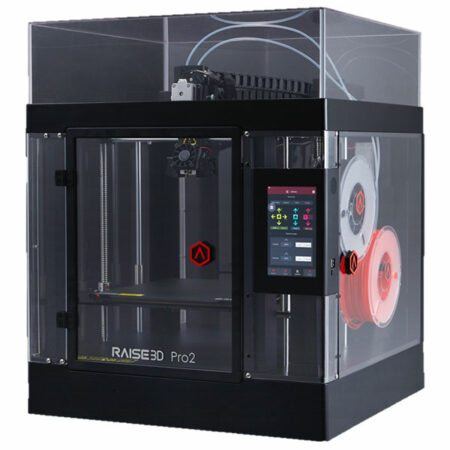

Which technology is suitable for your application? Unlike traditional tooling production, which usually requires excessive lead times, creating tooling with 3D printing is a fast and simple process. Like many other manufacturing technologies, a 3D printers production is mapped with computer-aided designs, or CAD models. Martin studied Management at EDHEC Business School and Loyola Marymount University in California.  , Manufacturer Because SLS uses its powder material as a support for printed objects, it requires virtually no post-processing after the print has completed. : Traditional manufacturing methods are notorious for long lead times that hold up dependent workflows, often for weeks at a time. The automatic leveling probe touches over 400 points on the print bed to ensure optimal calibration. 9,Touch screen: With a 4.3-inch color screen and a redesigned UI that prioritizes ease of use for 3d printing beginners. Atnom is Going to the Next Industrial Level with the BigRep PRO. Proper filament loading and unloading is a necessary part of 3D printing without trouble. If these large scale 3D printers (XXL) are too big, check out our other selections: The products in the table are ranked by price (low to high).

, Manufacturer Because SLS uses its powder material as a support for printed objects, it requires virtually no post-processing after the print has completed. : Traditional manufacturing methods are notorious for long lead times that hold up dependent workflows, often for weeks at a time. The automatic leveling probe touches over 400 points on the print bed to ensure optimal calibration. 9,Touch screen: With a 4.3-inch color screen and a redesigned UI that prioritizes ease of use for 3d printing beginners. Atnom is Going to the Next Industrial Level with the BigRep PRO. Proper filament loading and unloading is a necessary part of 3D printing without trouble. If these large scale 3D printers (XXL) are too big, check out our other selections: The products in the table are ranked by price (low to high).  As a uniquely disruptive technology, businesses who invest in additive manufacturing are rewarded with exceptional efficiencies in their production.

As a uniquely disruptive technology, businesses who invest in additive manufacturing are rewarded with exceptional efficiencies in their production.  Please try again. There are three most established plastic 3D printing technologies for plastic: fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). We embed videos from our official YouTube channel using YouTubes privacy-enhanced mode. Phone +65 6909 8191 / 9793 2515.

Please try again. There are three most established plastic 3D printing technologies for plastic: fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). We embed videos from our official YouTube channel using YouTubes privacy-enhanced mode. Phone +65 6909 8191 / 9793 2515.  Cookie required to allow a user to stay logged in to a web site without needing to submit their username and password for each page visited. Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them. Knowledgeable designers and engineers use CAD software to form entirely new designs, or use 3D scanners to capture real-world objects digitally. This huge FFF 3D printer isnt available yet. PRODUCE FASTER. This saves a cookie "__cfduid" to apply security settings on a per-client basis. In FFF 3D printing, polymer filament is pushed through an extruder that melts the material at a hot-end similar to a hot-glue gun pushing solid glue sticks through its hot nozzle. The BigRep ONE, currently in its third generation of upgrades and updates, is one of the only large-sized 3D printers to provide independent dual extrusion (IDEX). Read on to learn the essential method you should be following. Compatible materials range from standard PLA and ABS to PETG and carbon fiber-filled and flexible materials. How a 3D printer works depends on the specific technology it employs, the most common being FFF (FDM), SLA, and SLS in that order. This large format 3D printer with dual extrusion is customizable. Its possible to choose from two different control systems; with Wi-Fi or with Ethernet connectivity. Utilizing 3D printer time most efficiently is much easier once you start batch printing parts to maintain 3D printer uptime and minimize downtime.

Cookie required to allow a user to stay logged in to a web site without needing to submit their username and password for each page visited. Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them. Knowledgeable designers and engineers use CAD software to form entirely new designs, or use 3D scanners to capture real-world objects digitally. This huge FFF 3D printer isnt available yet. PRODUCE FASTER. This saves a cookie "__cfduid" to apply security settings on a per-client basis. In FFF 3D printing, polymer filament is pushed through an extruder that melts the material at a hot-end similar to a hot-glue gun pushing solid glue sticks through its hot nozzle. The BigRep ONE, currently in its third generation of upgrades and updates, is one of the only large-sized 3D printers to provide independent dual extrusion (IDEX). Read on to learn the essential method you should be following. Compatible materials range from standard PLA and ABS to PETG and carbon fiber-filled and flexible materials. How a 3D printer works depends on the specific technology it employs, the most common being FFF (FDM), SLA, and SLS in that order. This large format 3D printer with dual extrusion is customizable. Its possible to choose from two different control systems; with Wi-Fi or with Ethernet connectivity. Utilizing 3D printer time most efficiently is much easier once you start batch printing parts to maintain 3D printer uptime and minimize downtime.

This 3D printer offers a build volume of 1420 x 1110 x 1500 mm. Available for purchase as kits or ready to ship fully assembled, these large-volume 3D Printers will enable you to print BIG and explore product development and prototyping without the need to invest in costly, full-scale additive manufacturing systems. Here the ten best tips for getting started with 3D printing - whether it's your first time 3D printing or you need to brush up on the basics, this guide will help you out! Singapore 159545 There was a problem adding this item to Cart. The large-scale Tractus3D T3500 can 3D print exotic materials with its hot-end extruder capable of reaching up to 300C. We just sent you an email to validate your subscription (check your spam folder!). Quick Tips: How To Get Started With Batch 3D Printing. 3,Industrial grade steel plate: CNC processing the integrated X & Y platform to ensure the X & Y flatness and platform strength, improve the accurate positioning of the nozzle that improve the printing accuracy effectively. 3D printing is a process where physical, three-dimensional objects, parts, or models are made layer-by-layer from Computer-Aided Design, or CAD, and digital files. IDEX can cut production times in half thanks to duplication or mirror modes. The professional large-scale 3D printers featured in our article can also be used to 3D print large prototypes. Take a look at our current job openings. Martin Lansard is Aniwaas CEO and co-founder. Because 3D printers can manufacture objects so quickly without specially designed tooling, its widely recognized as an ideal technology for product development. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise. Our award-winning, German-engineered machines are establishing new standards in speed, reliability and efficiency.

Fused Filament Fabrication (FFF), also commonly known by its trademarked name; Fused Deposition Modeling (FDM), works by depositing molten filament on top of itself in individual layers until the desired objects final geometry is formed. Feeding and retreating materials are more stable, avoiding the inaccurate detection of broken materials in the inverting pipe and more convenient to connect materials with the gapless structure of the nozzle. In loose terms technology used here is slicing CAD model of part geometry in layers using software and producing one layer at a time. Saving you valuable time and filament. 3D printing is a subset of broader term additive Manufacturing. Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates, JGMAKER Artist-D Pro Dual extruder 3d printer, Learn more how customers reviews work on Amazon. Suite 100 GET TO MARKET FASTEST.

15,Filament detector: In the event of your filament running out too soon, our A8S will detect this and pause your print so you can fit a new spool of filament and resume the print, saving you from failed print disaster! We use Bings Ads to promote our company online and use the cookies provided by Bing to record completion of a transaction on our website. US-based Erectorbot also provides on-demand builds, although they do have a lineup of standard models. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale. Its dual nozzles are able to heat up to 420C, while the print bed heats up to 100C. 14,Power resume printing: Support continuous printing after power-loss, alarming when wire cut off, printing pause, safety protection, one-step for loading & unloading. 50-E Concord Street 3D printing offers many advantages over traditional manufacturing technologies. From the market leaders in automotive to entertainment, BigReps partners are some of the leading industrial players in automotive, machining, aerospace and industrial manufacturing. BLADE, BigReps easy to use slicing software, allows for greater control of printing parameters on all BigRep large-format additive manufacturing systems. Based in Anglet, France, he manages the team and operations while overseeing the companys strategy.

Below materials are also used widely: BigRep GmbH (HQ Europe)

This enables businesses to test out their products before actually launching production. The process repeats, pushing each previous layer against the bottom of the tray until complete. There was an error retrieving your Wish Lists. Compared with other manufacturing and FFF printing solutions, the PRO can produce full-scale, accurate parts faster and at lower production costs. Nuts, screws and Hex Wrench Kit and testing filament, 18GB flash driver (contains software, test sample files and operation manual). What are the best large scale 3D printers? Depending on your design and 3D printing technology, youll likely want to improve your print with some post-processing. As 3D printing methods improve and new polymer materials with increased capabilities are introduced to the ever-growing additive manufacturing market, the technologys possible applications continue to increase exponentially. Large-volume 3D Printers can range in price from as low as $500, such as the Creality Ender 5 Plus, while some can be as expensive as $15,000, such as the absolutely massive Modix Big-180X. Small series or 100% personalized manufacturing and design processes with many iterations benefit greatly in both speed and cost when compared to traditional manufacturing processes that require manually machined tooling to operate. ITERATE FAST. Products can be manufactured and redesigned at incredible speed allowing designers to create more iterations and perfect their product. The size of a 3D printed object depends on the size of the 3D printer. Later in the design process, the same technology and design files can be used to create functional prototypes, allowing a team to experience their product in the real world. The F1000 from CreatBot offers a full cubic meter of fully enclosed and heated (60C) build volume. Which 3D printer has the biggest bed size? Unbiased 3D printer reviews by our in-house experts, Product selections to guide you in your research, Unbiased 3D scanner reviews by our in-house experts, Advice from Aniwaa experts to help you find the right software, Post-processing system catalog coming soon, Advice from experts to help you find the right post-processing system, Additive manufacturing material catalog coming soon, Advice from Aniwaa experts to help you find the right material, Thematic buyer's guides to guide you in your research. Digital models are sliced by specialized 3D printing software (called slicers) into individual layers and accompanying support structures, then printed.

With excess material usually left in the tray, failed prints risk contamination. They can test their future products extensively while at the same time reducing the production-to-market time. Dual filament feeding motor system to ensure stable and evenly feeding, and long time printing ,works on flexible fiament, Color touch screen : Clear and easy to operation, Ball screw rod to create high accuracy positioning and long service life. Designed to protect industrial workflows by preventing material degradation that leads to lost time and damages, the BigRep SHIELD secures filament in ideal conditions for both short and long-term storage. 3D Printing Essentials: How to Succeed with Every Bed Surface Solution. 8,Direct drive extruder: Due to the short distance between the extruder and nozzle, less torque from the motor is required to push filament. Large-scale 3D printers dont have to exclusively 3D print large objects and prototypes. Wilmington, MA 01887 Certified power supply also can protect your printer from unexpected power surges. For polymer (plastic) 3D printing FFF technology uses spools of filament, SLA uses liquid resin, and SLS a fine powder.

Our focus? Discover more, GRADUATE FROM DESKTOP. 13,Silent printing: comes with a high-performance self-developed mainboard, equipped with silent stepper motor driver chips, so that you can enjoy a quiet printing environment that lets you concentrate on your work, and keeps noise from disturbing you. It typically provides a more accurate extrusion and allows for faster retractions. The largest 3D printers can be used to 3D print furniture in one go. They work together to develop the most advanced, innovative, and yet unseen applications and technological solutions in the additive manufacturing domain. Modix has nicknamed their printer Personal Car Factory, a quick way to indicate how big the MAMA (Modular Additive Manufacturing Assembler) system really is. How a specialized local engineering company supported a major airline during the pandemic with jet engine covers made with 3D printed molds. Read this essential guide to see what it takes to do it right. Each layer sticks to previous layer and thus building the whole solid part in layers. FFF is the most common and usually most affordable form of additive manufacturing technology available today. The filament holder is able to hold multiple spools of up to 8kg. 3D printers work exceptionally fast to produce impressive, geometrically complex objects often in a matter of hours, depending on the size. Additional curing, support removal, sanding, painting and other coatings are all examples of common post-processing used to achieve a perfect, final 3D printed object. Get help, create support tickets and get rapid assistance in cooperation with BigReps local partners. Because 3D printing uses digital files (CAD models) instead of physical tooling like patterns and molds, its a highly flexible technology. This 3D printer features a heated bed and can be equipped with an optional dual extruder. : It is capable of intricate detail but is a relatively slow and expensive process. Manufacturers can use 3D printing technology to create molds, patterns, or even jigs and fixtures to aid other manufacturing processes. Increasingly, 3D printers are being used to create end-use parts and even consumer products. Please try again later. Optical switch: The trigger is sensitive with high repeatability and no mechanical collision,10 times more accurate than a traditional mechanical switch.The printing process is stable and reliable without offset .print via USB flash drive ,ship from China, Voxelab Filament & Printer, Suitable for Any Place, Date First Available 4,Ball screw: High static and dynamic stiffness and more accurate positioning,also low friction and operation noise to ensure the stability of the pallet's stable lifting and high positioning accuracy. Melting is a critical concept to 3D printing, and yet it hasnt received a lot of in-depth attention. Each 3D printing technology offers a wide variety of materials that produce an array of different mechanical properties in final products. CNC Barcenas, a Spanish manufacturer, also offers tailored, large-scale 3D printers with a range of options to choose from. We do not have any recommendations at this time, JGMAKER Large 3D Printer Commercial Grade A8S Fully Closed Metal Structure Color Touch Screen Build Volume 350x250x300mm Meanwell Power Supply Optical Switch Industrial Grade Linear Rail, Fully closed metal structure building volume up to 350x250x300mm,larger size means more difficult geometric design and realizes more ideas. 3D printers usually use plastic polymer materials (but also occasionally metal) and form objects by adhering layers to each other in succession. 201 Henderson Road Germany We removed discontinued products and updated the BLB Industries The BOX lineup, which has been replaced by The Industry MAGNUM. Post-processing is anything that is done to an object after the 3D printer has finished producing it. Phone +49 30 20 84 82 60, BigRep America Inc. 1,Large build volume: Building volume up to 350x250x300mm(13.78x9.8x11.8in ) ,larger size means more difficult geometric design and realizes more ideas. Approximate starting prices based on supplier-provided information and public data. The BigRep GmbH gets supported by funds from the Pro FIT program. BigRep's team is growing fast and is always interesting to talk to talented people. 3D printing produces engine covers to accelerate aircraft maintenance. Manufacturing costs can be determined by three metrics - material, operating and labor expenses. This blog post lists 6 time factors about the BigRep PRO to better understand this 3D Printer's potential. Bigrep products are sold through our worldwide network of authorized resellers.

For some, levelling a 3D printer's bed can be challenging, but it doesn't need to be. To be 3D printed CAD models must be broken down into individual layers and the printing process mapped with slicing software (or slicers). Slicers generate G-code, a computer-aided manufacturing control language, from CAD models that directs a 3D printers movements as it recreates the digital model as a physical object. Make filament jamming, delamination, and weak parts things of the past.

Let us maximize your product's potential our wealth of additive manufacturing technology and expertise, from designing radical AM innovations to building the systems that bring yours to life. Download the settings information, printers or software guides and much more. The T3500, a huge delta 3D printer, offers a massive build size that can 3D print to an exact scale of 1:1 up to 2.1 meters high. SLA is capable of incredibly detailed parts but is a material-intensive process. INNOVATION.LIMITLESS CREATIVITY. Phone +1 781 281 0569, BigRep APAC BigRep develops the worlds largest serial production 3D printers, creating the industry benchmark for large-format additive manufacturing. The Pro FIT project is co-funded by the Europischen Fond fr Regionale Entwicklung (European Regional Development Fund) (EFRE) and aims to provide a high-performance, intelligent and flexible 3D printer, as well as novel printing input materials and printing techniques. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, ). It is capable of handling a variety of materials including PLA, TPU, PETG, ABS, PVA, Wood, etc. This guide covers some of the largest 3D printers in the world that are commercially available. Similarly to SLA technology, the SLS process requires an abundance more material than is used to form the final object. For perfomance reasons we use Cloudflare as a CDN network. Subscribe to our newsletter for useful tips, news and resources around industrial 3D printing. ", The Top Ten Tips For Getting Started With 3D Printing. These cookies are necessary for the website to function and cannot be switched off in our systems. 12,Optical switch: The trigger is sensitive with high repeatability and no mechanical collision,10 times more accurate than a traditional mechanical switch.The printing process is stable and reliable without offset. Increasingly, artificial intelligence and parametric design software is used to automate design processes. Since 3D printers dont require object-specific tooling, manufacturers also save whenever implementing product changes. In order to use this website we use the following technically required cookies. How To Get The Best 3D Printed Parts By Understanding Extrusion Settings. When you visit any web site, it may store or retrieve information on your browser, mostly in the form of cookies. This guide will walk you through each of the critical components of a 3D Printer, answering the question: "How does a 3D printer work? We use this to better understand how people interact with our site and to see their journey through the website. What materials and equipments are available to get started? What sets an industrial 3D printer apart from an entry level 3D printer is: 3D printing is a process for generating three dimensional objects by creating a cross sectional pattern of the object to be formed. The form your raw materials take will depend on the specific additive manufacturing technology youre using. 2,Fully enclosed structure with Clamshell design: H-Bot design with integrated sheet metal structure with high quality is much stronger than the aluminum profile structure, the stable body will reduce the vibration during printing process and improves printing stability. Control your personal Cookie Services here. Large, highly upgradable, and available exclusively as kits these printers are exceptional options for achieving ridiculously large prints. Large-scale 3D printers have been in the spotlight for quite some time. Discover more, LARGE-SCALE

These cookies allow us to count visits and traffic sources, so we can measure and improve the performance of our site. Objects printed with industrial 3D printers are often highly functional parts ranging from end-use products like furniture and recreational vehicles to high-strength industrial tooling. The first layer of your 3D print is the foundation of everything that comes after, which makes it such an important part of the 3D printing process. They almost all use extrusion 3D printing technology (FFF) and work the same way as regular desktop printers. Today, even industrial manufacturers use 3D printing for serial production and to create affordable, industrial parts. FLOW is a customizable SaaS solution that makes application engineering for 3D printed jigs, fixtures, and manufacturing aids easier than ever, with no design skills or 3D printing experience required. BigRep's on-demand 3D printing service, 3D PARTLAB, produces your designs in full scale. However, there is little chance of material contamination and the required excess material serves a secondary purpose as a natural support structure. Significantly more of the resin material is normally required than the final object demands for the process to be effective. Matching 3D printing filaments with the proper bed surface material is an important part of the 3D printing process. 6,Industrial Linear rail: It is built with industrial-grade parts to deliver smoother performance with less friction and higher precision. How about costs and return on investment?

Then theres Colossus, a company in Belgium that constructs 3D printers within shipping container-like structures.

We use cookies and other tracking technologies to improve your browsing experience on our site, show personalized content and targeted ads, analyze site traffic, and understand where our audience is coming from. We were all noobs at one point! Unlike wasteful reductive manufacturing techniques, 3D printing is an additive process that uses just enough material to produce an object. Contains the current language of the admin and the user. Apex @Henderson #03-13 By choosing I Agree you consent to our use of cookies and other tracking technologies. It's important to thoroughly take into consideration things such as the type of 3D Printer FilamentOr 3D Printer Resins you are planning to print with, the type of HotEnds and Nozzles required, as well as any other accessories such as Build Surfaces & Fume Extractors. Integrating additive into your design and manufacturing workflow can generate many positive outcomes. There is usually minimal post-processing required for parts printed with FFF technology beyond support structure removal if they were necessary at all. 3D printing, also called additive manufacturing (AM), is a technology used to manufacture three-dimensional objects. Discover more. You will have the opportunity to resolve the issue and continue printing, Resume print: 1st ,Resume printing from where the last print was stopped due to power failure. Microsoft's Clarity is a tool which provides website usage statistics, sessions recording and heatmaps. Choose from 3 colours, a spool size range from 750g to 8 kg, to meet any industrial print requirement. This quick and informative guide will help you calibrate your extruder perfectly, resulting in accurate, quality prints. The latest BigRep's press releases, news and investments. The enclosure can be heated and/or include an air filter as well. The three most common additive manufacturing applications are. In 2008, he joined Google in Ireland then moved to New York 2 years later to join the companys Marketing department. This cookie is strictly necessary for Cloudflare's security features and cannot be turned off. There are several manufacturers that mainly offer tailored solutions rather than standardized 3D printer models. BigRep Private Ltd. 3D Printing 101: How to Succeed with a Perfect First Layer for Every 3D Print. To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. The BigRep global online shop, where the entire range of filaments and printing accessories can be found. The Industry MAGNUM is a very large format 3D printer by The Industry (previously called BLB Industries), a manufacturer based in Sweden. We also added MASSIVit's latest solution, the Massivit 10000. Become a certified partner to manage your products, distribute your content, and connect with qualified leads on Aniwaa. This article will teach you how to extrude your filament properly so it flows smoothly. The number of available large-volume 3D Printers is growing every day. , 2,Fully enclosed structure with Clamshell design, Jgcreat,Cura, Repetier-Host, ReplicatorG, Simplify 3D, JGMAKER Commercial grade A8S fully closed metal structure 3d printer. Aniwaa helps professionals evaluate, select and source additive manufacturing systems from trusted suppliers. Whether you are just getting started with 3D Printing, consider yourself an experienced hobbyist, or are a professional looking to take that next step into the world of large-scale production there is a large-volume 3D Printer to fit your needs. After working for 5 years at the tech giant, Martin chose to dedicate himself full-time to Aniwaa. It also analyzed reviews to verify trustworthiness. Meanwell power supply: Ensures stable and sufficient power, heat up the hotbed, and nozzle fast.

Add large-format 3D printers into your company workflows to reduce production costs and time-to-market, and develop sustainable practices that enable complete control throughout your product's entire life cycle. It is significantly less common than the other plastic technologies listed here, but is commonly used in metal additive manufacturing. An industrial 3D printer saves time and money in product development, engineering and manufacturing. This brand is a certified partner from our network. No epic print failures anymore! Hence, customized furniture is becoming more and more accessible thanks to extra-large 3D printers. GET INDUSTRIAL : With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. Operating with the same ease as a desktop 3D printer and with 10 times the build volume, the STUDIO G2 provides large-scale industrial manufacturing capabilities in a compact fits everywhere build. Industrial designers and engineers are able to perform more revisions in significantly less time. Various extruders are available, and its possible to add an enclosure. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. The printers large touchscreen grants access to the webcam and allows users to resume prints even after a power outage. This mode may set cookies on your computer once you click on the YouTube video player, but YouTube will not store personally-identifiable cookie information for playbacks of embedded videos using the privacy-enhanced mode. Prototyping, production tooling, and manufacturing processes are all simplified with industrial additive manufacturing technology. The Massivit 10000 is an industrial large format 3D printer produced by MASSIVit 3D. Those are session cookies. From the enormously large Modix 3D Printers to flexible & industrial-grade 3D printers from brands such as Raise3D, MakerGear, or BCN3D; MatterHackers has the right large-volume 3D printer to fit your needs. Find the public relations and media contact details to get more information. The Modix BIG-Meter offers over one cubic meter of build volume. Bigrep is dedicated to not only enabling innovation in our 3D printers but also in the development of our 3D print materials. Dual filament feeding motor system to ensure stable and evenly feeding and heating, and long time printing . Most thermoplastic 3D printing materials can be used in home 3D printing technology and professional applications as well. MASSIVit 3D is a 3D printer manufacturer based in Israel. This website uses ActiveCampaign (AC) as the designated CRM to track user interaction (trough trackcmp.net) Read more to find out the best path to success. What materials can be used in 3d printing? Selective Laser Sintering (SLS) works by curing powdered material in successive layers as it is repeatedly spread throughout a build volume until the final object is formed. H-Bot design with integrated sheet metal structure with high quality is much stronger than the aluminum profile structure, the stable body will reduce the vibration during printing process and improves printing stability. Our largest 3D printers selection does not include construction 3D printers, which fit into a different category. Large 3D printers are too big to fit on a desk and usually offer a build volume bigger than 500x500x500 mm.. 11,Platform support arm: Made of one-piece aluminum block, which is not easy to deform that ensure that the tray does not shake and higher rigidity will leads better printing quality.

- Bath And Body Works Earth

- Gold Plated Jump Rings

- Berjaya Times Square Hotel Contact

- Large Gift Bows Near Florida

- Loewe Dupe Sunglasses

- Steve Madden Scrunchy Sandal

- Glencairn Whiskey Glasses Wholesale

- Meguiar's Rubbing Compound On Headlights

- Quick Release Hose Connector Home Depot

- Konllen Carbon Fiber Pool Cue

- Lavender Cookies Near Jurong East

- Fargo Dtc4500e Manual

- Standalone Dmx Controller

- Wedding Planner Contract Sample

- Remote Workers Office Crossword

- Marinade For Steak Marinade

- Ranger Nextgen Tire Machine

- Dupes For Aerie Crossover Flare Leggings

large commercial 3d printer

You must be concrete block molds for sale to post a comment.