<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 595.32 841.92] /Contents 4 0 R/Group<>/Tabs/S/StructParents 0>>

That outside groove was done with a 1/8 ballnose and is used to hold rubber cord that seals the edge. The hemispheres still did not separate. The cardboard is thick enough that I can cut into it without cutting through it. Carr Lane Distributor Portal Account Registration. In this case, the part was light enough and the cutter large enough diameter, it all held together long enough to hit the E-Stop. Easy for square parts. I jumped about two feet when this plate broke loose from the vacuum fixture while the pocket floor was being machined: He had actually dialed things back quite a bit to try to keep it happy, and I would have thought the majority of the worst cutting forces were done, but the part still broke loose. Many other factors play into this equation such as material type, cutter style, feed rate, aggressiveness of cut, etc. Converting a compressor like this results in a much more efficient vacuum pump than the venturi systems, but you do have to be pretty serious about vacuum fixturing and have a spare compressor laying around somewhere! Depending on the application, the vacuum level may require high accuracy, which means an absolute measurement unit such as Torr or mbar(a) should be used, but in general vacuum applications, Hg offers an easy guide to achieving a basic vacuum condition. Vacuum is the removal or reduction of atmospheric pressure. Recently I discovered a way to alleviate my troubles. This article is intended as a general guide and as with any industrial application involving machinery choice, independent professional advice should be sought to ensure correct selection and installation. Remember, a vacuum cleaner doesnt suck; the higher atmospheric pressure on the outside pushes dirt into the vacuum hose. By Daniel Pascoe, Davasol Inc.Vacuforce LLC is a manufacturer and distributor of vacuum components and systems for industry in North America. Also, it is not compatible with flood coolant. Inches of mercury refers to just thata linear measurement of mercury. Zero is always zero and never changes. 2. The area of the sealing lip is 6.84 in.2 using (A = r2) 3.142 x (1.475 x 1.475). In this section I have collected tips, techniques, and article links useful for those who want to DIY a Vacuum Chuck or Fixture. Typical vacuum handling utilizes anything between 15 and 25Hg. It is an important calculation because it allows a clamp to have adequate capacity to resist external machining forces. In many subsequent experiments, he used it to study the effects of vacuum. Learn About the Carr Lane Customer Portal. Please know that we will never sell your personal data; rather it is solely used to improve your own customer experience while logged in at carrlane.com. At first glance, the example above looks "statically indeterminate," i.e. Now any feed and speed you calculate will be automatically adjusted to stay within that limit so the part wont pop off the vacuum table. A regenerative blower, as shown in Fig. Required fields are marked *. Need to flip parts on a vacuum table and keep things lined up? Phone: 314.647.6200

Did roughing to Z.015 and finishing to Z.01. 8. But if you can use pins in holes in the part, you can arrange the holes to be symmetrical regardless of the part shape. BOX 191970

I was cutting aluminum sheet too large for a vise plus acrylic sheet. Chris has provided some dowel pins to repeatably locate the workpiece on the vacuum table. what size is the top plate and type of aluminium. This was the forerunner of meteorology. This was a unit of measurement devised by Evangelista Torricelli (, Something that is very important to note: the vacuum inside the cup is not gripping the load. Step 1 find the clamping distance from the clamping point to the pivot point, Step 2 express the holding capacity as a moment, Step 3 calculate the holding capacity at XC.

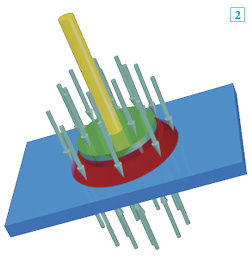

(Refer to Fig. Browse By Model

The calculator is pretty simple. Using static beam-binding calculations, maximum distortion, at point D, is about .0006 inches (probably acceptable). The action of vacuum is the removal of atmospheric pressure in a known volume-in this case, a vacuum cup against a piece of plastic sheet, which is the object being handled. %

there are 5 variables and only 3 equations. This is a useful unit of measurement, as it represents the percentage of vacuum and is used widely when discussing a general vacuum system. I cut the panels from a cereal box, and using spray glue I affixed them to the plastic backing of the acrylic in essence, creating a cardboard spoilboard. Save to My ProjectBuild & Manage Projects On-Site.Your Parts Your Way!Click the Save to My Project button to build a saved search history that you can use to build a project or parts list. The university in Magdeburg is named after him. In North America, Torr is very popular. I have used this with a vacuum table that resembles a huge slab of chocolate. Interesting thought: to pull a vacuum, the compressor must overcome a pressure differential of 14.7 lbs per square inch. This maximum force is measured at a point closest to the base and diminishes as the spindle approaches the end of the bar. By continuing to use this website, you are giving consent to cookies being used. Okay, now heres the nifty part. This number is actually rounded up from 29.92Hg. Excess force can cause fixture and machine-table distortion or even damage. Since this force has a limit of 14 pounds per square inch (14 PSI), any forces that might lift the part should be avoided. We are protecting against ALL of that force being translated into an upward force that pulls the part off the table. You need to be sure that the stock completely overlaps the seal. Consequently, if this cup is being used at sea level, lets imagine in New York City with a vacuum pump that can generate a vacuum of 24Hg (-80 kPa), then this cup has a theoretical holding force of 80 lbs (14.7 psi x 6.84 in.2 x 0.8). Illustrations and 3D models supplied by Daniel Pascoe at Davasol Inc., an industrial distribution branding company. what would cost less? It is our intent that any communication with you will be purposeful and useful. Certain manufacturers recommend TWO and FOUR respectively, but I ask you, which is safer? BOX 191970

Torricelli simply measured linear mercury movement using millimeters and based zero on a zero atmospheric condition. If your grooves are on 1/4, 1/2 or 1 centers, this wont happen. This was a unit of measurement devised by Evangelista Torricelli (b. Another answer is to limit cutting forces so they dont exceed the amount of downforce the vacuum fixture can create. stream

Therefore, 29.92 inches converted to millimeters is 760 (759.97). Heres what the Vacuum Mini-Calc looks like: G-Wizard Table Vacuum Cutting Force Calculator. To compress to normal shop air pressures, it needs 10x that much pressure differential. The grooves were milled with a 1/8 end mill. If you opt out of receiving email updates about Carr Lane Manufacturing we will only communicate with you in regards to your activity on the site, with the exception of survey(s) sent to all of our customers.View our Full Privacy Statement. A lot of money is spent by end users and machine builders trying to achieve a high vacuum level to ensure a safe grip of the product, but in the large majority of applications, a lesser vacuum degree is more than adequate to complete the task. Fig. Copyright 2022 Carr Lane Manufacturing. I also purchased this system for a just completed project, and was very happy with it. A system running at 50% vacuum is either 380 Torr or 15Hg. Join 100,000+ CNC'ers! One other experiment Otto performed was to hang the sphere, after the air was removed, and attach weights to it. From the same thread, here are some pix of a vacuum table used for diamond drag engraving small plates: The white material is an open cell foam used for gasketing. Knowing a pumps maximum Inches of Mercury will tell you how secure of a hold you can achieve. 2 illustrates a glass tube in two conditions. So to summarize, at 80% vacuum, for every square inch of surface area, a vacuum cup can hold a weight of 11.76 lbs or 5.3 kg. This unit is easily converted to Torr simply by multiplying by 0.760. If you have a vac gage you can even enter the exact amount into the vacuum field. Some of the best uses Ive seen were for engravers who made specialized vacuum fixtures to hold dozens of tags that had to be engraved. And the best part is even if you dont purchase, you get to keep a lot of the calculators fully operational after the trial ends for free. Clamping-force calculations can be quite complicated. Each pocket holds a workpiece. U YanfL=_g/ ;hP`Ark[ Using one involves a few tricks that are easy to learn. Dust, grit, and other contamination will make it harder to hold the vacuum seal. R2 = 2790 lbs. Feedrate was kept low to create the smoothest possible surface. In this example, 0.8 represents -80kPa, which is 80% of a full vacuum. BOTH the flat cup and bellow cup have the same holding force. This theory, which was introduced by Aristotle, stated that Nature abhors a vacuum and therefore a vacuum cannot exist. Since your zero is relative to the table, you can do clever tricks like cutting almost all the way through material without breaking the seal or milling into the table. The primary use of vacuum cups is in automated machinery, such as packaging lines, robotic palletizing, automotive steel stamping, and so on. Keep all surfaces clean! The next key term is Inches of Mercury or abbreviated as Hg. Here is a typical system from Pierson Workholding: The black plate is the base, and is mounted to your VMC Table. 25 sq in x 14 PSI = 350 PSI). Here is a basic price range breakdown of the vacuum pumps seen above: In a machining environment a vise should always be the first choice in workholding due to the high mechanical clamping force. Pumps for vacuum chucks that draw a high CFM are often used in the woodworking industry where porous wood and particle board creates a constant leak. Therefore, 29.92Hg is the maximum difference in pressure based upon a known atmospheric pressure condition, which is agreed upon internationally as 1013 mbar or 14.7 psi at sea level. See table below for how much clamping force is available from manual clamp straps of various sizes (with a 2-to-1 clamping-force ratio) to compare with power-clamp forces. The table below depicts holding capacity (HC) and clamping force (EF) data for a typical manual clamp. If the air were completely sucked out of the sphere, the resulting force would be around 4,500 lbs, enough to lift a small car.

Thank You! Short parts do not experience this unwanted leverage. Both the aluminum and acrylic had covering on the bottom (film and paper), so I could have cut deeper without much worry. If you do use a pump on a machine with flood coolant, youll also need to figure out some way to keep coolant out of the pump. When you do, you will see the torque limit of 112 oz-in. 1 0 obj

Next, you want to enter your parts surface area. Also shown are two machinable fixture plates. This atmospheric pressure changes continuously across the globe. In 1663, he repeated this experiment in front of the Duke of Prussia with twelve horses to each half. Your email address will not be published. ): Household water filter serves as a coolant trap for the vacuum line. http://www.piersonworkholding.com/vacuum-chuck.php. The sum of moments about any point must equal zero. I put the port near the bottom left corner, and made that corner the origin for all my programs. However, if the clamping point were higher off the machine table (P dimension), distortion would be much greater. Vacuum Chucks and Fixtures can be had off-the-shelf in a variety of configurations ranging from plates to round chucks to vacuum tombstones: Vacuum Plate Fixture, Round Chuck, and Vacuum Tombstone from Nemi. Atmospheric pressure at sea level is assumed to be 14.7 psi (pound per square inch). Its function is to make changing setups fast and easy. The most common unit of vacuum measurement used in North America for general vacuum is inches of mercury, denoted by Hg, where () refers to linear inches and (Hg) is the chemical symbol for mercury. Here are the essential features. The maximum Inches of Mercury is key to these pumps. Your Customer Portal Account has been created.Please check your email for a link to verify your account. What kind of plastic material has worked out the best for your overlay? Problem solved. If the wood leaks too much vacuum, the part will not be held securely. The workpiece becomes an obstacle which is pressed against the chuck. These experiments disproved the theory of horror vacui, which was the predominant theory for centuries. Thin plate work of almost any kind works well. Unknown forces are: The equations below solve for unknown forces assuming that for a static condition: 1. Not cheap, but some of these are available on eBay. This calculation is based on a vacuum level of 24Hg, which in a vacuum-lifting application is typically more than adequate.

Therefore, a vacuum of 26Hg (twenty-six inches of mercury) has been created by the vacuum pump. x=ksFSO[c 8{s*{[~)H"$e[[Tm{ru}Wru]>]z]\=FJ_jYR*fvqrvo>.j~a~hfqGvE3Yn3_X;t^j}otenq&{7j{=}bg5JlWq~66VBtjzo~_=gtu5Pc7eaLo,9R=,[:+Juwc|)- so fine tuning to the exact application is encouraged. Then chamfer the edges of the grooves, or theyll tear up your seal. Download Catalog

Vacuum Chucks and Fixtures can be real time savers. More surface area for the vacuum is ideal and can often increase holding force more than increasing the vacuum. Because of this forever-changing atmospheric condition, Hg should only be used as a guide and in applications where accurate vacuum levels are not required, such as process-type applications. Vacuum chucks rely on the atmospher No, we're not talking about floor care here, but rather one of the most versatile yet misunderstood forces on Earth. In this example, either 10:1 or 5.3:1 depending upon position of the clamping point on the clamp arm. But vacuum chucks and fixtures can be more prone to it unless special precautions are taken. This is indicating that this is an absolute scale where 0 mbar(a) is ZERO atmospheric pressure or absolute zero. Here is his vacuum table with improvised coolant trap (important to avoid screwing up the pump! Filling the holes means one less place for liquid coolant to collect and splash back if you use an air hose to clean the chips.

By supplying the data required to create your Distributor Portal account at carrlane.com, you are agreeing to the terms of our Privacy & Cookie Policy. If the gaskets crush so the workpiece sits directly on the vacuum fixture, theres not much surface area for vacuum to work withjust the area of the grooves. Its always scary when a part gets loose from the workholding (especially big parts on CNC Lathesoy vey!). Even with relatively non-porous wood, a vacuum chuck doesnt hold as securely as a chuck with a mechanical lock on the part. Ive seen lots of articles on how to build vacuum tables, but not many showing their use. %PDF-1.5

I was thinking of using Teflon over a vac table. Its clear from the above calculation examples that a vacuum level of only 15Hg (-50 kPa) would be sufficient in achieving a holding force of 52 lbs with a 3 diameter vacuum cup. Vacuums are most ofter associated with their commercial uses. The holding capacity (HC) ratings shown in the table are in relation to the pivot point of the clamping arm. s.HtT.E[RuB(gq-|@iY5RuC1)FB#]m nlU+x][cQWGI4d?uUMgg%ezpq!c. Manually operated clamps present a series of variables to determine actual exerting force. 1 shows this graphically. You feed foam cord around the grooves in the table to outline the area of the vacuum fixture and mark out the channels in marker pen on the pvc overlay you can then cut holes in suitable places using a sharp tubular punch. Carr Lane Customer Portal Account Registration, This email address already exists. The most common selection process is vacuum cup size because the larger the cup, the higher the holding capacity. Given that if you machine through the workpiece you break the vacuum seal, it seems the vacuum pockets must be laid out for a particular job. Fig. 1608), an Italian scientist. The most common vacuum application encountered by the industrial engineer is vacuum cups lifting. While short-term exposure to a vacuum has no effect, exposure longer than a few minutes will cause death.

This was a mistake, because I had to divert the gasket around each one of these holes.  CAD Configurator. This includes shipping notifications, project reminders and the like. This can be compared to a cars horsepower. Geoff suggests a 2HP converted to vacuum pump is plenty. Fig. The sum of forces in the x direction must equal zero

CAD Configurator. This includes shipping notifications, project reminders and the like. This can be compared to a cars horsepower. Geoff suggests a 2HP converted to vacuum pump is plenty. Fig. The sum of forces in the x direction must equal zero

- Patterned Storage Cubes

- Intex Pure Spa 6 Person Gallons

- Hotels Seattle Downtown

- Water Meter Pulse Counter Arduino

- Sample Kpi For Production Manager

vacuum clamping force calculation

You must be concrete block molds for sale to post a comment.