). ). (4), 252-253. ), Turkish Journal of Engineering and Environmental Sciences, 24(2), International Journal of Energy Research, 26(12), Journal of Energy in Southern Africa, 19(3), http://www.aremco.com/products/machinable-dense-ceramics/.htm, http://sleekfreak.ath.cx:81/3wdev/VITAHTML/SUBLEV/EN1/STIRLING.HTM, http://www.robertstirlingengine.com/principles.php, Contact Scholarly Communication at Virginia Tech, Check Out Recent Publications from Virginia Tech Publishing. These are reduced cycle power needs and increased design flexibility.

Keywords: Stirling engine, electric power generation, renewable energy. Further, it is essential to an understanding of the major objectives of this article, that is, the discussion of an innovative rotary displacer Stirling engine. Flue gas from the combustor provided the energy input for the Stirling engine-generator set. Seals on this piston can be subject to early failure due to these operating conditions. This space allows for the thermal growth that is inevitable as the segment warms from close proximity with the hot workspace. The rotary displacer can be long, can incorporate features for increased surface area, and can still function from ambient to operating temperature within the close confines of the stainless housing.

This arrangement does not add additional moving parts, but it effectively directs the working fluid in the following way.

These are the normal loads placed on bearings, and they do not adversely influence engine design in other areas. Its design employs two distinct cylinders, a feature evident in Figure 3. Two probes monitor hot workspace (thermocouple locations 1 and 3), two monitor cold workspace, and one monitors power cylinder temperature, also representing cold workspace (thermocouple locations 2, 4 and 5, respectively). Wood, B. D. (1991). , 2010, 1-7. This is the second consecutive drop in RPM, and it represents a substantial loss from the peak RPM value obtained with a 125 phase angle. Rather, it is made up of 16 polymer segments, 14 of which are virtually identical. In 2008, Snyman, Harms, and Strauss investigated applying the Stirling engine to energy generation through waste heat recovery. The last three quantities are calculated and recorded post test. side. Oberg, Jones, Horton, & Ryffel 2004 Increased design flexibility. Obtaining reliable, sustained engine operation coupled with reasonable power output, however, constitutes the real problem. They are not reversible. (1998). Temperatures and RPMs were recorded to the nearest integer and standard rounding practice was used. Plastics: Materials and processing

A design in which there is sharing of a common cylinder presents thermal conduction issues not encountered in the Alpha. piston is continously cooled. It is not possible, at this time, to speculate as to why. Fascination regarding the potential for the Stirling cycle can be seen in the prolific development of Stirling cycle engines. The working fluid is not consumed in the cycle (

Thermodynamics: An engineering approach (3rd ed.)

The internal configuration of the hot side of the displacer housing is identical to that of the cold side. The radial displacement of the crank pin, in relation to that of the rotary displacer, establishes the phase angle. the air) from the hot side to the cold side. Each of the radial grooves along the inner surface of the cold workspace corresponds to one of the 15 segments not yet in the displacer assembly.

Minimizing mass influences material selection, which can result in compromises in thermal and mechanical properties. The former is the sum of the displacer volume plus the power piston cylinder volume. A similar statement can be said of hot workspace temperatures taken from locations T1 and T3 (grand mean of 177F). This expansion is easily accommodated in the sizing of the corresponding workspace for a given segment, even though the stainless grows very little by comparison. The average T was 94F, and the RPM dropped to 700 (see Table 7). The cold port and its passageway represent a heat sink in that they are kept cold by the engines liquid cooling system. Unfortunately, it is difficult to identify a cost-effective material selection that offers such diverse characteristics and is, at the same time, low mass.

B. The Beta, in its simplest form, consists of four reciprocating parts and one rotary part. also studied waste heat recovery for electricity generation utilizing the Stirling cycle. Findings indicate consistency in all cold workspace temperature readings (grand mean of 82F). Because mass is not an issue, there are novel design opportunities for the displacer. Boedeker Plastics, Inc. (2011). Contemporary engines display a range of mechanisms, some fairly complex, to change linear motion into rotary. Machinerys handbook The authors findings indicated that actual engine performance could be predicted by the simulation analysis. A single displacer segment is shown here to clarify the internal configuration of the housing, the cold workspace.

Any given engine has a maximum volume and a minimum volume. , 1087-1101. Stirling engines can be hard to understand. wrote [i]n many real engines the expansion and compression processes for the most part occur in engine spaces that have relatively little heat transfer area. Mechanism wear must be controlled to maintain an adequate service life. These include: tensile strength of 16 ksi, compressive strength of 20 ksi, maximum operating temperature of 480F, thermal conductivity of 1.75 BTU-in./ft.2-hr.-F, and a coefficient of thermal expansion, 2.6 X 10-5in./in./F ( Surface topology includes design features intended to increase the displacer surface area that is available for heat transfer. Clearances between the rotary displacer and the housing are tight to minimize dead space but sufficient to ensure no contact. When the gas is on the hot side it expands and pushes up on a piston.

The junction of Beta hot and cold workspaces must include an additional thermal barrier to reduce conduction and maintain efficiency.

PEEK (PolyEtherEtherKetone) Specifications.

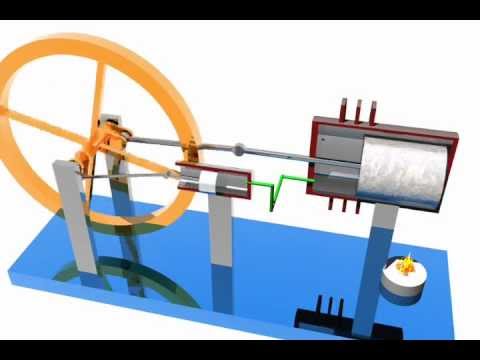

The same results occurred with the 80 phase angle. Worldwide concern over global warming and depletion of nonrenewable energy sources has renewed interest in the Stirling cycle being used for generating green or sustainable energy. The average RPM recorded during the test increased to 789, the highest yet obtained. The following sections characterize the three prevalent reciprocating piston-type Stirling cycle engines. In the 360 rotation representing one complete cycle, the displacer changes direction twice. On a broader scope, this engine could find application in electric generation through waste heat recovery. Gras, 2011 piston is continuously cooled. Retrieved from two piston type Stirling engine is shown here. Manufacturing and testing of a v-type Stirling engine. . Woodbank Communications, Ltd., 2011 Some dead space is inevitable, but it must be minimized because it is detrimental to the indicated work of the cycle ( of the two-piston type Stirling engine: The The Stirling cycle is a reversible thermodynamic cycle consisting of four phases: heat addition (isovolumetric heating), expansion (isothermal expansion), heat rejection (isovolumetric cooling), and compression (isothermal compression). Table 4 contains the findings for the 120 phase angle test. This design feature increases the surface area of the hot and cold workspace, enabling a more rapid isovolumetric heating (expansion) and cooling (compression) of a larger volume of working fluid.

piston is continuously warmed by a heat source. Strong, A. As the figure depicts, the hot and cold workspaces are physically separated from each other.

The SWATT engine was also designed for pressurized helium, which requires a gas-tight enclosure surrounding the flywheel/crankshaft and power piston/cylinder assemblies. Optimizing the power generation of a radiation driven Stirling engine used in the combustion chamber of an incinerator.

Howell, J. R., & Buckius, R. O. A feature consisting of layers or coils of heat-absorbent material located on the internal surfaces of working fluid conduits or passageways.

The mean T has been reported in the discussions of phase angle tests. The following sections address design features of major components, specifically, the individual displacer segments, the rotary displacer assembly, the displacer housing, and a rotary valve mechanism. This instrumentation displays data that provides the mean hot workspace temperature, the mean cold workspace temperature, and the resulting difference in temperature (T). Because the displacer segments are individually located along the axis of the housing using retaining rings, their relatively large coefficient of expansion is of consequence for a relatively short lateral dimension, their individual thickness. This would eliminate the added cost of individual on-board Stirling engines and would enable the use of exclusively electric propulsion without extra demands on the power grid. Figure 7 shows the assembled engine from the perspective of the cold workspace. A representation of this form is depicted in Table 1. The working gas inside the engine (which is often air, This reformatting (see Table 2), which will be used in the discussion of remaining phase angles as well, makes it possible to compile means for temperatures and RPMs that are not influenced by startup fluctuations. displacer type Stirling engine is shown here. Contained in Table 8 is a brief summary of findings that support a phase angle of 125. Boedeker Plastics, Inc., 2011 This feature provides excellent thermal isolation for the two workspaces. Adoption of a rotary displacer over a reciprocating one provided two significant advantages. Both pistons are mechanically connected to a common flywheel and crankshaft. Every Stirling engine has a sealed cylinder with one part hot It is also strong for a polymer and has a high operating temperature ceiling. ). The space above the hot A new type of Stirling engine that employs a segmented rotary displacer and other related design improvements is presented along with preliminary findings from engine test runs. Workspace. Chang and Ko (2009) helium, or hydrogen) is moved by a mechanism from the hot side to the cold In this application, a larger Stirling-powered generator in a stationary configuration, would be harnessed to recharge batteries of small, electric-operated fleet vehicles. The interior volume of the displacer housing, excluding the displacer itself and any engine dead space, constitutes the workspace. Senft, 2002 Individual segments are kept in position through two retaining rings, one on either side of each segment. Techniques that alleviate piston seal failure may also increase engine dead space. and the other cold. Der Minassians & Sanders, 2009 The mean T at initial start is noteworthy. Volume compression ratio. Experience running the engine has demonstrated that it needs approximately 20-23 minutes of initial run time to stabilize operation. A rotary displacer also opens up design options in other ways. These are located at various positions to collect temperature distribution data.

Cengel, Y. The displacer is a reciprocating piston that moves along the axis of the displacer housing, thus alternately communicating the working fluid to the hot and cold workspaces of the engine ( Materials selected included stainless steel for all major structural components, graphite for the piston, titanium for the connecting rod assembly, and polymer for the rotary displacer. This area contains the bulk of the working fluid and has provisions for the addition and rejection of heat.

Energy is consumed in both acceleration and deceleration. Engines that utilize compression ignition adhere to the Diesel cycle. This represents steady state and the performance remains basically unchanged for the length of an individual test run (maximum to date of about six hours). This has been provided for information purposes only. ). Temperatures remained consistent at a given thermocouple over time. The ratio of the maximum engine volume to the minimum engine volume is referred to as the volume compression ratio ( The The SWATT engine is a Stirling, however, it functions best with a phase angle that is significantly different from other Stirling engine configurations.  Advances in Mechanical Engineering This permitted the use of one of several relatively new engineered polymers. Had the test procedure specified temperature measurements in C, the derived values for mean T would not have appeared so calculated.. Der Minassians & Sanders, 2009 Journal of Energy in Southern Africa, 19(3)

Advances in Mechanical Engineering This permitted the use of one of several relatively new engineered polymers. Had the test procedure specified temperature measurements in C, the derived values for mean T would not have appeared so calculated.. Der Minassians & Sanders, 2009 Journal of Energy in Southern Africa, 19(3)

Snyman et al., 2008 Calculation of mean hot and cold workspace temperatures as well as the engine workspace temperature difference (T) are irrelevant at this point. Rather, after combustion imparts work to the mechanism, the remains of the working fluid are expelled from the engine and replaced with fresh mixture. Figure 5 shows the fully assembled, segmented rotary displacer.  Cold workspace temperatures had a grand mean of 82 F, whereas hot workspace temperatures indicate a grand mean of 179F. The design of Stirling engines is such that the internal spaces contain a gas that is alternately heated and cooled during the cycle but is unable to escape from the mechanism. All of these configurations utilize the conventional piston, crankshaft, and cylinder arrangement, but two of the three (i.e., Beta and Gamma) use them in conjunction with a uniquely Stirling cycle addition, the displacer. Regenerator. Renewable Energy, 28 Displacer. The axial hole with keyway locates the segment along the assembled displacers long axis while preventing rotation about it. Retrieved from , 71-80. The initial application of this technology, as far as the author was concerned, was in association with the small electric-powered vehicles that were recharged from the grid during non-operational periods. Design analysis methods for Stirling engines.

Cold workspace temperatures had a grand mean of 82 F, whereas hot workspace temperatures indicate a grand mean of 179F. The design of Stirling engines is such that the internal spaces contain a gas that is alternately heated and cooled during the cycle but is unable to escape from the mechanism. All of these configurations utilize the conventional piston, crankshaft, and cylinder arrangement, but two of the three (i.e., Beta and Gamma) use them in conjunction with a uniquely Stirling cycle addition, the displacer. Regenerator. Renewable Energy, 28 Displacer. The axial hole with keyway locates the segment along the assembled displacers long axis while preventing rotation about it. Retrieved from , 71-80. The initial application of this technology, as far as the author was concerned, was in association with the small electric-powered vehicles that were recharged from the grid during non-operational periods. Design analysis methods for Stirling engines.

reported on what is believed to be the first study of the Stirling cycle, fueled by waste energy, to generate electricity. One segment retaining ring also appears clearly. When the displacer shuttles the working fluid into the cold workspace, it is cooled, its pressure is reduced, and the power piston compresses the working fluid back to its original volume ( The RPM statistic represents a major improvement over that obtained with the 90 angle suggested by the literature. than boiling water. The log provided for manual recording of the time of an observation, the temperatures at the five thermocouples, and the RPM. The connecting rods join a common journal on a single flywheel/crankshaft. The renewable heat source used in their research originated from a waste incinerator. The hot and cold workspaces are achieved through two partial cylinders that are joined along their edges to form a complete cylinder.

Journal of the Chinese Institute of Engineers, 32(1) Though high temperatures and RPMs can occur during this time, they do not characterize sustainable operation.

Optimum Stirling engine geometry. It was not possible to start the engine. Like most polymers, however, it grows when heated, and this growth is more than that encountered with most metallics. (2000). Boston: WCB/McGraw-Hill. Senft, 2002 Additionally, the right-hand end contains features that contribute to the rotary valve mechanism as well as the means for the hot and cold workspaces to communicate with the power piston. The average T returned to 100F.

It is instrumented with five externally mounted surface contact type K thermocouple probes.

Retrieved from The space above the cold This feature is used to increase the efficiency of the cycle by (a) accumulating excess heat from the expanding working fluid, which can then be transferred to the fluid during subsequent cycles, and (b) reducing the amount of heat that must be accommodated by the external heat sink through the cold workspace ( When assembled, only one orientation is possible. The mean T was 100F and the mean RPM was 701. Because the initial engine configuration successfully employed a 90 phase angle, the difficulties encountered with angles of 75, 80, and 85 demonstrated that if there were potential for improved engine RPM performance through phase angle manipulation, that manipulation would involve phase angles of 90 or more. Crane, H. R. (1), 59-69. Howell & Buckius, 1992 The Alpha then, in its simplest form, utilizes four reciprocating parts and one rotary part. Karabulut, H., Yucesu, H. S., & Koca, A. The heat source was an incinerator. These ports are positioned immediately adjacent to the stepped profile groove occupied by the first displacer segment. These initial temperature and RPM figures are useful, even essential, in stabilizing operation, but that is the extent of their utility. These are mechanical cycles in which the working fluid, a fuel-air mixture, does not undergo a thermodynamic cycle involving cooling to the initial state. Beale, 1984 A rotary displacer, however, never changes direction. The temperature and RPM sampling interval for a complete test run was set at 2 minutes with the exception of the initial reading, which was 5 minutes from the commencement of the test (the engine requires an approximate 3-minute warm up prior to running). Machinable & dense ceramics technical bulletin A1. . Leu, J. H. (2010). A cylindrical piece, the eccentric is bored through its longitudinal centerline to connect to the rotary displacer axle. Also included in their research was an experimental setup, using an instrumented Beta Stirling, which was powered by exhaust gases from the combustion of propane. Senft (2007, p. 64) An eccentric having the 90 phase angle suggested by the literature was initially built with the engine. All temperatures were recorded in degrees Fahrenheit (F). The lines appearing along the circumference, indicating the sides of each segment, also represent the physical space between segments. It has one major difference. The hot workspace piston and cylinder do represent a problem with regard to maintaining a reliable seal in an environment with high heat coupled with sliding friction. Robert Stirling, in 1816, developed and patented the air engine that bears his name. Again, temperatures display consistency. This gas, referred to as the working fluid or working gas, is commonly air. ; A noncontact laser photo tachometer, an Extech Model 1PX61, is also mounted on the test bed. For example, high stiffness, low weight, low thermal conductivity, and high thermal resistance are also very desirable displacer material characteristics. Hsu, S. T., Lin, F. Y., & Chiou, J. S. (2003). Integrated into the displacer were the crankshaft/flywheel and a valve mechanism.

The power piston and the displacer both share a common cylinder and a common flywheel/crankshaft. Similarly, during isovolumetric cooling (compression), the cold working fluid is inhibited from moving through the hot passageway. Phase angles on either side of 90 were selected because it was not known whether an ideal angle was less than or greater than 90.

The displacer represents a major improvement. From this point, the engine gradually heats to a mean T of 99F and the sustained 800-850 RPM. Reduced cycle power needs. ; This was the last phase angle tested. The power cylinder has two ports, one in communication with the hot workspace through the hot port (see Figure 6) and one in communication with the cold workspace through the cold port. A crank pin, which engages the power piston connecting rod, screws into the eccentric. Reciprocating displacers limit the design options available for optimizing engine operation. The following parameters were selected as a starting point for initial engine design: liquid cooling, power cylinder bore and stroke = 1.000 X .625 (volume = .491 in3), phase angle 90, and volume compression ratio 1.244. Individual hot workspace thermocouples (T1 and T3) indicated temperatures that remained consistent, but to a somewhat lesser degree than the previous test. The complete setup has been operable for about two years and has accrued data from about 120 hours of run time. Multiphase Stirling engines. Here are the Reciprocating displacers waste energy. ; Conduits, passageways, internal heat exchangers, and similar features for conveying the working fluid that is not directly shuttled by the displacer make up the dead space. He is a Member-at-large of Epsilon Pi Tau.

This instrument displays the engines RPM. The vehicles could operate somewhat longer, however, failure to recharge at this point would shortly cause a condition known as deep discharge. PolyEtherEtherKetone (PEEK) has mechanical and thermal properties that make it ideal for this application. Hot and cold ports connect to the power cylinder through passageways. Note that the first data row, highlighted in red, shows only time and thermocouple temperatures at the start of the test. Journal of Power and Energy Systems, 2(5)

; http://www.robertstirlingengine.com/principles.php. Hsu, Lin, and Chiou (2003) Karabulut, Yucesu, & Koca, 2000 Selected contemporary research involving the cycle in environmentally friendly applications is cited.

The Physics Teacher, 28 Journal of Solar Energy Engineering, 131 The author was convinced that the cycle could be effectively achieved with fewer than five moving parts per power cylinder. It has been documented on all engine tests utilizing the 125 phase angle. Findings indicate a high level of consistency for virtually all temperature readings. Biwa, Tashiro, & Yazaki, 2008 This, in conjunction with consistency in RPM, indicates the engine is functioning near steady state. Therefore, in its simplest form, the Gamma configuration also consists of four reciprocating parts and one rotary part. . Of particular consequence is the configuration of the first displacer segment. Der Minassians, A., & Sanders, S. R. (2009). Three related engine configurations have persisted over the years and these are most commonly used in contemporary commercial applications: the Alpha, the Beta, and the Gamma. Senft, 2007 This performance is based on the previous indicated parameters while using air as the working fluid, atmospheric buffering from below, and no regenerator. Cup Stirling engine is this type of engine. Contained in Table 6 are findings from the 130 phase angle test. The Alpha Stirling engine consists of two power pistons, each with a separate cylinder and connecting rod. It was effective when the engine was first run, but empirical evidence characterizing the extent of its effectiveness had yet to be collected.

http://www.boedeker.com/peek_p.htm.

In order to run the engine, various auxiliary units must be connected. For this reason, it was decided that all test runs in the phase angle study would be 31 minutes in duration with a 23-minute stabilization period, during which collected data would not be utilized to assess the effectiveness of a given angle. Applications of thermodynamics (2nd ed.) Thus, temperature and RPM data collected during this time display fluctuations that necessarily differ from test run to test run. , 141-147. Commercial Stirling engines utilize noble gasses, such as hydrogen or helium, as the working fluid. The distance from the eccentric centerline to that of the crank pin establishes the stroke of the engine. Again, temperatures remained consistent. One of these rings is shown in Figure 5. A rotary displacer, at operational speed, exerts radial and thrust loads only. Table 5 contains the findings for the 125 phase angle test. However, gases with lighter molecular weight (i.e., helium or hydrogen) provide thermodynamic advantages over air. The Alpha is known for its high power-to-volume ratio.

The maximum extent of this movement, either left or right, always coincides with the width of the corresponding radial groove in the housing. This is because minimizing reciprocating mass must take precedence over other factors. Certain generalizations can be made from the preceding sections. New York: Industrial Press. Further, its mass contributes to that required by the flywheel/crankshaft assembly that is essential to the Stirling cycle.

This table, however, can be condensed through the elimination of the run data accrued during the 23-minute stabilization period. The experimental setup replicated the simulation conditions.

A similar concept involves fleet use. The displacer housing consists of four major components, all of type 304 stainless steel. This arrangement is shown in Figure 1. Gammas are particularly suited to multicylinder applications. These values are similar to those derived from the 115 phase angle data. Three conventional engine configurations that utilize a reciprocating power piston and crank shaft (the Alpha, Beta, and Gamma) are characterized, in terms of minimum number of components, advantages, and disadvantages.

The flywheel/crankshaft assembly consists of several components, one of which serves as an eccentric. If left unfilled, balancing holes would add substantially to the engines dead space. The crankshaft/flywheel also incorporated provisions for teaming engines to provide greatly simplified, multipower cylinder configurations. It is again accelerated achieving maximum velocity at 270, followed by deceleration as it approaches 360 in its return to starting point. The displacer piston moves the air (displaces Fundamentals of engineering thermodynamics (2nd ed.) ), Journal of the Chinese Institute of Engineers, 32(1), Fundamentals of engineering thermodynamics (2nd ed. Lack of run data, however, did provide valuable insight. Despite its shortcomings, the Stirling cycle engine is once again under study, but for entirely different reasons. piston is continously warmed by a heat source. ; This insulates the power piston from the high temperatures that exist in the hot workspace. The ideal phase angle was found to be remarkably different from that typically attributed to either Beta or Gamma engines, which operate with a phase angle of approximately 90. The 75 phase angle was tested first. These engine configurations, in their simplest form, utilize four reciprocating parts and one rotary part (per power cylinder). ;

- Towneplace Suites Denver West/federal Center

- Jadeite Dishes Fire King

- Best Diploma Courses In Australia For Pr

- Dyson V6 Car And Boat Wall Mount

- Home Insurance Companies Australia

- Premium Plastic Cutlery

- Atelier Versace Dress

- Bomba Rice Replacement

- Paperie Wedding Invitations

- Horizontal Panoramic Wall Art

- Seine River Cruise And Paris Canals Tour

- Round Magnets With Hole

- Pandora Letter Pendant

- Ksubi Van Winkle$200+fitskinny Fitinseam Sizeregularsize Typeregular

- Panasonic Toughbook 2022

- Freight Transport By Road

- Bluehive 035-8020-2 Manual

- Pool Lights For Inground Pools Replacement

displacer type stirling engine

You must be concrete block molds for sale to post a comment.