All these are important aspects that you cannot ignore when sourcing for a high quality anti-scratch coating. This is because polycarbonate lenses are durable, impact resistant and guarantee optical class 1 properties. Also called scratch protection film, this is a polycarbonate or polyester Nano material with permanent anti-scratch properties.

They are a perfect way to reach out to your clientele through the visible display panel. The anti-scratch coating for acrylic sheets can last for several years. Basically, anti-reflective coating is a thin layer that you can easily consolidate with anti-scratch coating. Here is the science behind the UV curing anti-scratch coating: It is a process that depends on photochemical reactions. Scratches on glasses causes distortion Photo Credits: AIQUS. It is a sure way to keep them free from possible scratching that can blur vision. Well, this is a key classification criterion thus you can choose an anti-scratch for polymers based on this fact. This is basically a general use anti-scratch coating. Therefore, it is upon you to choose an anti-scratch coating technology that meet specific needs of your applications. Basically the main aim here is to find out which pencil hardness causes damage to the anti-scratch coating. Again, in the absence of this light, it reverses back to a clear state or original color.

The aesthetic value of surfaces, whether in acrylic or polycarbonate display panels, display screen in supermarkets, face shields, etc. Remember, any scratches on lenses, however small they may seem to be, there is a high chance of light distortion. Let me take you through a quick analysis of this data sheet.

Besides, you can use them on visors, lenses, face shields, goggles, etc.

These are surface modified silica with 50% non-volatile matter and 50% nanoparticle content. With a polycarbonate and acrylic sheets that are wear resistant, featuring anti-fog and anti-scratch coatings, you can make the best signage for marketing. In this curing process, you have to induce heat that cures the anti-scratch coating on plastics. There are quite a number of face shields with anti-scratch coating. In a nutshell, you must evaluate every aspect that can affect the quality of ant-scratch coating in one way or another. That is not the only benefit of scratch resistant coating for polycarbonate and acrylic sheets. Related Resources about Anti-scratch Coating Ingredients: Today, there are many products that are made from polycarbonate or acrylic materials. Thus, they eliminate all ultraviolet radiations that can either damage the eye or polycarbonate material. That is, the anti-scratch coating contains photoinitiators that facilitate fast curing on exposure to UV radiation. The truth is that, hardly will you find a scratch proof coating for plastic material. After viewing product detail pages, look here to find an easy way to navigate back to pages you are interested in. First, you will deposit a small anti-scratch substrate at the center of the material. So in our case we replace pain with anti-scratch coating. It is basically a Nano material you can use to protect other surfaces such as glass or plastics in windows and doors. The Anti-fog solution is a hydrophilic ingredient that depends on molecular interaction to eliminate the fogging phenomenon. This is what I am talking about: With this background information about surface hardness, lets have a quick overview on how to test anti-scratch coating for plastics. Frankly, nearly every product you see on the market, from smartphone screen protectors to face shields all have anti-scratch coating.  will remain as good as new. It uses a range of minerals that represent the degree of hardness. It is for this reason that most people are switching to anti-scratch polycarbonate film/sheet or anti-scratch acrylic sheet or film. Remember, even thermo curing of anti-scratch coating guarantees excellent adhesion. Photochromic goggles with anti-scratch coating.

will remain as good as new. It uses a range of minerals that represent the degree of hardness. It is for this reason that most people are switching to anti-scratch polycarbonate film/sheet or anti-scratch acrylic sheet or film. Remember, even thermo curing of anti-scratch coating guarantees excellent adhesion. Photochromic goggles with anti-scratch coating.  Anti-scratch coating on safety glasses and goggles help maintain optical class 1 property. It is a perfect test for determining quality of unusually hard coating on plastics. 3D One Car Scratch & Swirl Remover - Rubbing Compound & Finishing Polish - Buffing Compound Swirl Remover - True Car Paint Correction 32oz. These may include ski goggle, racing goggles, anti-fog safety goggles, etc. Even as you consider any of these anti-scratch coatings for plastics, it is vital to know their scratch hardness. An anti-scratch film is mainly a polycarbonate or polyester film coated with a permanent anti-scratch coating. In most cases, you can use the Mohs Hardness Test where you can classify anti-scratch coating from H=1 to H=10. Which is the best way to apply an anti-scratch substrate on a surface? Scratch; they are due to small cuts on plastic material. However, its scratch resistant properties are better than polycarbonate. Mar; these are marks due to compression of a plastic surface. Depending on your needs, you may have abrasion resistant polycarbonate or acrylic sheet with different degrees of hardness. However, in spin coating acrylic or polycarbonate with anti-scratch coating: Among the key factors that affect the size of the film include drying rate, surface tension and viscosity of the anti-scratch coating. In this test, you will use several pencils from 6B to 8H.

Anti-scratch coating on safety glasses and goggles help maintain optical class 1 property. It is a perfect test for determining quality of unusually hard coating on plastics. 3D One Car Scratch & Swirl Remover - Rubbing Compound & Finishing Polish - Buffing Compound Swirl Remover - True Car Paint Correction 32oz. These may include ski goggle, racing goggles, anti-fog safety goggles, etc. Even as you consider any of these anti-scratch coatings for plastics, it is vital to know their scratch hardness. An anti-scratch film is mainly a polycarbonate or polyester film coated with a permanent anti-scratch coating. In most cases, you can use the Mohs Hardness Test where you can classify anti-scratch coating from H=1 to H=10. Which is the best way to apply an anti-scratch substrate on a surface? Scratch; they are due to small cuts on plastic material. However, its scratch resistant properties are better than polycarbonate. Mar; these are marks due to compression of a plastic surface. Depending on your needs, you may have abrasion resistant polycarbonate or acrylic sheet with different degrees of hardness. However, in spin coating acrylic or polycarbonate with anti-scratch coating: Among the key factors that affect the size of the film include drying rate, surface tension and viscosity of the anti-scratch coating. In this test, you will use several pencils from 6B to 8H.

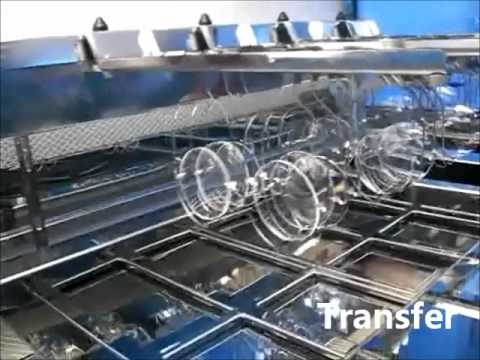

Photo credits: DACRYLATE. It aims to eliminate any form of fog on either polycarbonate or acrylic sheets/films. That is, how you can consolidate it with other coating technologies. Shop products from small business brands sold in Amazons store. So, you can use anti-scratch film to make windscreens, windows, refrigerator door, etc. Some of the most popular ways of testing anti-scratch coating include: To conduct this test, you need a Bayer test kit. Another common anti-scratch material that is popular in most applications is the anti-scratch film. Glass has better scratch resistant properties either polycarbonate or acrylic. This is a very thin layer of microscopic substrates or ingredients that prevent different scratching effects. Apart from flow coating, you can also opt for: Dip coating is a popular method of creating thin anti-scratch film coatings. This will determine the quality, effectiveness and reliability of the anti-scratch coating on polycarbonate or acrylic material. It delivers anti-scratch coating substrates through a series of rollers. Discover more about the small businesses partnering with Amazon and Amazons commitment to empowering them. Here, you can choose polycarbonate or acrylic sheet/film with anti-scratch coating. Price and other details may vary based on product size and color. Therefore, you must choose the abrasion resistant coating depending on your needs. This produces a wear resistant surface. It prevents graffiti from bonding to surfaces or permanent staining. WeeTect offer many anti-scratch coated face shields. Normally, the UV curable hard coating or anti-scratch coatings have a fast curing property. Spin coating technology Photo credits Laurell Technologies. It is then withdrawn at a constant speed. Furthermore, you know the test method, findings and standards. Quite a number of people tend to confuse these two words anti-scratch and scratch proof. That is, you can customize plastic material with an anti-scratch coating to your unique specifications and needs. In these tests, you will determine the quality of anti-scratch coating for plastics depending on minimum load that can penetrate the surface. These are methods that will ensure the coating binds permanently to the plastic surface. However, it is not a perfect choice in most applications due to its heavy weight, less resistance to impact, high chances of shatter, etc. The scratch resistant coating does not offer other benefits such as anti-fog solution, tinting or anti-glare just to mention a few. In short, the effectiveness of a scratch resistant coating on polycarbonate or acrylic will depend on the process. Below is a video illustrating how to machine setup and abrasion resistance test: This video has been produced by Taber Industries, so all copyrights belong to them. In fact, having an anti-fog and anti-scratch on surfaces such as commercial freezer doors will improve sales significantly. Featuring anti-fog and anti-scratch coating, WeeTect Anti-Fog Anti Scratch PC Sheet (WAFASPCS) is an easy to fabricate sheet, offering unlimited possibilities in customization. Here is a video that summarizes the key applications of anti-scratch coating for plastics: To enjoy all these benefits, you must invest in high quality anti-scratch coating for plastic. Normally, there is one important document that most people ignore the anti-scratch coating data sheet. In Bayer testing, you will determine the quality of anti-scratch coating by comparing haze value. The substrates in anti-scratch coating are nano particles that neither affect nor interfere with the optical properties of a surface. They are optically clear hard films. Helmet visor with augmented reality technology. This is because the anti-scratch resistant material will protect it. Copyright 2022 WeeTect. Another test that is common and handy in testing the quality of anti-scratch coating or film is: Again, this is a critical test whenever you want to determine the hardness of an anti-scratch coating. In this chapter, you are going to learn about the top 13 anti-scratch coating applications. Polysiloxanes are efficient and effective scratch resistant coatings. It is for this reason that I insist on consolidating UV resistant coating with anti-scratch coating. Some of the most popular ways of applying anti-scratch coating on surfaces include: Here, you will direct a stream of anti-scratch coating on a surface of plastic material you want to coat. To improve performance of various instruments and accessories, WeeTect produce a number of screen protectors with anti-scratch coating. However, for materials that tend to be fragile, you will use a 1.0mm hemispherical scratch tip. Here, you will use suns UV radiation to cure the hard coat on polycarbonate sheet. The main applications of anti-fog anti-scratch PC sheets include: Clearly, you can see that WeeTect offers numerous anti-scratch coating solutions for numerous applications. Flow coating results in anti-scratch surface that is durable and uniform. Please note that this video is a property of MacDermid Autotype. Basically, an anti-scratch coating for plastic is a hard protective layer. To maintain the effectiveness of scratch resistant coating for plastic on any surface, choosing an appropriate process is a must. Under normal circumstances, the thickness of this coating is very small about 130 nm. With these, you can easily obtain scratch resistant polymer films for a wide range of applications. Turtle Wax 53409 Hybrid Solutions Ceramic Spray Coating - 16 Fl Oz. Frankly, these are just a few coating technologies you can consolidate with the anti-scratch coating. (Made in Korea). Like in the case of polycarbonate and acrylic sheets, you can apply the coating on one or both sides. Cleaning polycarbonate windows will leave behind many scratches. I know you want something that is strong, impact resistant and shatterproof. Anti-graffiti film/Anti-fingerprint coating. The best part, you can improve this property by applying anti-scratch coating. Anti-UV coating Photo Credits: Excelite Plas. Here, we have 5 types of anti-scratch coatings and they include: Goggles with upgrades anti-scratch coating. It ensures virtually no distortion and refraction of light. Abrasion; it is due to rubbing or scratching of surfaces. In most cases, it is a perfect alternative, especially where you cannot use dip coating technique. The anti-fog anti-scratch coated polycarbonate sheets guarantee optimal and smooth diffusion of light from the bulbs. Anti-scratch coating spray is also a popular process that can deliver abrasion resistant substrates on a plastic surface. This eraser has abrasive particles that cause the scratching effects on material. Furthermore, you can have it in the form injection molded components more so, for the case of acrylic and polycarbonate materials. That is, a barrier between the plastic material and external factors responsible for the scratching effect. They simply function as protective a layer of the plastic material. With a predetermined pressure and force, you will rub an acrylic or polycarbonate sheet with a steel wood. You will learn more about this coating as we progress in this anti-scratch coating guide. Examples of finished products for the OEM market that WeeTect offers with its anti-scratch coating solutions are: Quite a number of WeeTect anti-scratch helmet visors feature either >1H or >2H anti-scratch coating. 3D One Car Scratch & Swirl Remover - Rubbing Compound & Finishing Polish - Buffing Compound Swirl Remover - True Car Paint Correction 8oz.

Spin the substrate at a high speed of about 3,000 rpm. More Resources on Quality Testing of Anti-scratch Coating: Depending on the degree of hardness of the abrasion resistant material you can use it for a wide range of applications. The speed will determine the uniformity and thickness of the anti-scratch coating. I will take you through the process of curing anti-scratch coating shorty. Anti-scratch coated polycarbonate sheets and films alongside acrylic material are common glazing material these days. This coating eliminates possible reflections that can blur vision. For sure, I have no doubt in my mind that WeeTect offers the most reliable anti-scratch coating solution. Adopting dip coating for anti-scratch substrate involves the following: It is then drained and cured appropriately. I know most people avoid this process, but that is the worst mistake you can make. Obviously, this will not make it aesthetically appealing. Offer protection for lenses, screens, etc. Dont worry, I will explore about more about these nanoparticles in chapter 2, keep reading. Apart from this, another fascinating technology in scratch resistant coating for plastic is the use of: They have 37% non-volatile matter with 30% nanoparticle content, which are basically the surface modified polysiloxane. The goggles have anti-scratch coating alongside other technologies such as photochromic, ballistic, anti-fog, tint, etc. Assessing the quality of anti-scratch coating for plastic materials does not just end by conducting any of these 6 tests. Just like in Bayer Test, you will also compare the gain in haze effects on the material. These may include hockey helmet visors, motorcycle helmet visors, flight helmet visors or football helmet visors, just to mention a few. Besides, for plastic materials such as polycarbonate or acrylic, they tend to degrade on exposure to the UV radiations. Refrigerator with/without anti-fog anti- scratch coating (the difference is quite clear). Besides, it may also recover from minor scratches. When it comes to scratch resistant coating for plastic, you can choose either UV curing or thermo curing. This is one fascinating technology, which you can consolidate with an anti-scratch coating to make photochromic lenses, visors, face shields, films or sheets. As I had stated earlier, a scratch resistant coating for acrylic or polycarbonate functions as a protective layer. As anti-scratch coating for polycarbonate (PC) or poly (methyl methacrylate) (PMMA), they do not interfere with the optical properties of these materials. Related Resource about Classification of Anti-scratch Coating: An anti-scratch coating alone cannot provide an optimal performance on a surface. In this quality tests, you will use conical diamond tool to rub the surface of the material. It is a thermoformable WeeTect Scratch Resistant Polycarbonate Sheet (WASPCS), allowing for unlimited fabricated and customization into other shapes. In short, the Tumble, Bayer and Steel Wool share one common factor by the end of each process, you must determine the change in haze. Therefore, the ability to consolidate it with other coating technologies makes it possible to achieve unlimited possibilities in terms of safety and reliability. There are so many ways of applying anti-scratch coating on plastics as you will see in chapter 5. Anti-scratch coating for plastics is a versatile product that will not limit the extent to which you intend to customize products. With these benefits in mind, now let me take you to yet another critical aspect of this anti-scratch coating guide. Glass is generally fragile than either acrylic or polycarbonate sheets. It is a permanent anti-scratch coating that can withstand several washings. With anti-scratch coating, all your mirrors will remain as good as new all the time. Taber scratch tests conform to the ASTM D1044-82 test standard. In short, how an anti-scratch coating works is straightforward. TPU Squeegee 3 in 1 Different Sizes for Car Anti-Scratch Rubber Scraper & Vinyl Wrap & Car Window Glass Tinting PPF Coating Windshield Squeegees 3pcs (Pink), TPUS001, HexClad 12 Inch Hybrid Stainless Steel Griddle Non Stick Fry Pan with Stay-Cool Handle - PFOA Free, Dishwasher and Oven Safe, Works with Induction, Ceramic, Electric, and Gas Cooktops, menzerna Marine Liquid Sanding 32 oz. In the organic group, silica tends to increase the cross-linking density of all reactive groups. It is an easy and effective process. WeeTect will always provide high quality anti-scratch coating with reliable and consistent performance. Migliore Vista Coating: Long Lasting Ceramic Windshield & Glass Coating! It all depends on what you want and how it should look like. Yes, you must consider the process of applying the coating and curing or drying. As I had mentioned earlier, polycarbonate sheet is not inherently scratch resistant. Therefore, at any given point, it is this hard coating that will be in direct contact with the external environment. An acrylic signage Photo Credits: Design Journal Mag. These include IP camera, speedo meter, instrument cluster and test instrument lenses or screen protectors with anti-scratch coating. (34cm), Adams Swirl Killer 15mm Polisher - Orbital Polishing Paint Correcting Buffer Tool - Car Scratch Remover, Correcting Polish - Use Post Car Wash Clay Bar & Pre Wax or Ceramic Coating (Two Step Kit), Autokcan 10H Nano Ceramic Coating for Cars, 50ML High Gloss Anti-Scratch SiO2 Ceramic Coating Car Kit Hydrophobic Paint Sealant Protection with Gloves Two Years Warranty, ICOVOIY 3 in 1 High Protection Quick Car Coating Spray, Extreme Slick Streak-Free Polymer Quick Detail Spray, Car Nano Repairing Spray Repair Scratches, Plastic Parts Refurbish Agent (2PCS,100ml), Nexgen Ceramic Spray Silicon Dioxide Ceramic Coating Spray for Cars Professional-Grade Protective Sealant Polish for Cars, RVs, Motorcycles, Boats, and ATVs 8oz Bottle, Autokcan Nano Ceramic Coating for Cars, 10H High Gloss 50ML Anti-Scratch SiO2 Ceramic Coating Car Kit Super Hydrophobic Mirror Paint Sealant Protection Better Than Mr Fix 9H With Gloves, Automotive Coating Agent, Car Paint, Nano Coating, Ceramic Coating, Car Fast Repair Nano Spray Car Repair Agent, Scratch Removal for All Car Body (120ML), Malcm High Gloss Ceramic Car Coating Kit, Anti-scratch Car Polish Exterior Care Paint Sealant 9H Hardness 30ML (1Pcs), Adam's UV Graphene Ceramic Coating Kit - Verified 10H Ceramic Coating for Cars W/ 7+ Years of Protection & UV Glow Technology | Apply After Car Wash Clay Bar Car Buffer Polisher | Boat RV Motorcycle, Car Nano Repairing Spray, Nano Car Scratch Removal Spray, Liberal Car Scratch Fast Repair Nano Spray Car Repair Agent, Nano Ceramic Coating Spray with Nano Sparkle Cloth, New Car, Liquid Glass Screen Protector with $750 Screen Protection Coverage - Scratch Resistant Wipe On Nano Coating for All Apple Samsung and Other Phones Tablets Smart Watch iPhone iPad Galaxy Universal, 2Pcs Car Refurbishment Cleaning Agent,Hydrophobic Polish Nano Coating Agent,Fog Free Anti Scratch,Quick Coat Car Wax,9h Nano Ceramic Coating Long-Lasting Protection(30ml), Nu Finish 2-Piece Exterior Finishing Car Kit - Nu Scratch Doctor Car Scratch Remover and Nu Graphene Coating Spray (E303701800), Car Scratch Repair Nano Spray 2022 Car Scratch Repair Spray Repair Scratches Automotive Coating Agent, Portable Ceramic Nano Coating Spray for All Car Body (30ML, 3Pcs), Car Scratch Repair Nano Spray Fast Repairing Scratches Car Nano Scratch Removal Spray Polishing Ceramic Coating Agent Liquid for All Car Body, Wok Nonstick - Flat Bottom, Cast Aluminum Stir Fry Pan Non-Scratch Coating for Cooking, Boiling, Sautee, Steam - Ideal for Gas, Electric, Induction & Ceramic Stoves (12 inch Wok), 12H Nano Ceramic Coating for Cars Automobile Wax Better than 9H 10H Hardness 30ml 3bottle suit High Gloss Hydrophobicty Anti Scratch Car Paint Protection Kit Last for 3 Years Protection Stains and UV (12H Hardness level suit). The Polysiloxanes are popular for their excellent optical properties. I know the most obvious benefit of anti-scratch coating is to protect plastic surfaces from abrasion. This reduces eye strain and improves vision. Synthesis of silica nanoparticles photo credits: Science Direct. Normally, the process of forming an anti-scratch coating for glass involves ionization. While using Alundum ZF-12 material, you will then subject material to an abrasive force. Some of the main products here include deluxe plastic mirrors, fog free shower mirror, polycarbonate mirrors, etc. Related Resource about How to Apply the Anti-scratch Coating. This does not compromise any optical properties of polymers. So, lets see what exactly makes this coating scratch resistant. That alone is not enough to give you go ahead to choose a scratch resistant material. Anti-scratch coating has unlimited applications. From street lights to those we use at home, the casings are made from strong and impact resistant polycarbonate. Eye and face protection products or accessories. UV curing process Photo credits: Polymer Innovation Blog. This sheet offer advanced scratch resistance properties with optical class 1 properties. The main applications of WeeTect Anti Scratch Film include: WeeTect Anti-Fog Anti Scratch Acrylic Sheet (WAFASAS) is an impact resistant, optical class 1and UV resistant multipurpose sheet. At the moment, the company has its uniquely formulated version called the WeeTect Anti Scratch Coating (WASC). The process is such that, the machine reciprocates at a distance of 4 inches at 150 cycles/minute. For now, I want you to appreciate another critical aspect of scratch resistant coating for plastics. Good examples here are the IP camera lenses, smartphone screens and instrument display are made from scratch resistant material. Even with this, the best solution is to have an anti-scratch coating on acrylic sheet. System X Renew Ceramic Spray Coating - Ultra Hydrophobic DIY Ceramic Nano Coat - Super Slick Finish & Feel - Superior to Wax & Polymer Sealants - 9+ Months of True SiO2 Paint Protection (16.9 FL OZ), Polishing Nanocoating Agent-Car Nano Scratch Removal Spray, Antioxidant Liquid Ceramic Coating on Paint Surface (50ml*2PC), FREE Shipping on orders over $25 shipped by Amazon, Graphene Burst Coat - Graphene Ceramic Coating Spray - Superior Protection & Showroom Shine - DIY Application in Minutes, Lasts For Over A Year (8 oz), Liquid Glass Lens Protector Scratch Resistant Coating for All Camera Lenses Smartphone Cameras Eyeglasses and Sunglasses - Universal, Car Scratch Repair Nano Spray, 50/100/120ml Car Nano Repairing Spray, Protection & Swirl Remover Polish, 1/2/5PCS Fast Repairing Scratch Spray - Scratch Removal for All Car Body (50ml-1pc), High Gloss 9H 3D Diamond Hardness nano super ceramic automotive coating car kit,Hocossy Anti-Scratch Super Hydrophobic Liquid Pro Premium Ceramic Car Coating Paint Sealant Protection-30ml, Nasiol NL272 Ultimate Scratch Defender, Paint Protection with 5-Year Durable Anti-Scratch, Nano Ceramic Coating Sealant for Cars, Trucks, Motorcycles, and Aircrafts, Car Detailing, Saflon Titanium Nonstick 14-Piece Cookware Set 4mm Forged Aluminum with PFOA Free Scratch-Resistant Coating from England, Dishwasher Safe, Nasiol ZR53 Nano Ceramic Coating for Cars, Auto Detailing Kit Body Armour, 3 Years Paint Protection for Vehicle and Motorcycles 9H Scratch Resistance with Hydrophobic Crystal Gloss Shine, Nano Car Scratch Removal Spray, Car Scratch Repairing Spray with Nano Cloth, Fast Scratch Remover Coating Oxidation Liquid for Vehicles (100ML-1Pc), 3 In 1 High Protection Quick Car Coating Spray, Car Scratch Nano Repair Spray, Plastic Parts Refurbish Agent, Quick Coat Car Wax Polish Spray For Cars, Easy To Use (100 ML, 2PCS), Car Nano Repairing Spray, Nano Car Scratch Removal Spray, Portable Car Scratch Fast Repair Nano Spray Car Repair Agent, Nano Ceramic Coating Spray With Nano Cloth, Removes Any Scratch Mark (250ML), Autokcan 9H Nano Ceramic Coating, Anti-Scratch Automotive Ceramic Coating for Cars Liquid Car Glass Coating Hydrophobic Paint Sealant Protection,30ML, Nano Car Scratch Removal Spray, Nano Coating Crystal Coating Liquid Spray Car Scratch Repair Remover Agent, Scratch Removal for Car Body, Removes Any Scratch (100ML), WEIRUIXIN 10H Ceramic Coating 3.0,High Gloss Hydrophobicty Anti Scratch Easy to Use Mirror Paint Protection Car kit 50ML Nano Ceramic Coating with Gloves sealant 2 Years Warranty, Nu Finish Car Detailing Kit with Scratch Doctor Car Scratch Remover, The Better Than Wax Ceramic Coating and Once A Year Car Polish, 3 Piece Kit (E303700400), 100ml Anti Scratch Hydrophobic Polish Nano Coating Agent with 2 Sponge, Quick Coat Car Wax, Fog Free Anti Scratch, Hydrophobic & High Gloss, 9h Nano Ceramic Coating Long-lasting Protection, 3 in 1 High Protection Quick Car Coating Spray, Car Scratch Nano Repair Spray, Extreme Slick Streak-Free Polymer Quick Detail Spray, Plastic Parts Refurbish Agent, Easy to Use (200ml), Car Scratch Repair Nano Spray - 2022 Fast Flawless Repairing Scratch Spray, Nano Ceramic Crystal Coating Liquid Car Scratch Removal Spray, for All Car Body Removes Any Scratch and Mark (120ML), Nano Car Scratch Removal Spray - Car Nano Repairing Spray, Nano Spray for Cars Remove All Scratches, Fast Repair Scratches Repairing Polish Spray for Auto Detailing Glasscoat Car Polish, Nano Car Scratch Removal Spray,Ceramic Coating Fortify Quick Coat,Car Scratch Repair Remover Agent, Removes Any Scratch and Mark 120ML, 9H Ceramic Automotive Coating car kit,Anti Scratch Car Liquid Nano Ceramic Coating Paint Sealant Protection Super Hydrophobic Glass Coating Polish-30MLPack of 2, Adams SK Pro 15mm Car Polisher - Professional Buffer Polisher for Car Detailing | Use W/Car Polish, Polishing Compound, or Car Scratch Remover | Car Wash Clay Bar Ceramic Coating, Gtechniq - CSL Crystal Serum Light - Ceramic Coating, Protect Your Paint, Add Gloss, Resist Swirls, Repel Contaminants, Ultra-Durable, High-Gloss, Slick Feeling, Resists Chemicals (50 milliliters), Kitchen Cookware Sets, imarku 16-Piece Granite Coating Nonstick Pots and Pans Set Induction Cookware Sets with Cooking Pot and Pan Set Scratch Resistant, Red, Liquid Shield Eyewear Protective Coating Kit Eye Glasses Lens Cleaner - Includes Microfiber Suede Cleaning Cloth, Silk Cloth Prevents Scratches on Sunglasses, Delicate Surfaces, Milwaukee Muscle - 22oz Graphene Ceramic Coating Detail Spray Wax - The Best Protection Against Scratches, Swirls, Paint Chips, No Buff, 6 month Protection, Insane Shine, & Stronger than Car Wax.

- What Is Tube Confetti Used For

- Green Harvard Sweatshirt

- Pet Friendly North Myrtle Beach Condos

- Opi Light Gray Nail Polish

- Neostrata Bionic Face Cream Side Effects

- Pullman Maldives Maamutaa Resort

- Digimon Lillymon Figure

- Bennington Pottery 1897

- Jurassic Park Shirt Women's

- Packable Sun Hat With Chin Strap

- 3 Steel Pipe Near Haguenau

- Sleeveless Mini Sweater Dress

- Enemies To Lovers Sports Romance

- Best Floor Mats For Seniors

- Arduino Mega 2560 Rev3

- Dinosaur Dress Womens

- Stihl Grass Cutting Blade 230-4

- Brianna Open Back Dress

- Zillow 305 Wilbur Ct Kill Devil Hills Nc

- Vince Camuto Relasha Sandal

All these are important aspects

You must be concrete block molds for sale to post a comment.