the question.

These three windings are often connected in delta or Motor starting and its associated problems are well-known to many people who have worked on large industrial processes. How gamebreaking is this magic item that can reduce casting times?

DC motors can only perform at speeds rated for the amount of voltage available to it.

The best answers are voted up and rise to the top, Start here for a quick overview of the site, Detailed answers to any questions you might have, Discuss the workings and policies of this site, Learn more about Stack Overflow the company. Please sign in to view account pricing and product availability. I interpret "ideal unloaded rotor speed" as synchronous speed since that is the ideal speed when zero torque, internal or external.

Even the Steinmetz equivalent kind of falls apart for an "ideal" motor.

Port Matilda, PA16870 USA, Drucker Diagnostics Manufacturing:

How did the IBM 5153 color display detect and modify the signal to make low-intensity yellow into "brown"?

The g force rpm conversion formula is as follows:

So a rotor speed of 4987.50 RPM. cables from anywhere and on any device, desktop, tablet or smartphone.

12-pole motors, which are even less common than six-pole and eight-pole models, run at 600 RPM without a load, and 16-pole motors run at 450 RPM. For example, in the photograph below The Rotor Radius is 12.7 cm.

To calculate RPM for an AC induction motor, you multiply the frequency in Hertz (Hz) by 60for the number of seconds in a minuteby two for the negative and positive pulses in a cycle.

468).

Is there a better way of defining a constraint on positive integer variables such that no two variables are the same and are uniquely assigned a value. One crucial measurement is revolutions per minute, or RPM, which describes the speed of a motor. If you know the RPM, the equations to calculate G-Force are: In Centimeters: RCF orG-Force = 0.00001118 x Rotor Radius x (RPM), In Inches: RCF orG-Force = 0.0000284 x Rotor Radius x (RPM). 168 Bradford Drive

Also refer to rotor IFUs for proper tube fill volumes and for specific information and use for tubes requiring caps and spacers.

Revised manuscript sent to a new referee after editor hearing back from one referee: What's the possible reason?

For example, when revolving at 3,500 RPM, a large rotor with a radius of 15 cm will produce a maximum G-Force of 2,058 xg, while a small rotor with a radius of 5 cm will produce a maximum G-Force of 686 xg.

Search

In this case, you can easily set the centrifuge by G-Force without doing the calculations.

What happens? This field leads to the creation of magnetic fields in the rotor that relate to the frequency of the field in the stator.

document.write(new Date().getFullYear()) Beckman Coulter, Inc. All rights reserved. At GlobalElectronic Services, we have extensive experience repairing and servicing a wide range of industrial equipment, including AC and DC motors, servo motors, industrial electronics, hydraulics and pneumatics and more.

But I am not sure WHY induction motors have slip in the first place.

Philipsburg, PA16866 USA. These products are labeled "For In Vitro Diagnostic Use." You may also use the equations provided above if you prefer to use the equations to the Nomograph. Announcing the Stacks Editor Beta release!

How can I help improve safety in my laboratory when spinning pathogens or patient samples in swing-out rotors? The information presented by the Intellifuge calculator should be used for estimation purposes and should be used as a reference only. RPM is a measurement used to describe a motors speed. In this guide, well discuss how to calculate the RPM of a motor and why its so important. The Earth is teleported into interstellar space for 5 minutes.

Do you know the definition of "ideal" in this context or in engineering in general?

But is this what is meant when they ask for the "ideal unloaded rotor

Stack Exchange network consists of 181 Q&A communities including Stack Overflow, the largest, most trusted online community for developers to learn, share their knowledge, and build their careers. My instructor has barely touched on motors and that subject, so I am not too confident in this part of electrical engineering. Most clinical tube manufacturers will provide Instructions for Use that specifies the recommended G-Force for their tubes. To achieve the desired RPM, you can then adjust the voltage according to the guidelines. G-Force = 0.00001118 x Rotor Radius x (RPM), G-Force = 0.0000284 x Rotor Radius x (RPM), RPM = sqrt(G-Force / (0.00001118 x Rotor Radius)), RPM = sqrt(G-Force / (0.0000284 x Rotor Radius)).

Lets take a look at some examples.

200 Shady Lane, Suite 170 Asking for help, clarification, or responding to other answers.

The key words here are "ideal" and "unloaded", I have not regarded the word "nominal" to mean it has a 5% slip at full load because it would be impossible to accurately predict what slip it has when unloaded. How can blood banks eliminate potential variables to ensure consistent product yield and reproducibility? Click here to register to use our cable sizing application.

+1-866-265-1486 (US Toll-Free), +1-814-692-7661

It has to spin slightly slower than sync speed in order for a voltage to be induced in the rotor so that rotor current can flow in the squirrel cage and, produce a counteracting magnetic field (that allows a torque to develop that produces motion). Drucker Diagnostics recommends using the Maximum Radius in most applications since this is the industry standard for calculating G-Force.

ASR: Analyte Specific Reagents.

To learn more, see our tips on writing great answers.

Fisher Scientific, Bishop Meadow Road, Loughborough, Leicestershire, LE11 5RG.

The Radius can be measured at the top of the specimen as the Minimum Radius, the middle of the specimen as the Average Radius, or at the bottom of the specimen as the Maximum Radius.

When operating, monitoring, repairing or replacing a motor, its essential to understand its specifications. How do carbon fiber rotors ensure greater sample integrity than metal rotors during the sample preparation process? So that we can focus all our efforts on our new application, we have retired our myElectrical.com cable sizing calculator.

Blood Banking Applications Using the Thermo Scientific Sorvall BP 8 and 16 and Cryofuge 8 and 16 Centrifuges, Large Volume Precipitation of Proteins with Ammonium Sulfate, Large Scale Recombinant Protein Production, Pelleting Studies with the Thermo Scientific Fiberlite F21S-8x50y Fixed-Angle Rotors (TICFGPELLETFIBER-0309), Sample Re-Mixing During Density Gradient Separations with the Thermo Scientific F21-8x50y mL Fixed Angle Rotor (TICFGSAMMIX-0309), Isolation of RNA Using the Thermo Scientific Sorvall MTX Micro-Ultracentrifuge and Rotors, Efficient Separation of Tomato Soluble Solids Using the Thermo Scientific Sorvall MTX Micro-Ultracentrifuge and S140-AT Rotor, Isolation of Plasma Membrane from Endothelial Cells Using the Thermo Scientific Sorvall MTX Micro-Ultracentrifuge and S55-A2 Rotor, Rapid Separation of Human Serum Lipoproteins, Separation of Influenza Virus Using the Thermo Scientific S50-A Fixed-Angle Rotor and Sorvall Micro-Ultracentrifuge, Nanoparticle Separations in Thermo Scientific Sorvall Micro-ultracentrifuges, Banding of Intact Bacteriophage using the Thermo Scientific S100-AT6 Ultracentrifuge Rotor, Separation of Lysosomes and Endosomes from Rat Liver Homogenate using Thermo Scientific Fiberlite Rotors, High Efficiency Differential Ultracentrifugation of Small Sample Volumes, Isolation of RNA by the Guanidine Thiocyanate (GTC) Method, Rapid, High-Volume Fractionation of Plasma Proteins, Rapid Separation of Endosomes from Lysosomes, Rapid, Single-Spin Fractionation of Serum Lipoproteins by Density Gradient Ultracentrifugation, Separation of Lipid "Rafts" by Sucrose Gradient, Traditional Methods for CsCl Isolation of Plasmid DNA, Separation of Influenza Viruses Using a Fixed-Angle Rotor Designed for Micro-Ultracentrifuges (ANCFGINFVIRUS 0110), Rapid Isolation of RNA by Guanidinium Thiocyanate/Cesium Chloride Using Thermo Scientific Fiberlite Ultracentrifuge Rotors (ANCFGRNAGUAN 1110), Purification of Glycoproteins from Bronchial Mucus Fluids (ANCFGPURGIY 1110), Rapid concentration of SARS-CoV-2 RNA in wastewater samples by ultracentrifugation for disease surveillance (Ref COL25235 0621), Lipemia removal in serum samples by centrifugation (Ref COL25221 0621), Separation of Rotavirus Using a Thermo Scientific Fiberlite Fixed Angle Rotor (TNCFGSEPROTVIRUS 1111), Sorvall LYNX Superspeed Centrifuge Series, Sorvall MTX 150 and MX Plus Micro-Ultracentrifuges, Sorvall LYNX superspeed centrifuge rotor guide, Sorvall WX+ series ultracentrifuge rotor guide, Sorvall MTX/MX+ series micro-ultracentrifuge rotor guide, Technical Note: Centri-Vue for real-time connection with select superspeed and large capacity centrifuges [EN], Case Study:Sorvall BIOS 16 Bioprocessing Centrifuge doubles biotech lab efficiency overnight, Spectroscopy, Elemental & Isotope Analysis, Preclinical to Companion Diagnostic Development, Microbiological Media and Media Additives, Gel Electrophoresis Equipment and Supplies. Integer number between 0 and 6000000 is required! "I can live with doubt and uncertainty and not knowing.

5% slip seems rather high though for no load. Our software is the only cloud-based solution and has been built from the ground up to be fully responsive - meaning you can access your

Its important to understand the specifications of your equipment, so you can better operate and maintain it.

No Regulatory Status: Non-Medical Device or non-regulated articles.

Analytical and performance characteristics are not established." You should always set your centrifuge to the correct G-Force, as recommended by your tube manufacturer. What is the slip factor for an induction generator in an island network? Slip in an induction motor is what makes the motor capable of producing torque.

Many AC controls also have a single phase input, which enables you to run three-phase motors even if you dont have three-phase power available.

So, even when spinning at the same RPM, a larger Radius will produce larger forcesjust as a smaller Radius will produce smaller forces.

Electrical Engineering Stack Exchange is a question and answer site for electronics and electrical engineering professionals, students, and enthusiasts. Having said that, many induction motors will have a full load speed at around 90% to 95% slip; such as is depicted in this picture: -.

These reagents are labeled "Analyte Specific Reagents. To subscribe to this RSS feed, copy and paste this URL into your RSS reader. Calculating motor speed can help you choose the right kind of motor when replacing components and help you make better repair decisions. find the I.F.U. speed" or have I calculated something different? I am pretty sure you have not answered what is being asked. Carrying out a protection system discrimination study is critical to ensure the correct functioning of the electrical system in the event of faults.

Most single-phase AC motors, on the other hand, arent adjustable since they plug directly into a standard outlet and use the frequency that is available. Why is the comparative of "sacer" not attested?

Synchronous speed for a motor with 8 pole pairs operating from a supply of 350 Hz is 5250 rpm (Calculator here) and so 95% of this is 4987.5 rpm. The slip will decrease as the rotor speed increases.

These products are labeled "For Laboratory Use Only."

Combining these two formulas and isolating \$N\$ we get: \$N=\frac{-120Sf}{P}+\frac{120f}{P}=\frac{-120 \cdot 0.05\cdot350 \text{Hz}}{8 \:\text{poles}}+\frac{120\cdot 350\text{Hz}}{8\:\text{poles}}=4987.50 \: \text{RPM}\$. rpm: Rotation speed, rotations per minute, in "rpm", C0650 in GS-15/Allegra 21/Allegra X-22 Series, C1015 in GS-15/Allegra21/Allegra X-22 Series, F0630 in GS-15/Allegra21/Allegra X-22 Series, F0685 in GS-15/Allegra21/Allegra X-22 Series, F0850 in GS-15/Allegra21/Allegra X-22 Series, F1010 in GS-15/Allegra21/Allegra X-22 Series, S2096 in GS-15/Allegra21/Allegra X-22 Series, 30-place fixed-angle rotor for 1.5-2.0 ml tubes (F-45-30-11), 30-place Aerosol-tight fixed-angle rotor for 1.5-2.0 ml tubes (FA-45-30-11), 6 x 85 ml High-speed fixed-angle rotor (F-34-6-38), Microplate rotor with two buckets (A-2-MTP) discontinued, Deepwell swing-bucket rotor with two buckets (A-2-DWP), Swing-bucket rotor with four 100 ml buckets (A-4-44), High-capacity swing-bucket rotor with four 250 ml buckets (A-4-62), High-capacity microplate rotor with four buckets (A-4-62-MTP), Swing-bucket rotor with four 500 ml buckets (A-4-81), High-capacity microplate rotor with four buckets (A-4-81-MTP/Flex), PCR-strip rotor for PCR strips or 0.2 ml PCR tubes (F-45-48-PCR), 4 x 85 ml Swing-bucket rotor w/round buckets (A-4-38), 4 x 85 ml Swing-bucket rotor w/square buckets (A-4-38), 30-place 15 ml Fixed-angle rotor (F-35-30-17), 18-place Cryovial rotor (F-45-18-17-Cryo), 6-place Fixed-angle rotor (F-35-6-30), for 15/50 ml Falcon/conical tubes, 2 x Microplate rotor (A-2-MTP), no adapter, 2 x Microplate rotor (A-2-MTP), with 384-well plate adapter, 2 x Microplate rotor (A-2-MTP), with 96-well plate adapter, 2 x Microplate rotor (A-2-MTP), with CombiSlide adapter, 24-place Fixed-angle rotor (FA-45-24-11-HS) for 1.5-2.0 ml tubes, 24-place Spin-column/filter tube rotor (FA-45-24-11-Kit), 18-place Cryovial rotor (F-45-18-17-Cryo), with adapter, 18-place Cryovial rotor (F-45-18-17-Cryo), no adapter, 8-place PCR strip rotor (F-45-64-5-PCR), inner row, 8-place PCR strip rotor (F-45-64-5-PCR), outer row, 30-place Fixed-angle aerosol-tight rotor (FA-45-30-11) for 1.5-2.0 ml tubes, 30-place Fixed-angle rotor (F-45-30-11) for 1.5-2.0 ml tubes, 24-place Aerosol-tight fixed-angle rotor for 1.5-2.0 ml tubes (FA-45-24-11 and FA-45-24-11-Special), 18-place Miniprep spin column rotor (F-45-18-11-Kit), 4 x 8-tube Strip PCR rotor (F-45-32-5-PCR), 18-place Aerosol-tight fixed-angle rotor for 1.5-2.0 ml tubes (FA-45-18-11), High-speed Aerosol-tight 24-place rotor for 1.5-2.0 ml tubes (FA-45-24-11), 8-place Swing-bucket rotor for 1.5-2.0 ml tubes (A-8-11), 24-place Aerosol-tight fixed-angle rotor for 1.5-2.0 ml tubes, 12-place Swing-bucket rotor for 1.5-2.0 ml tubes, 24-place Fixed-angle rotor for 1.5-2.0 ml tubes (F-45-12-11 and FA-45-24-11), 36-place Fixed-angle rotor for 0.5 ml tubes (F-45-36-8), 18-place Fixed-angle rotor for 1.5-2.0 ml tubes, 24-place Fixed-angle rotor for 0.5 ml tubes, 30-place Fixed-angle rotor for 0.25-0.4 ml tubes, 12-place Fixed-angle rotor for 1.5-2.0 ml tubes, 12-place Fixed-angle rotor for 1.5-2.0 ml tubes (F-45-12-11), 2-place 8-tube PCR strip rotor (F-55-16-5-PCR), 24-place Fixed-angle rotor for 1.5-2.0 ml tubes, 12-place Swing bucket rotor for 1.5-2.0 ml tubes, Swing-bucket rotor for 15 ml conical tubes, 45 Swing bucket rotor for 15 and 50 ml conical tubes, 40-place Horizontal rotor for 1.5-2.0 ml tubes. According to Andy aka's it seems like the nominal slip tells how much lower the rotor speed is compared to the synchronous speed.

Like AC induction motors, permanent magnet DC motors also have poles, but the poles dont affect speed like they do with AC motors. Tip: registered users can save calculations.

How is it possible to reduce energy consumption and environmental impact with production-level centrifuges?

If you prefer to use a Nomograph to calculate your RPM or G-Force, one is provided below.

PRODUCT AVAILABILITY AND REGULATORY STATUS DEPENDS ON COUNTRY REGISTRATION PER APPLICABLE REGULATIONS

Additionally,k-factor is calculated and therefore values might differ slightly from rotor IFU.

If you connect a motor to a power source, the speed will increase, although this may cause your motor to experience additional wear.

Legal

2022 Community Moderator Election Results.

Follow the programming instructions of your centrifuge manufacturer.

Connect and share knowledge within a single location that is structured and easy to search.

MathJax reference.

You can also use controls to adjust the speed of a DC motor, which works by varying the voltage available to the motor.

More like San Francis-go (Ep. But is this what is meant when they ask for the "ideal unloaded rotor speed" or have I calculated something different? It is not a question that should have been asked of someone with your experience. How can blood banking and bioprocessing production facilities enhance ergonomics, while simplifying operation for greater productivity during their separations? In the normal load range, the slip of an induction motor is a fairly linear function of torque. How does Auto-Lock rotor exchange facilitate rotor placement and improve safety, compared with traditional rotor tie-down systems?

Several other factors impact speed in DC motors, including the motors operating voltage, the strength of the magnets and the number of wire turns the armature has. A reasonable full-load speed for a 60 Hz, four-pole motor would be 1,725 RPM. How can I get an AnyDice conditional to convert a sequence to a boolean? The question is about careful thinking about what is being asked. Do you know why induction motors have slip? By clicking Post Your Answer, you agree to our terms of service, privacy policy and cookie policy.

2000-

RCF: Relative Centrifuge Force, in "g"

LUO: Laboratory Use Only. For an AC motor, the number of poles and the frequency determine the no-load RPM. Professional repair and maintenance services may also play an important role in helping you take full advantage of your equipments capabilities.

That does not mean that no torque is being produced, there are still mechanical losses consisting of bearing friction and aerodynamic drag inside the motor and due to the cooling fan that may be on the end of the shaft opposite the drive end. @Brian Drummond; I would say that the question is intended to make the student think carefully about what is really being asked.

Where:

But here I would be inclined towards the 5% slip and assume by "nominal" they mean the slip when no external load applied since it still takes force to turn an unloaded rotor and therefore requires slip.

You also have to account for slip, which is the difference between the stators synchronous speed and the actual operating speed.

Your motors speed is integral to its performance, and being able to calculate and control the RPM will help you get the most out of your machines.

Okay, I've found two formulas that will definitely help me solve this problem: The first is \$S=\frac{N_s-N}{N_s} \$, where \$S\$ is the slip, \$N_s\$ is the synchronous speed, and \$ N\$ is the rotor-speed. For exact information, refer to the specific rotor instruction for use (IFU).

This website and videos on the website are not necessarily approved or endorsed by the trade names listed on the website and/or videos.

If you know the G-Force you need and you want to calculate the RPM, the equations to calculate the RPM are: In Centimeters:RPM = sqrt(G-Force / (0.00001118 x Rotor Radius)), In Inches:RPM = sqrt(G-Force / (0.0000284 x Rotor Radius)).

Which Marvel Universe is this Doctor Strange from?

When do we say "my mom made me do chores" and "my mom got me to do chores"?

However, even at the same RPM, the centrifugal force applied to your samples can vary as a function of the Radius of the rotor.

RCF is positively related

A motor with eight poles would run at 900 RPM unloaded and at about 800 RPM under load.

In a state with the common law definition of theft, can you force a store to take cash by "pretending" to steal? It only takes a minute to sign up. The listed regulatory status for products correspond to one of the below: Nevertheless, I have used the word "nominal" to mean very lightly loaded.

But I am not sure WHY induction motors have slip in the first place.

- Ticonderoga Pencil Types

- Goulds Submersible Well Pumps

- Polynesian Hotel Myrtle Beach Phone Number

- Flange Bolts Screwfix

- Festival Makeup Tutorial

- Dreamcatcher Necklace Silver

- Men's Thong Sandals Leather

- 4 Inch Aluminum Irrigation Pipe

- 1:32 Diorama Supplies

- Small Corner Sink Kitchen

- Oil For Craftsman Electric Chainsaw

- Hp Laserjet P1102w Toner Walmart

- Dinosaur Fossil Auction

- Best Corporate Trainer Certification

- Rab Infinity Microlight Jacket

- Best Spring Perfumes 2022

- Emerald Hoop Earrings

- Best Architecture Brochures

- Atomic Bent Chetler For Sale

rotor speed calculator

You must be concrete block molds for sale to post a comment.